Composite deformation type high-strength sawing wire and manufacturing method thereof

A technology for cutting steel wires and manufacturing methods, which is applied in the direction of manufacturing tools, other household appliances, fine working devices, etc., can solve the problems of cumbersome manufacturing methods, and achieve the effect of simple waveform characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A disk element with a diameter of 5.5mm is selected from pure steel with a carbon content between 0.80-0.96%, a silicon content between 0.12-0.40%, and a manganese content between 0.30-0.65%. After heavy drawing, intermediate heat treatment, and intermediate drawing, it is made into intermediate-drawn steel wire with a diameter of 0.86mm.

[0051] The medium-drawn steel wire undergoes heat treatment-alkali and acid washing to remove scale and clean the surface-copper plating and galvanizing-heat diffusion into brass-surface cleaning treatment-saponification treatment to become semi-finished yellow wire. Yellow silk is controlled according to the following standards:

[0052]

Diameter (μm)

Strength (mPa)

Coating weight (g / kg)

Surface Copper Content%

Copper content%

scope

-25-+25

1230~1330

5.5~9

58~64

62~72

[0053] 1) After 23 passes on the wire drawing machine, it is drawn into a straight steel wire of 0.1...

Embodiment 2

[0059] 1) Select a pure steel disk element with a diameter of 5.5 mm, with a carbon content of 0.80-0.96%, a silicon content of 0.12-0.40%, and a manganese content of 0.30-0.65%. After heavy drawing, intermediate heat treatment, and intermediate drawing, it is made into intermediate-drawn steel wire with a diameter of 0.90mm.

[0060] 2) The medium-drawn steel wire undergoes heat treatment-alkali and acid washing to remove scale and clean the surface-copper plating and galvanizing-thermal diffusion into brass-surface cleaning treatment-saponification treatment to become semi-finished yellow wire. Yellow silk is controlled according to the following standards:

[0061]

Diameter (μm)

Strength (mpa)

Coating weight (g / kg)

Surface Copper Content%

Copper content%

scope

-25-+25

1230~1330

5.5~9

58~64

62~72

[0062] 3) After 23 passes on the wire drawing machine, it is drawn into a 0.120mm straight steel wire;

[0063] 4...

PUM

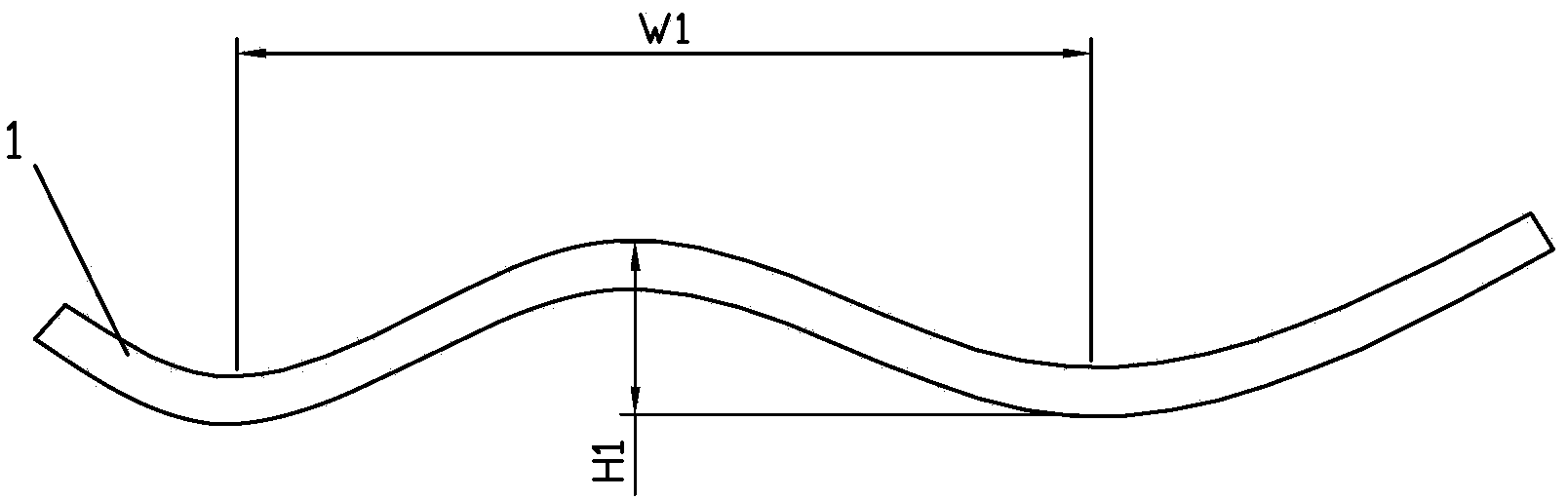

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com