Strong-flavor type hot-pressing and refining small unit process

A small-unit, strong-flavor type technology, applied in the project field, can solve problems such as the decline of strong fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

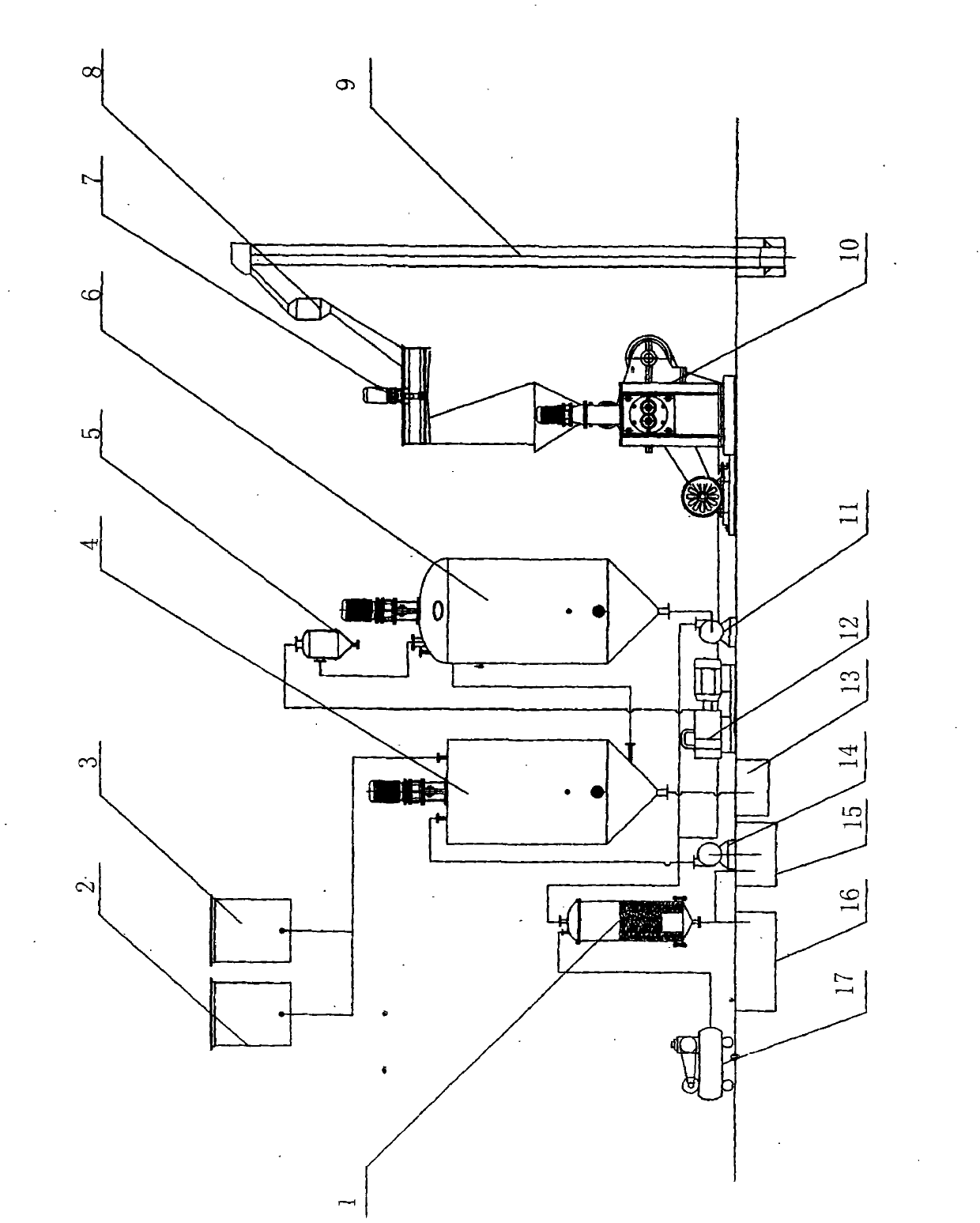

[0009] Such as figure 1 The process involved in this project shown in the figure, the edible oil is crushed and transported to the hoist 9; the hoist 9 is transported to the iron remover 8, and the oil is transported to the frying pan 7 after iron removal; Oil heating; the oil is adjusted by direct steam to achieve the effect of conditioning and improving the oil yield. After conditioning, the oil is transported to the oil press 10 for continuous pressing to extract oil, and the crude oil is transported to the special filter 1 through the oil pump for filtration; since the process is equipped with two special filters, the two filters alternately clean up solid impurities; the filtered The crude oil is transported to the crude oil tank 15 for temporary storage. The oil cake is sent to the leaching workshop for leaching to produce edible oil or sent to the cake storage for later use. The filtered crude oil is pumped into the refining pot 4 through the crude oil pump 14, and br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com