Truss structure of triangle-section concrete-filled steel tube

A technology of steel tube concrete and truss structures, which is applied in the direction of load-bearing elongated structural components, structural elements, building components, etc., which can solve the problems of complex weld stress, difficulty in ensuring connection quality, and difficult construction, and achieve quality Guaranteed, clear stress and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

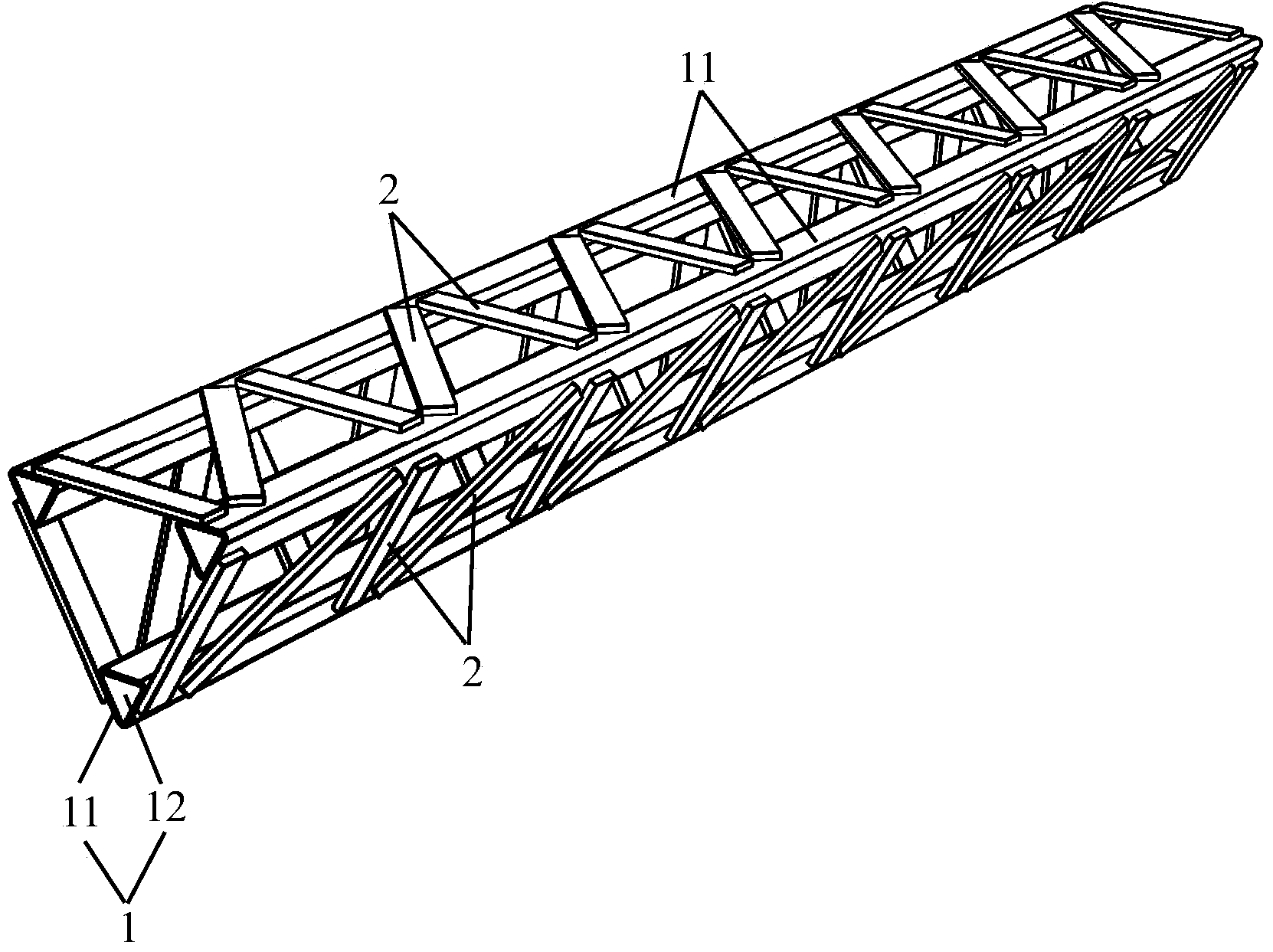

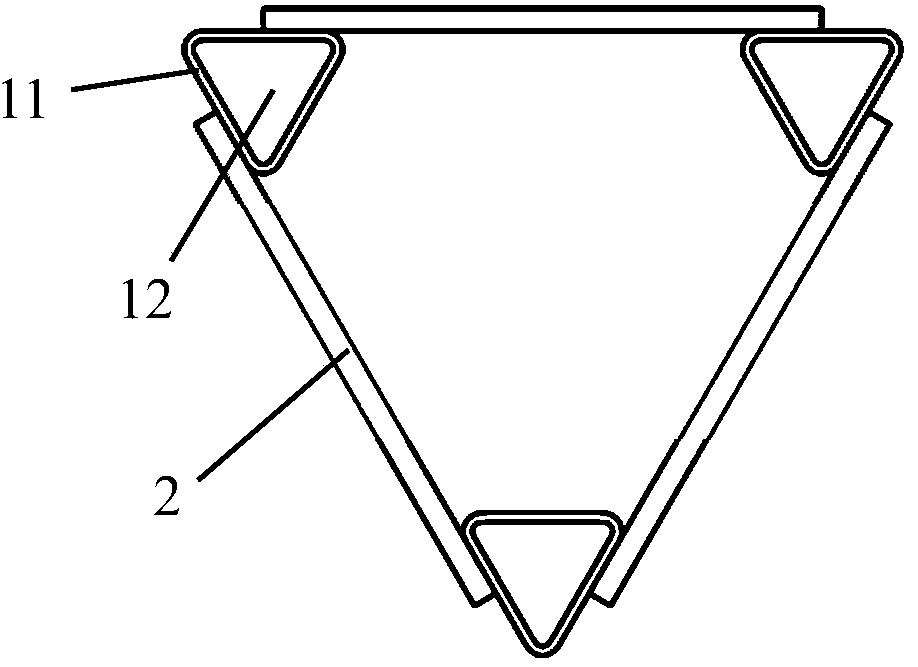

[0015] like figure 1 and figure 2 As shown, the triangular-section concrete-filled steel pipe truss structure of the present invention includes three chords 1 and a plurality of webs 2, the three chords 1 are distributed in a triangle and are connected by the plurality of webs 2 to form a three-dimensional space structure, The chord 1 includes a steel pipe 11 and concrete 12, the cross section of the steel pipe 11 is triangular, the concrete 12 is filled inside the steel pipe 11, and the web 2 is a steel web. The steel pipe 11 is made of ordinary carbon steel, stainless steel or refractory steel; the concrete 12 is ordinary concrete, high-strength concrete, high-performance concrete, recycled aggregate concrete or lightweight aggregate concrete; the web 2 is steel plate.

[0016] The ratio of the outer length of the steel pipe 11 to the wall thickness of the pipe is greater than 20, so thin-walled steel pipes can be used to reduce material costs.

[0017] The cross-section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com