Belt pulley

A technology of pulleys and hubs, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve problems such as small torque, inconvenient processing, and weak flange connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

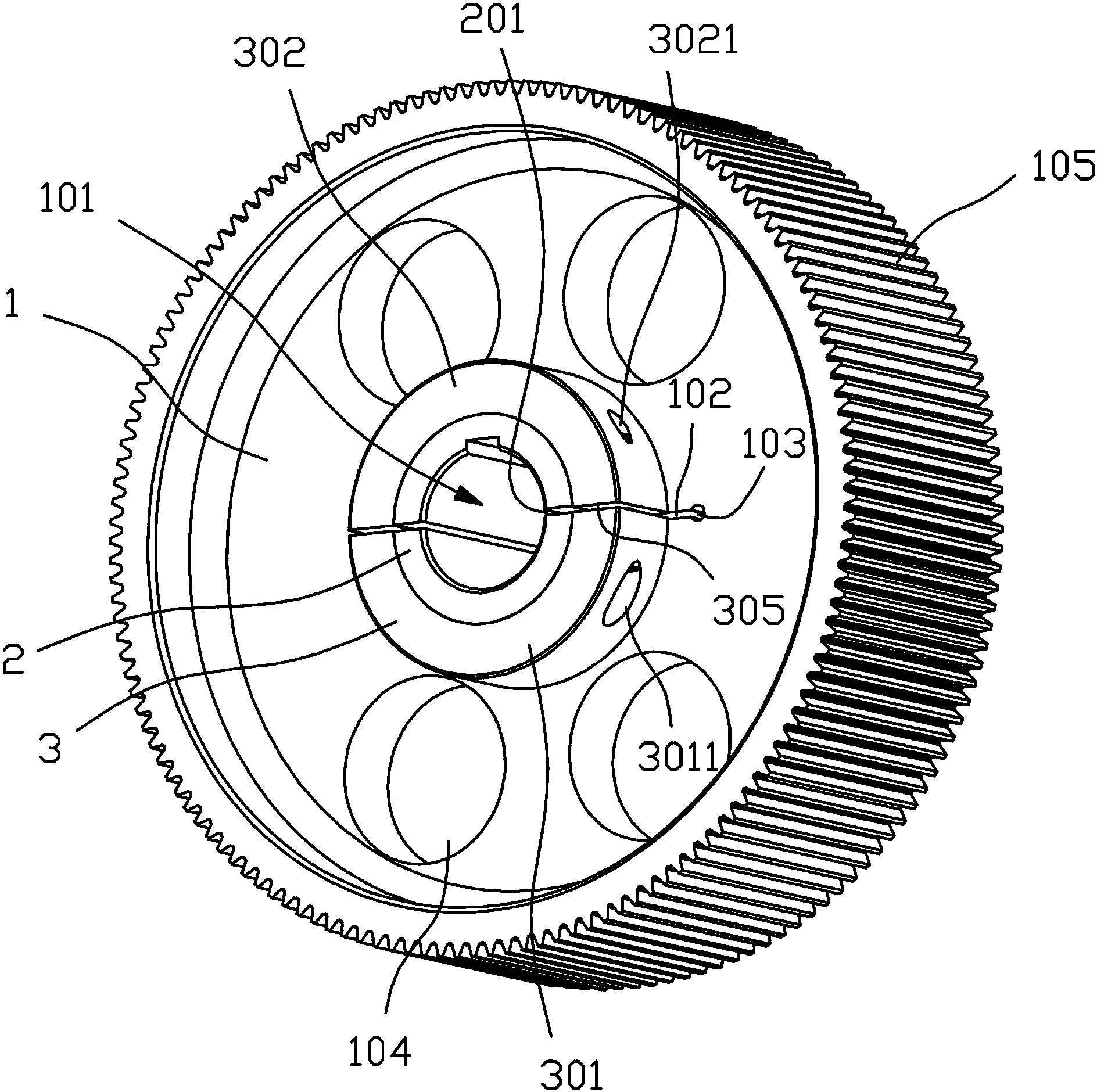

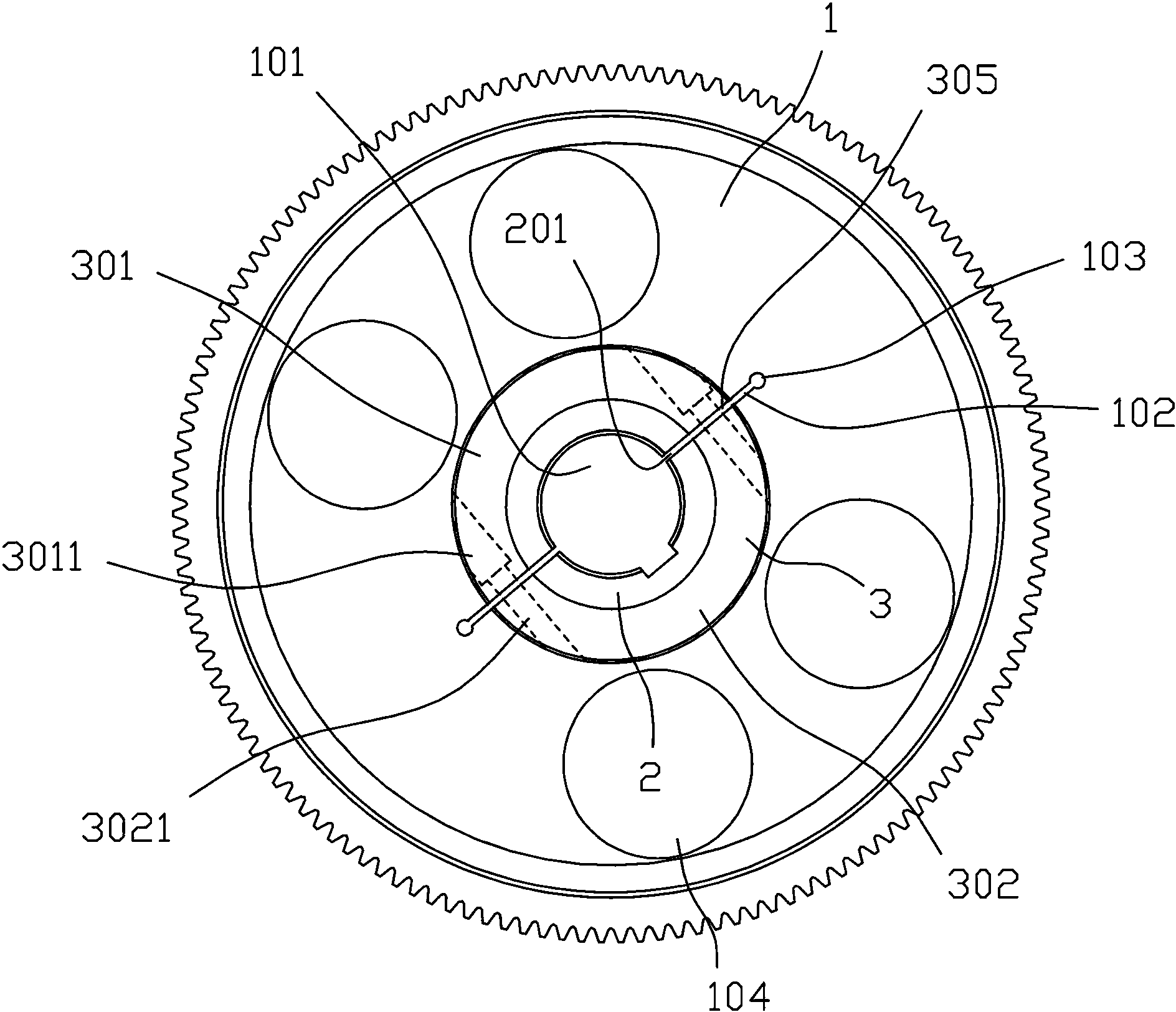

[0037] refer to figure 1 , figure 2 , image 3 , the outer wall of the first annular fastening assembly 2 is a cylindrical surface, the inner wall of the second annular fastening assembly 3 is a cylindrical surface, and the second annular fastening assembly 3 includes a first half ring 301 and a first half ring 301 with opposite ends. The second half-ring 302, a gap 305 is arranged between the two ends of the first half-ring 301 and the second half-ring 302, the gap 305 between the two ends of the first half-ring 301 and the second half-ring 302 and the notch 201 in the same radial direction, both ends of the first half-ring 301 are respectively provided with radially arranged first stepped bolt holes 3011, and both ends of the second half-ring 302 are respectively provided with radially arranged first screw holes 3021 The first stepped bolt hole 3011 and the first screw hole 3021 are set on the coaxial line corresponding to each other, and a first bolt 303 is set in the co...

