Anti-rust device for pre-embedded exposed steel bars in construction projects

A technology for construction engineering and steel bars, which is applied in the field of pre-embedded anti-rust devices for exposed steel bars in construction engineering, which can solve problems such as corrosion, and achieve the effects of weakening the durability of buildings, slowing down corrosion, and blocking the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

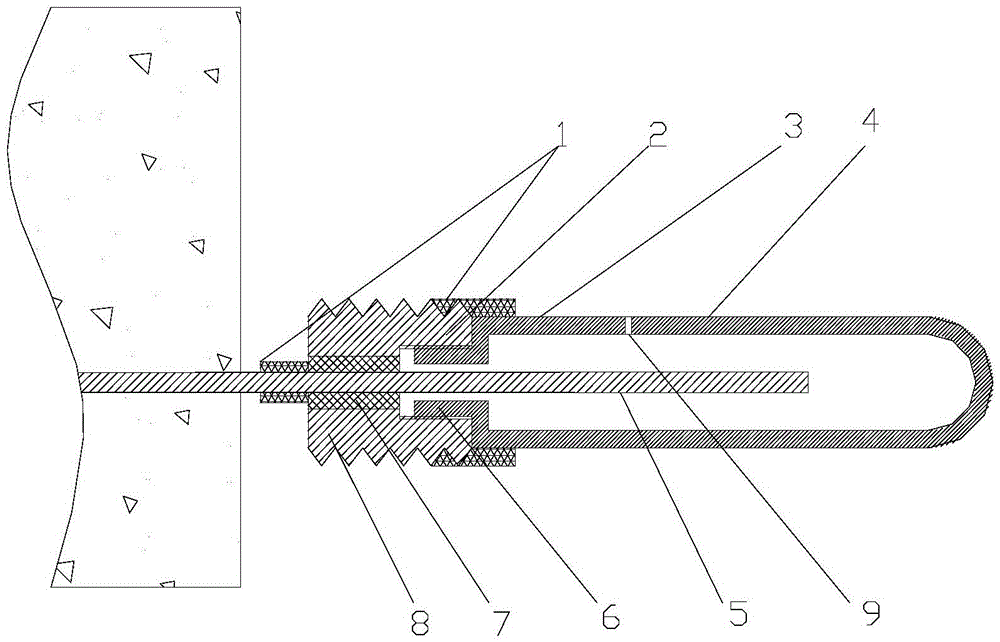

[0020] figure 1 It is a schematic structural view of the present invention, as shown in the figure, the construction project pre-buried exposed steel bar 5 anti-rust device in the present embodiment, comprises anti-rust cover 4, sealing device 2 and air extraction hole, and one end of anti-rust cover 4 is provided with spout And through the pipe mouth is set on the outer wall of the exposed steel bar 5, the air outlet 9 is located on the side wall of the anti-rust cover 4 and only allows the gas to flow out of the anti-rust cover 4 through the air outlet 9, the sealing device 2 is an elastic pipe with openings at both ends and the Both ends of the sealing device 2 are respectively set on the outer wall of the anti-rust sleeve 4 and the exposed steel bar 5 to form a sealed contact surface.

[0021] In this embodiment, the anti-rust sleeve 4 includes a pipe body section 3 and a nozzle section 6 integrally formed with the pipe body section 3 and inserted into the sealing device 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com