Chain guide

A chain and guide technology, applied in belts/chains/gears, mechanical equipment, transmissions, etc., can solve problems such as breakage, increased manufacturing time, material waste, etc., to reduce occupied space, simplify manufacturing processes, and reduce manufacturing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

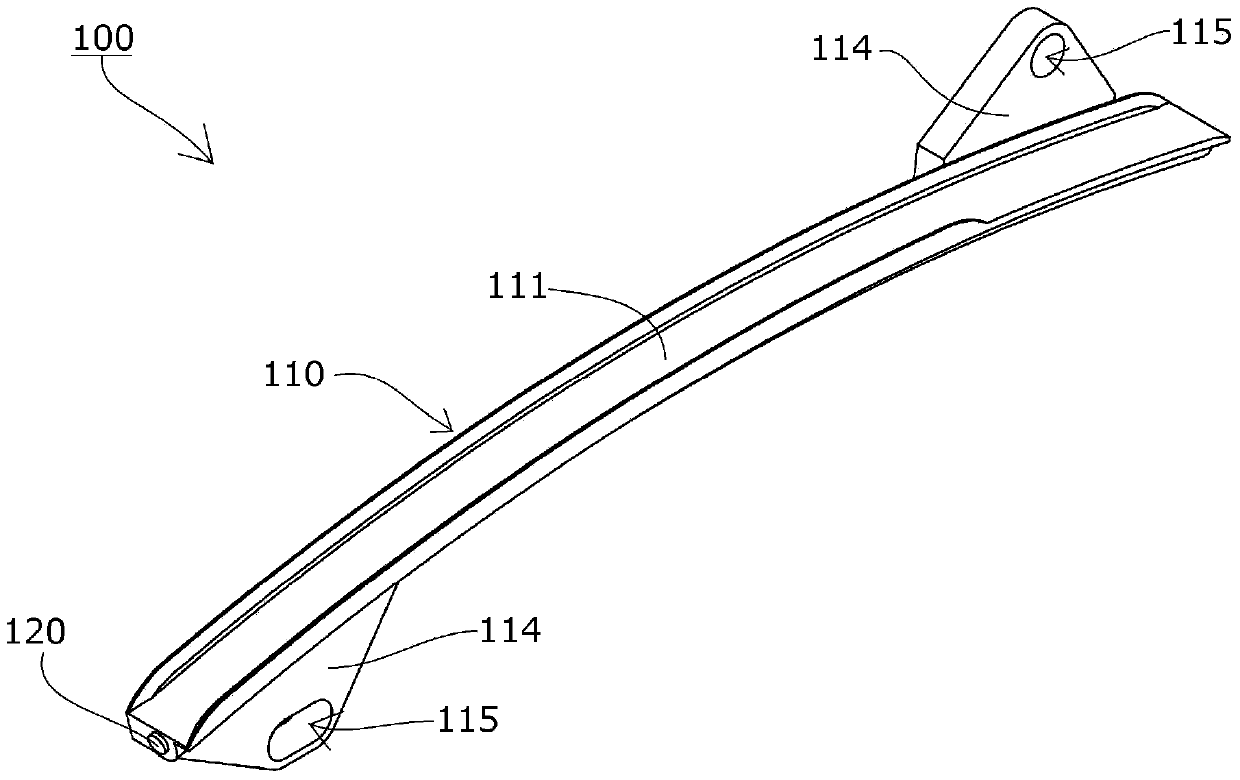

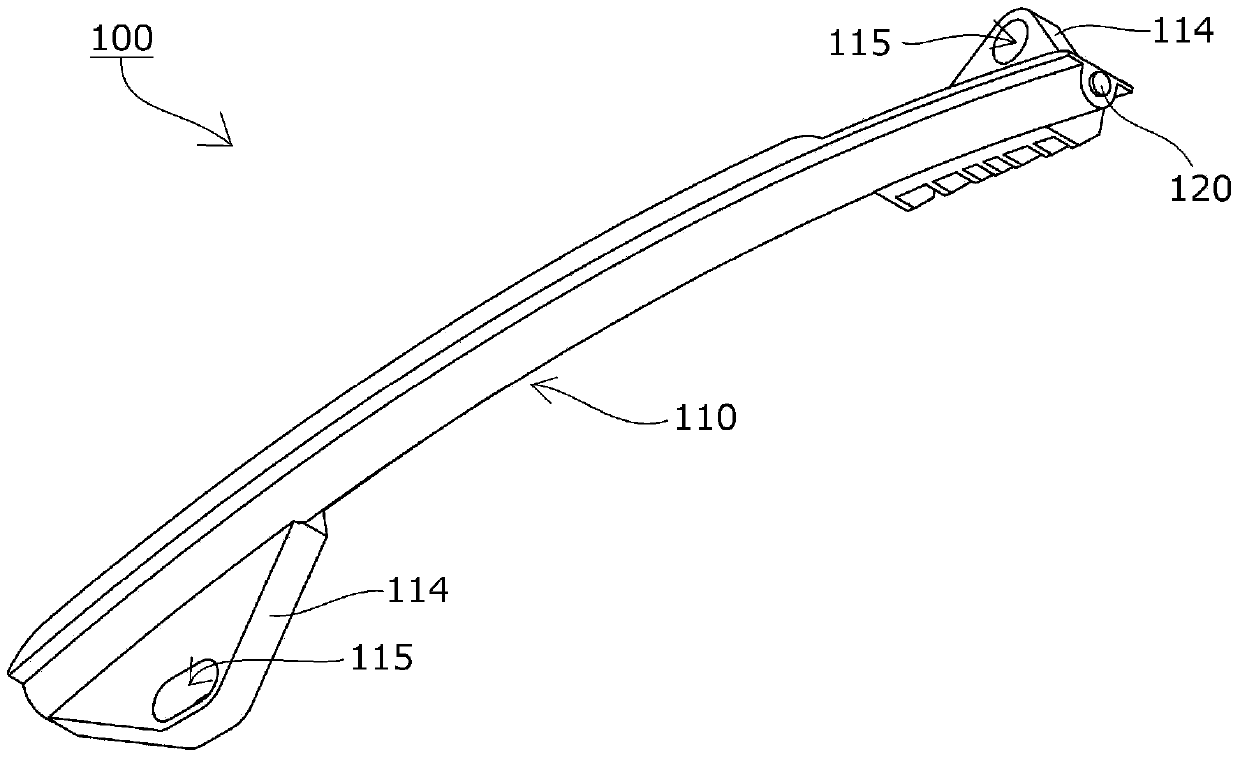

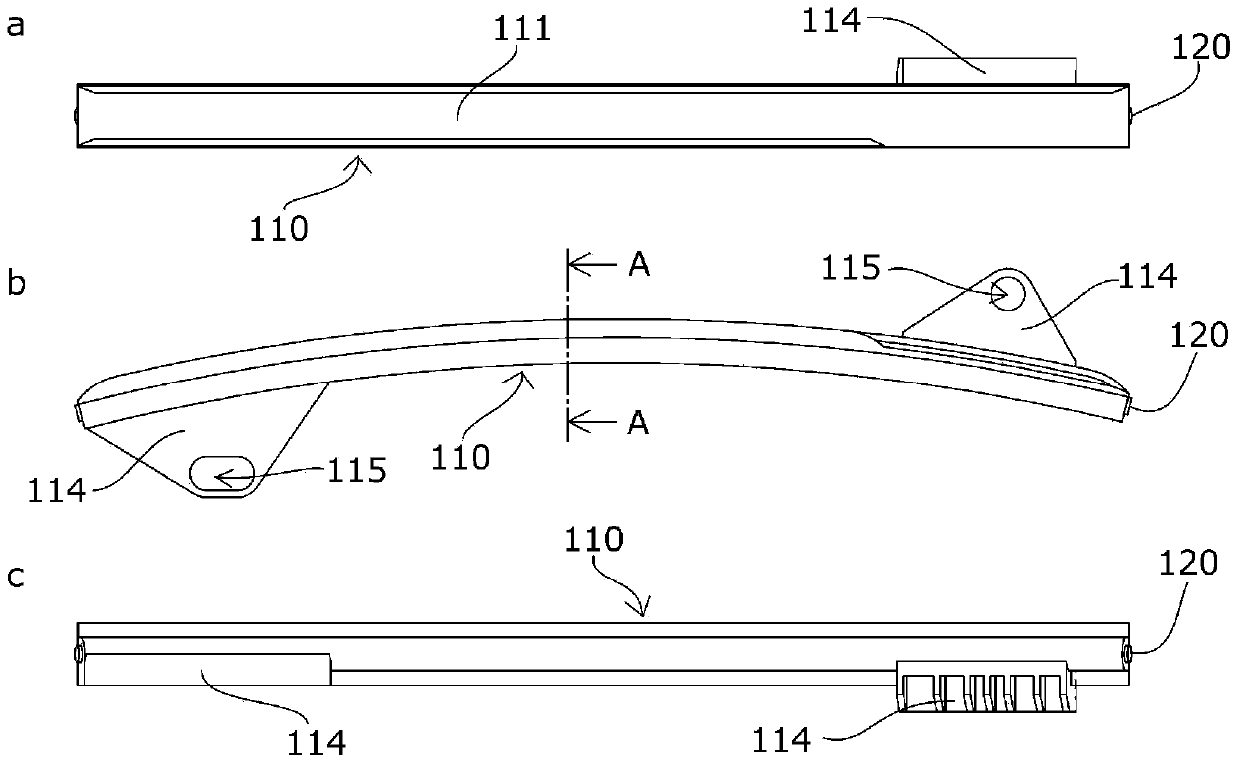

[0067] The chain guide 100 (fixed guide) according to the first embodiment of the present invention will be described with reference to the drawings.

[0068] The chain guide 100 is a chain guide suitable for the aforementioned known timing systems, such as Figure 1 to Figure 4 As shown, there are: a guide block 110, which slides and guides the moving chain; and a base member 120, which reinforces the guide block 110 along the chain movement direction to improve strength, rigidity, and durability.

[0069] The base member 120 is formed of a metal rod extending in the chain movement direction, and is formed, for example, by drawing a steel material and cutting it to an appropriate length.

