A high-precision non-contact workpiece inner diameter measuring device and method

A measuring device and non-contact technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems that the laser ranging sensor cannot be placed in the inner bore, and the inner bore of the workpiece cannot be accurately measured, so as to achieve fast measurement speed, The effect of small measurement point and high directivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

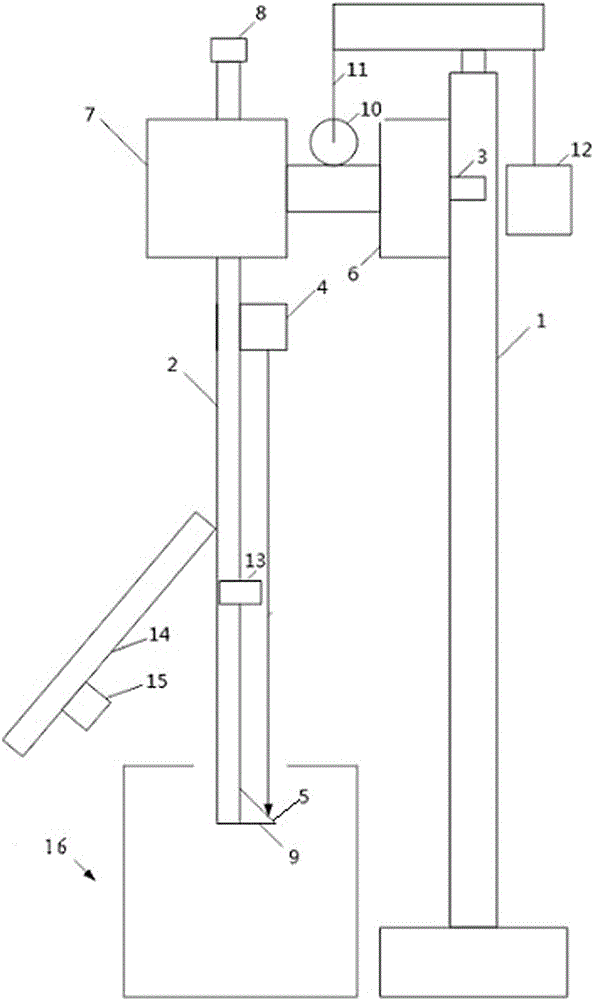

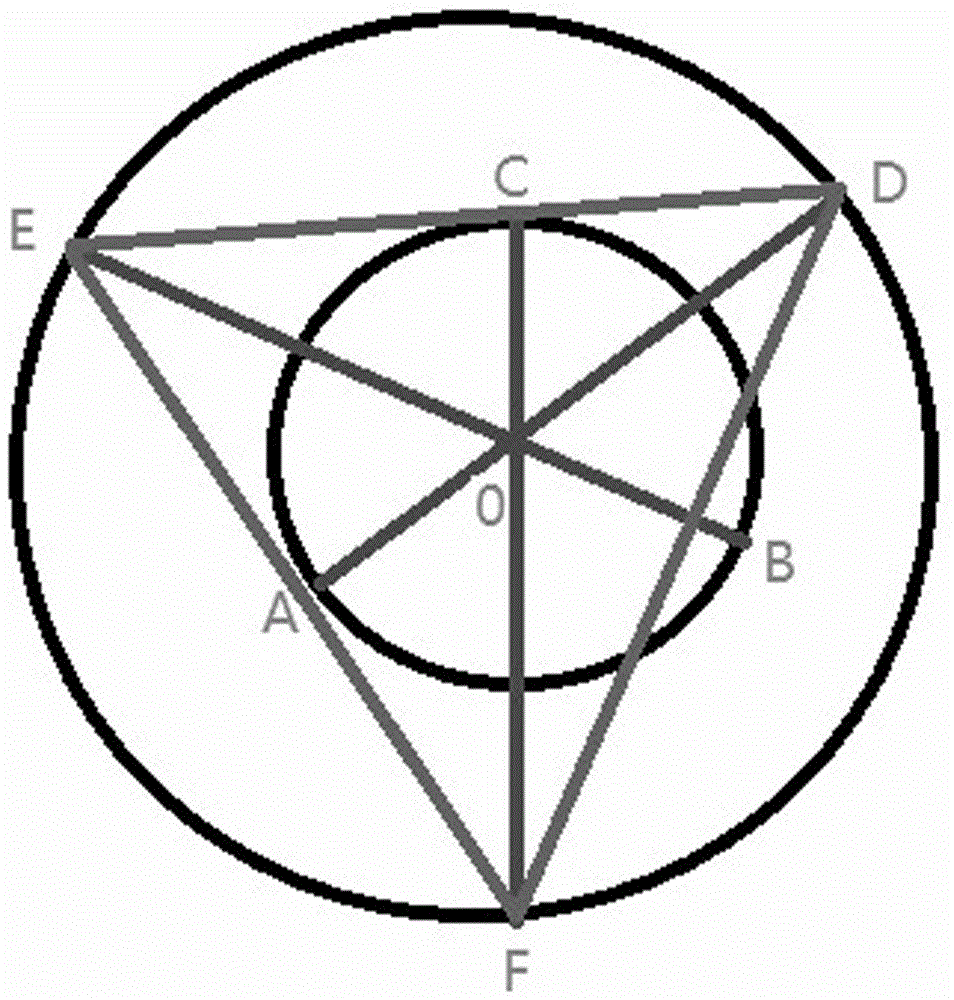

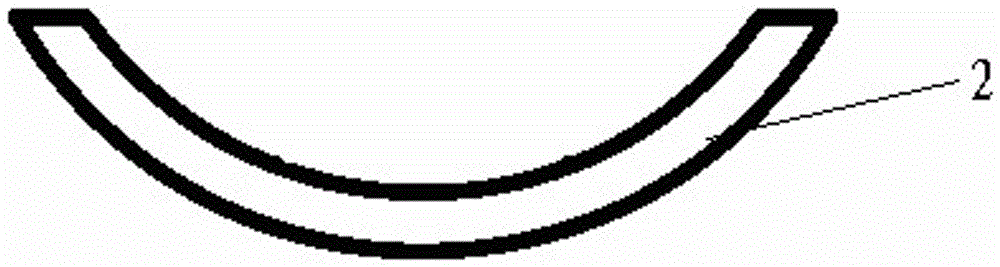

[0023] A high-precision non-contact workpiece inner diameter measuring device, comprising a fixed bracket 1, a first measuring rod 2, a second measuring rod 14, a first driving mechanism 3, a second driving mechanism 8, a first laser distance measuring sensor 4, a second A laser distance measuring sensor 13 , a third laser distance measuring sensor 15 , a rotating frame 7 and a reflector 5 . The fixed bracket 1 is provided with a sliding track, the cross-section of the first measuring rod 2 is arc-shaped, the first measuring rod 2 is placed in the rotating frame 7, and the outer wall of the rotating frame 7 is fixedly connected with a slider 6, and the sliding The block 6 is connected with the sliding track set by the fixed bracket 1, and a suspension ring 10 is arranged on the slider 6, and the suspension ring 10 is connected with the counterweight mechanism 12 through a hinge 11. The slider 6 is located at the first side of the fixed bracket 1, and the counterweight mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com