Operational controls for inert gas blanketing for Andrussow process

A gas, ternary gas technology, which is applied in the preparation/purification/separation of hydrogen cyanide, chemical instruments and methods, inorganic chemistry, etc., and can solve the problem of no disclosure of inert gas covering system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

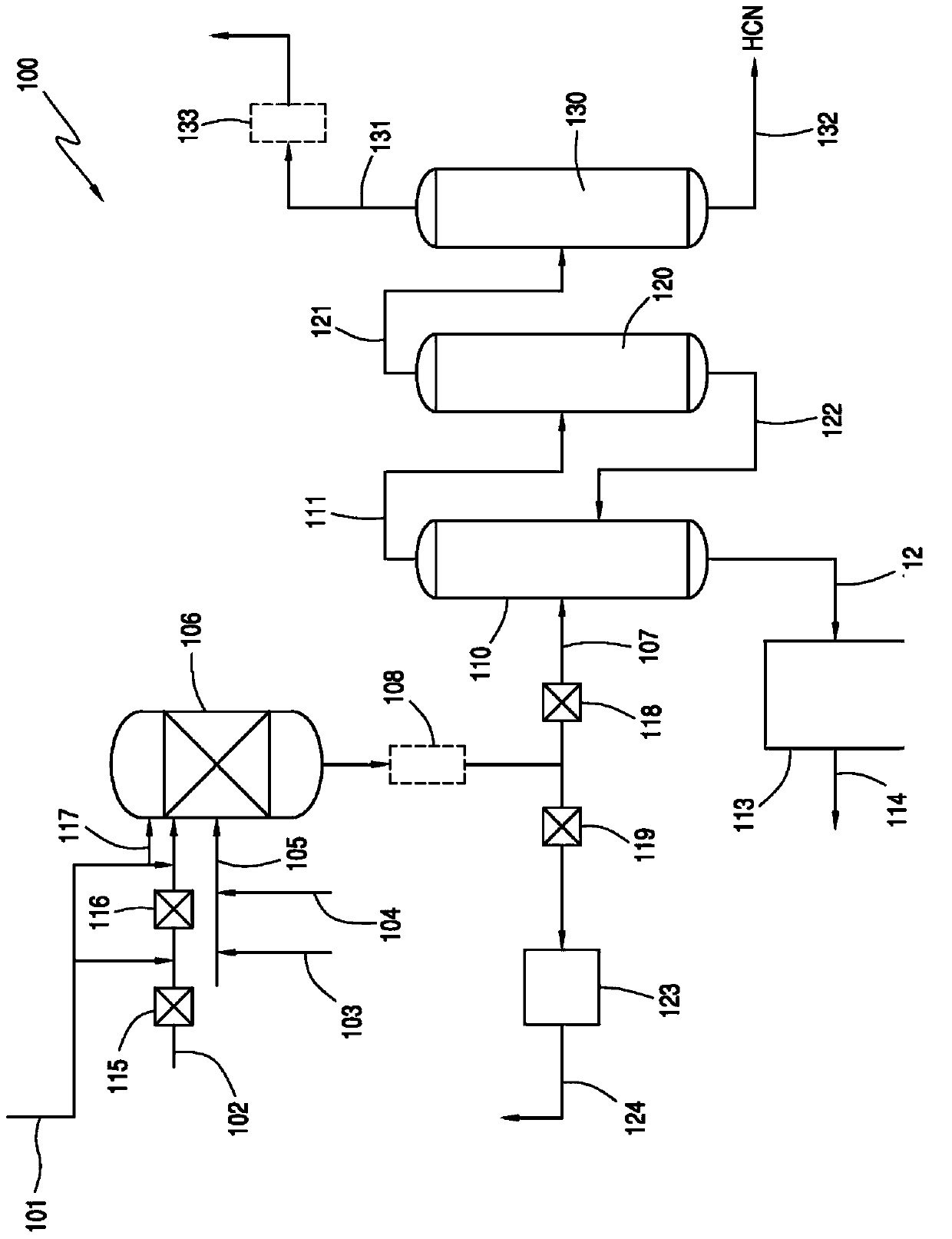

[0070]A ternary gas mixture is formed by combining pure oxygen, an ammonia-containing gas, and a methane-containing gas. The molar ratio of methane to oxygen in the ternary gas mixture was 1.3:1 and the ratio of methane to oxygen in the ternary gas mixture was 1.2:1. A ternary gas mixture comprising from 27 to 29.5 volume percent oxygen is reacted in the presence of a platinum / rhodium catalyst to form a crude hydrogen cyanide product. A gas sensor is present to measure the oxygen content in the crude hydrogen cyanide product before it enters the ammonia and HCN separation step. The sensor measures oxygen levels using chromatography. A sensor reporting an oxygen level of 0.5% by volume indicates a system failure and activates the inert gas blanket system. The inert gas is nitrogen. The conduit for introducing the oxygen-containing gas into the reactor has two valves, a first oxygen valve and a second oxygen valve in series, the second oxygen valve being downstream and closer...

Embodiment 2

[0072] The crude hydrogen cyanide product was prepared according to Example 1. The crude hydrogen cyanide product is directed through an ammonia absorber, an ammonia scrubber, and an HCN absorber to form an off-gas stream. There are sensors to detect the oxygen content in the exhaust gas stream. Sensors reporting oxygen levels greater than 2% by volume indicate a system failure and activate the inert gas blanket system. The operation of the inert gas is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com