[0070] In addition, the base member 120 has a prescribed curved shape along the chain moving direction.

[0071] The guide block 110 has a motion guide portion 111 extending in the chain motion direction, is formed of a synthetic resin material, and is integrally molded with the base membe...

Embodiment 2

[0086] A chain guide 200 (fixed guide) according to a second embodiment of the present invention will be described with reference to the drawings.

[0087] The chain guide 200 is a chain guide suitable for the aforementioned known timing systems, such as Figure 7 to Figure 10 As shown, it has: a guide block 210, which slides and guides the moving chain; and a base member 220, which reinforces the guide block 210 along the chain movement direction to improve strength, rigidity, and durability.

[0088] The guide block 210 has a movement guide portion 211 extending in the chain movement direction, is formed of a synthetic resin material, and is integrally formed by, for example, injection molding with the middle portion of the base member 220 inserted therein.

[0089] The base member 220 is formed of a metal rod extending in the chain movement direction, and is formed, for example, by drawing a steel material and cutting it to an appropriate length.

[0090] Both end portions...

Embodiment 3

[0110] A chain guide 300 (swing guide) according to a third embodiment of the present invention will be described with reference to the drawings.

[0111] The chain guide 300 is a chain guide suitable for the aforementioned known timing systems, such as Figure 15 to Figure 18 As shown, it is equipped with: a guide block 310, which swings around the mounting hole 315, and slides and guides the moving chain; durability.

[0112] The base member 320 is formed of a metal rod extending in the direction in which the chain moves, and is formed, for example, by drawing a steel material and cutting it to an appropriate length.

[0113] In addition, the base member 320 has a prescribed curved shape along the moving direction of the chain.

[0114] The guide block 310 is formed of a synthetic resin material, has a motion guide portion 311 extending in the direction of chain motion, and has a longitudinal wall portion 316 on the opposite side of the chain motion of the motion guide por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com