Production method for yellow phosphorus

A production method and technology for yellow phosphorus, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of insufficiency, difficulty in producing high-purity yellow phosphorus, and large equipment and labor consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

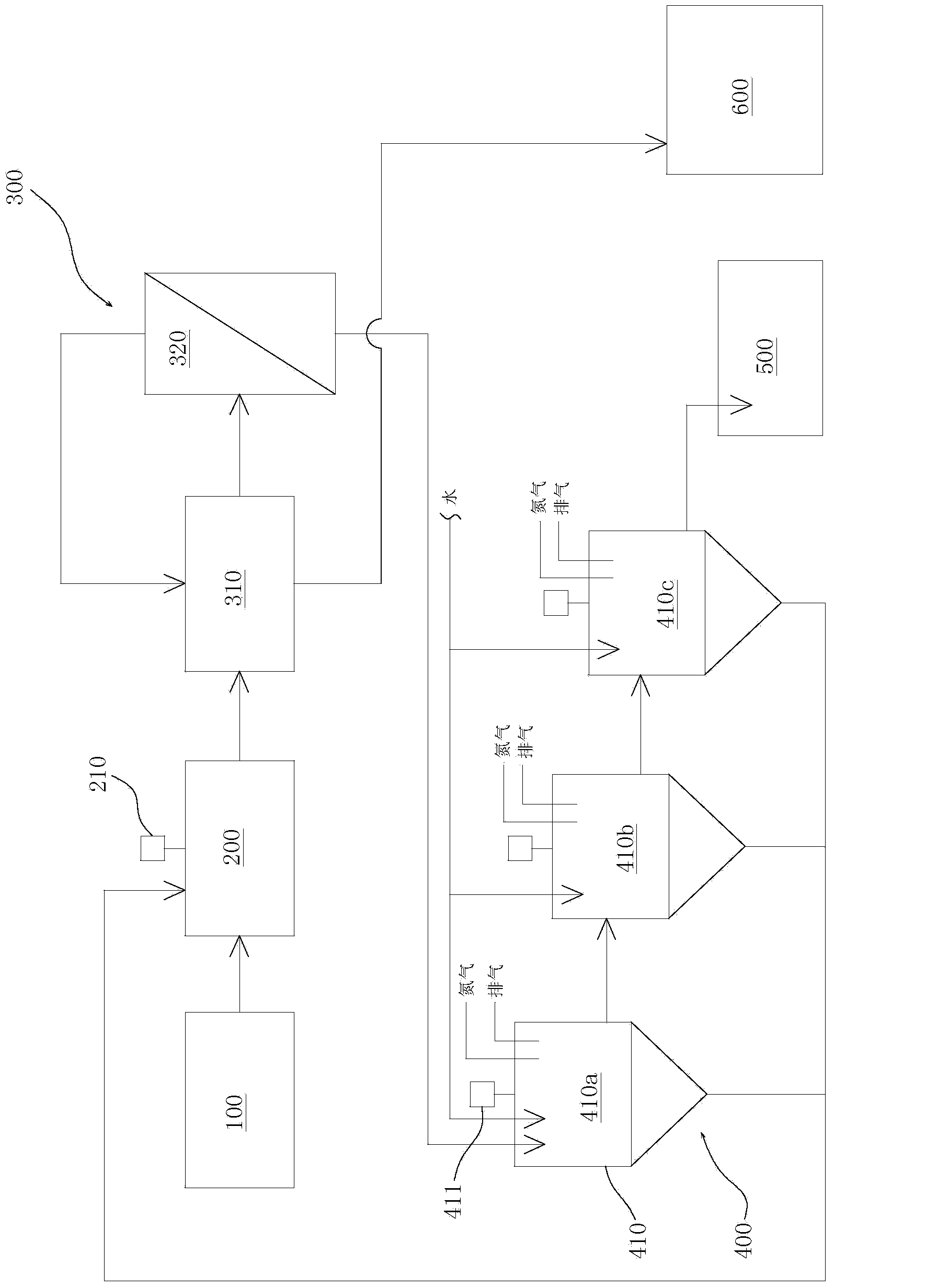

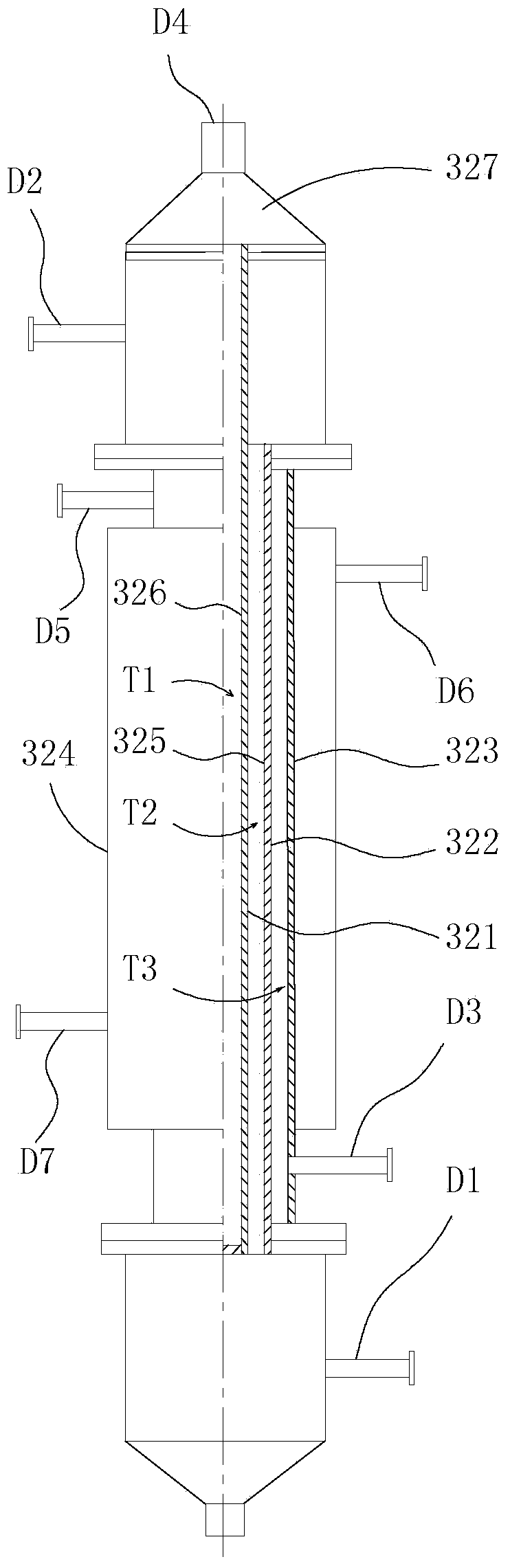

[0024] Send the crude phosphorus into the reactor 200, make the crude phosphorus enter the hot water (purified water, the same below) that is pre-passed into the reactor and keep the temperature at 75°C, and then stir with the stirring device 210 until the yellow phosphorus is completely melted Then add activated carbon powder with a particle size of 100-500 μm and an amount of 0.2% by weight of crude phosphorus to the mixed slurry of yellow phosphorus and water, and then stir for 30 minutes; secondly, the slurry is stirred and then sent to the middle tank 310, Then the slurry in the middle tank 310 is pumped to the cross-flow filter 320 for cross-flow filtration. The filtration temperature during cross-flow filtration is kept at 75°C, and the pressure difference between the first channel T1 and the second channel T2 The pressure difference between the second channel T2 and the third channel T3 is controlled at 0.05MPa, the pressure difference between the second channel T2 and ...

Embodiment 2

[0026] Send the crude phosphorus into the reactor 200, make the crude phosphorus enter the hot water (purified water, the same below) that is pre-passed into the reactor and keep the temperature at 75°C, and then stir with the stirring device 210 until the yellow phosphorus is completely melted Then add activated carbon