Water pump cavitation testing method and device

A cavitation test and water pump technology, applied in pump control, non-variable pumps, machines/engines, etc., can solve the problems of low test accuracy, long test period, and cumbersome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

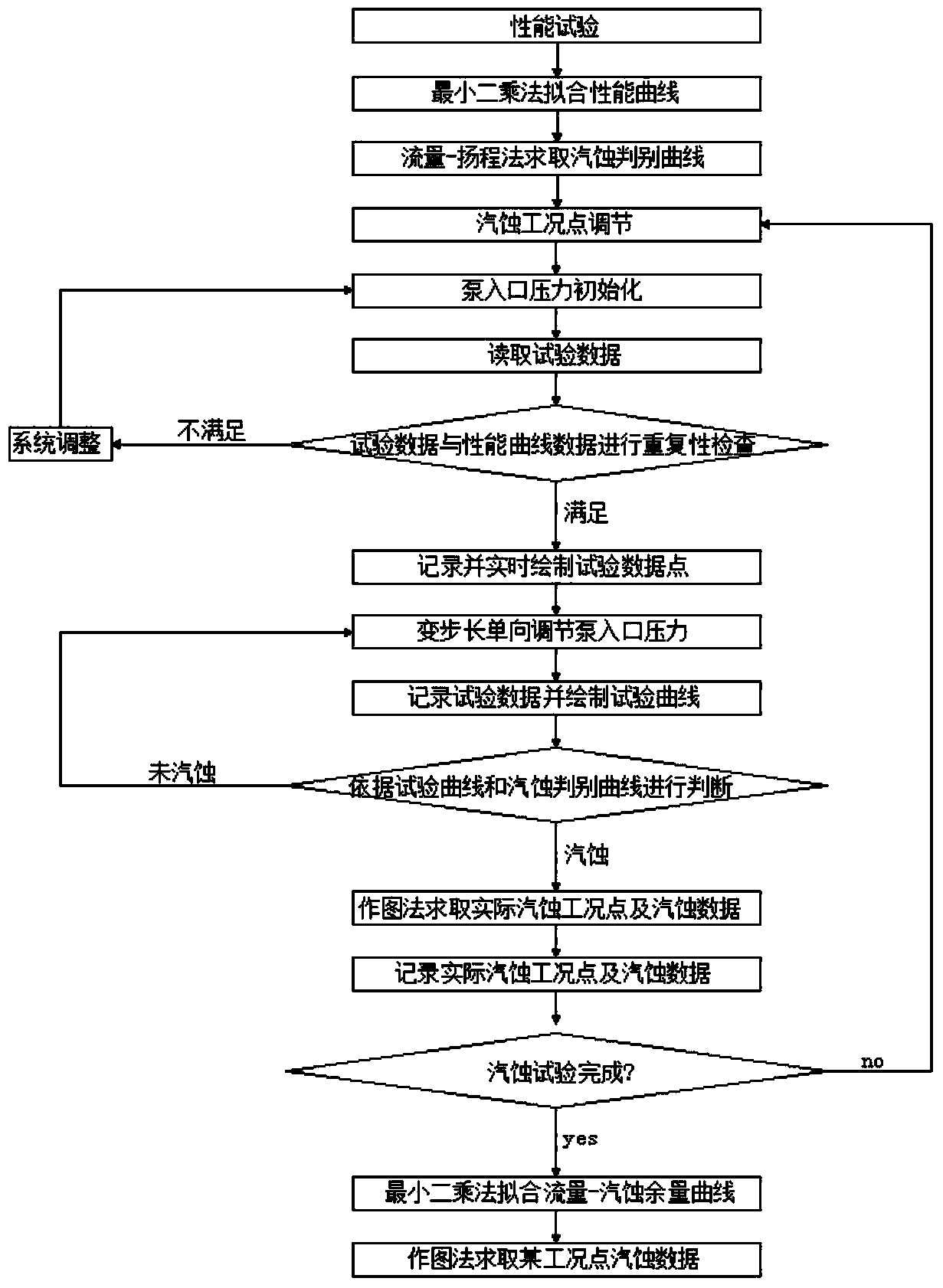

[0041] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

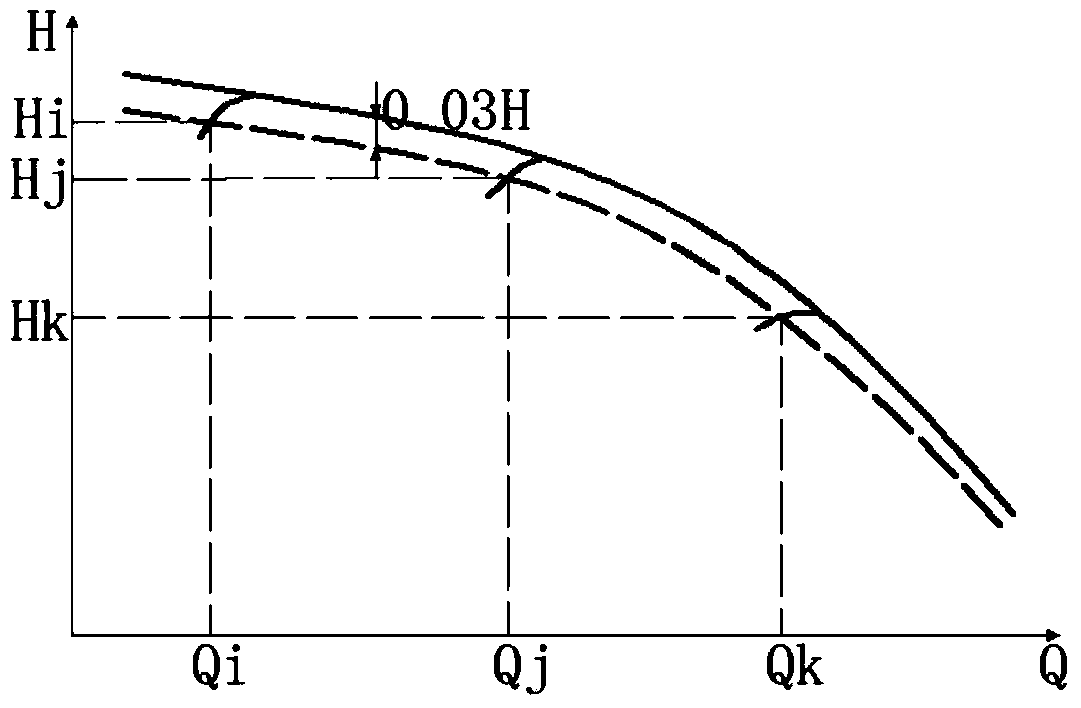

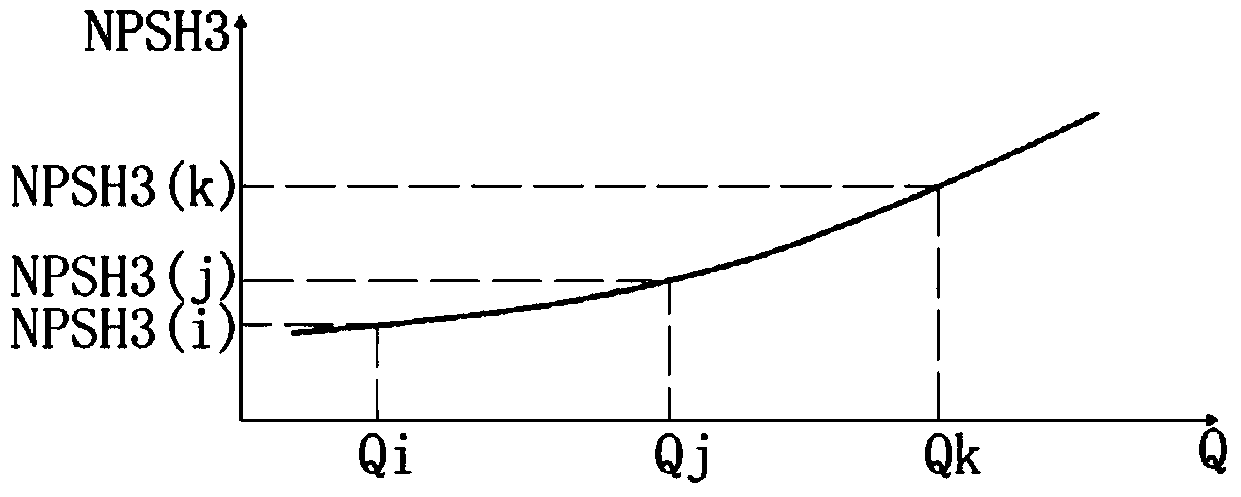

[0042] The NPSH of the pump (NPSHr) indicates the pressure drop during the liquid flow between the pump inlet and the lowest pressure point on the back of the impeller, that is, in order to ensure that the pump does not suffer from cavitation, it is required that the unit weight of the liquid at the pump inlet must have more than the working pressure. The surplus capacity of the vaporization pressure of the liquid at the temperature; the NPSH (NPSHa) of the device is provided by the suction piping system, which means that the unit weight of the liquid at the inlet of the pump actually has a surplus capacity exceeding the vaporization pressure of the liquid at the working temperature . During the actual operation of the pump, when NPSHa≤NPSHr, the pump will experience cavitation. Usually, the state when NPSHa=NPSHr is established is regarded as the cri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com