Embodiment 2

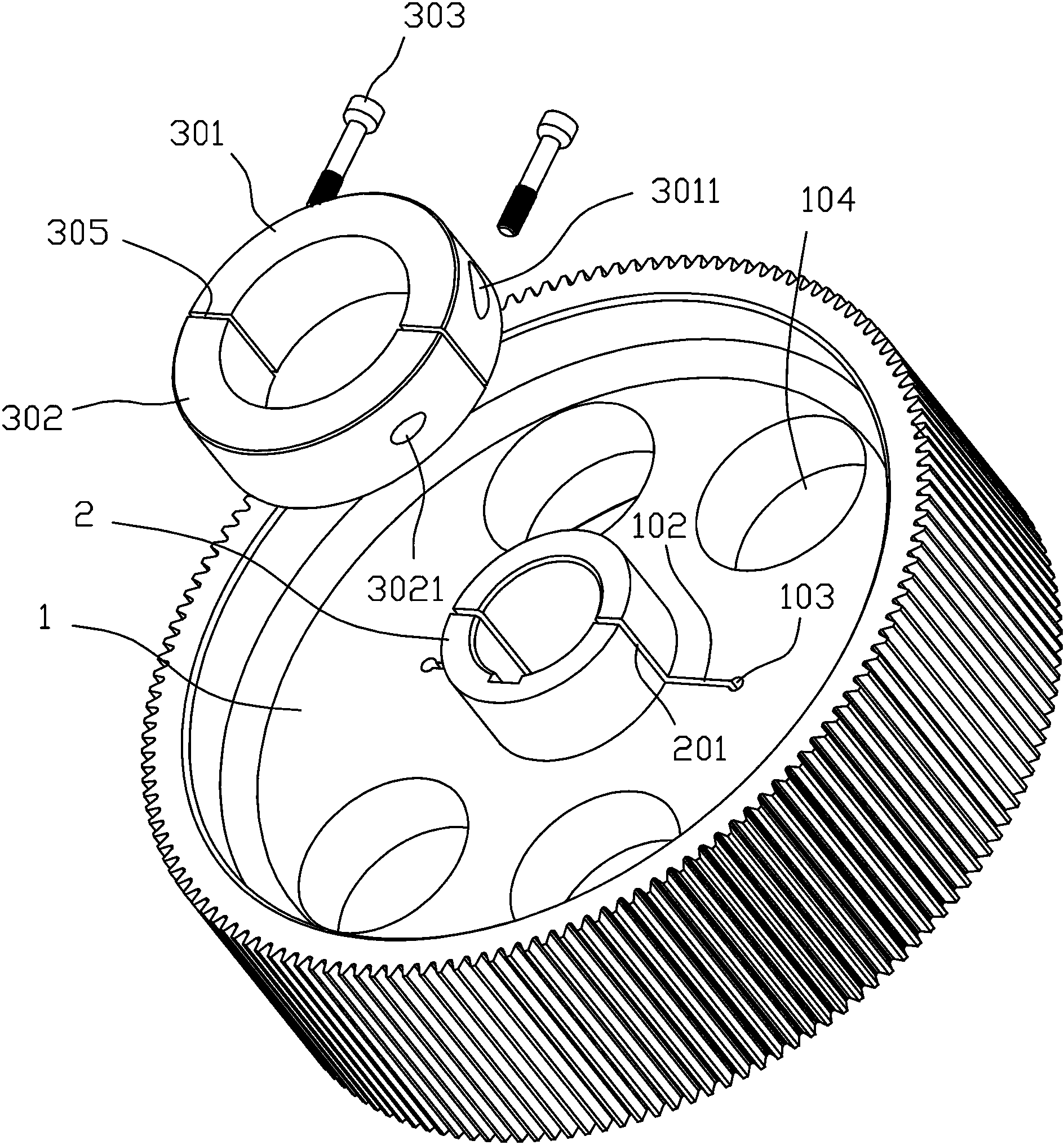

[0039] refer to Figure 4 , Figure 5 , Image 6 , the outer wall of the first annular fastening assembly 2 is a circular table surface, the outer diameter of the first annular fastening assembly 2 gradually increases from the end away from the hub 1 to the end connected to the hub 1, the second annular fastening assembly 3 The inner wall of the inner wall is a circular table surface, and the inner diameter of the second annular fastening component 3 gradually increases from the end far away from the hub 1 to the end close to the hub 1. The hub 1 is axially penetrated and provided with several second screw rods distributed circumferentially around the shaft hole 101. Holes 3022, the second half-ring 302 is axially provided with several second stepped bolt holes 3012 distributed in the circumferential direction, the second stepped bolt holes 3012 and the second screw holes 3022 are arranged on the same axis correspondingly, corresponding A second bolt 304 is disposed in the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com