No-fines recycled-aggregate pervious concrete for district roads and preparation method

A technology of permeable concrete and recycled concrete, applied in sustainable waste treatment, solid waste management, climate change adaptation, etc., can solve problems such as urban waterlogging, casualties, property loss, etc., to reduce ground water, improve the environment, configure The effect of simple and efficient technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

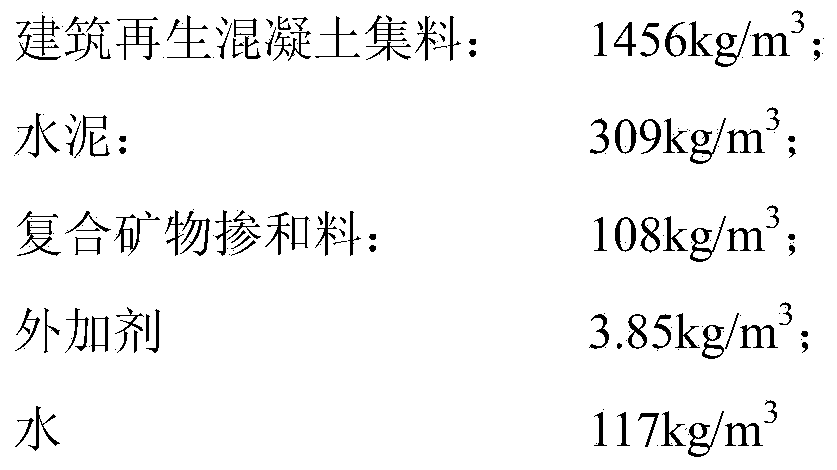

[0024] This implementation case is used for the sand-free recycled aggregate permeable concrete used in the roads of the residential area. The quality components of the sand-free recycled aggregate permeable concrete used are as follows:

[0025]

[0026] The above-mentioned architectural recycled concrete aggregates come from the recycled aggregates formed by crushing and processing the demolished components of a concrete frame structure (primary concrete strength C30-C35). 12.4%3 , mud content (by mass) 0.6% 3 >1350kg / m 3 , water absorption 2.5% ≤ 5.0%, bulk porosity 48%. Recycled concrete aggregates for construction are subjected to alkalization treatment before configuration, and are used under the condition of saturated surface dryness.

[0027] The above cement is Portland cement with a strength grade of 42.5 MPa.

[0028] The above-mentioned composite mineral admixture SiO 2 Content 90%, specific surface area ≥ 400kg / m 2 , 7d and 28d activity indices are not less...

Embodiment example 2

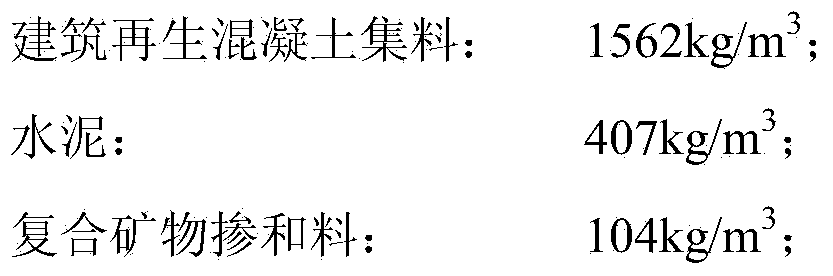

[0032] This implementation case is used in the configuration technology of sand-free recycled aggregate permeable concrete for roads in residential areas. The quality components of the sand-free recycled aggregate permeable concrete used are as follows:

[0033]

[0034]

[0035] The building recycled concrete aggregates are derived from the recycled aggregates formed by crushing and processing the demolished components of a concrete frame structure (primary concrete strength C30-C40). Value 11.7%3 , mud content (by mass) 0.5% 3 >1350kg / m 3, water absorption 2.4% ≤ 5.0%, bulk porosity 50%. Recycled concrete aggregates for construction are subjected to alkalization treatment before configuration, and are used under the condition of saturated surface dryness.

[0036] The cement is Portland cement with a strength grade of 42.5MPa.

[0037] The composite mineral admixture SiO 2 Content 90%, specific surface area ≥ 400kg / m 2 , 7d and 28d of The activity index is not lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com