powder with a particle size of 100-500 μm and an amount of 0.3% by weight of crude phosphorus to the mixed slurry of yellow phosphorus and water, and then stir for 60 minutes; secondly, the slurry is stirred and then sent to the middle tank 310, Then the slurry in the middle tank 310 is pumped to the cross-flow filter 320 for cross-flow filtration. The filtration temperature during cross-flow filtration is kept at 75°C, and the pressure difference between the first channel T1 and the second channel T2 The pressure difference between the second channel T2 and the third channel T3 is controlled at 0.075MPa, the pressure difference between the second layer channel ...

Embodiment 3

[0028] Send the crude phosphorus into the reactor 200, make the crude phosphorus enter the hot water (purified water, the same below) that is pre-passed into the reactor and keep the temperature at 75°C, and then stir with the stirring device 210 until the yellow phosphorus is completely melted Then add active carbon powder with a particle size of 100-500 μm and an amount of 1.2% by weight of crude phosphorus to the mixed slurry of yellow phosphorus and water, and then stir for 100 minutes; secondly, the slurry is stirred and then sent to the middle tank 310, Then the slurry in the middle tank 310 is pumped to the cross-flow filter 320 for cross-flow filtration. The filtration temperature during cross-flow filtration is kept at 75°C, and the pressure difference between the first channel T1 and the second channel T2 The pressure difference between the second layer channel T2 and the third layer channel T3 is controlled at 0.3 MPa, the flow velocity of the slurry in the second la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com