Measuring method for non-gate-control liquid turbidity measuring device based on time correlation single photon counting

A single photon counting, time-dependent technology, applied in the measurement of scattering characteristics, etc., to achieve the effect of fast current growth, online real-time measurement, and improved measurement accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

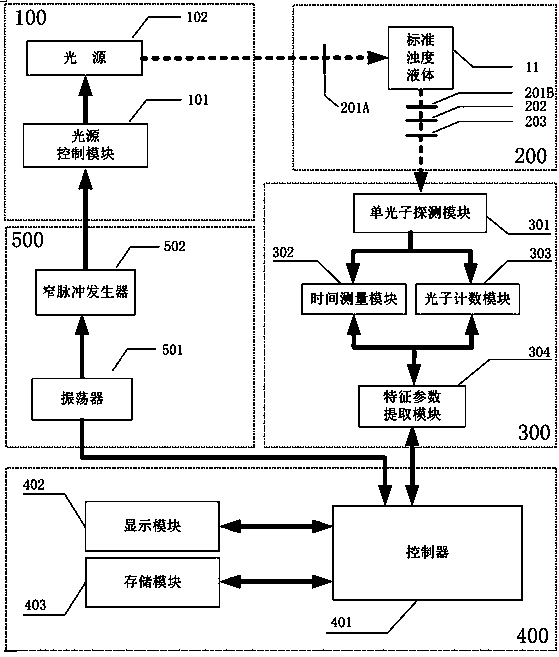

[0050] Such as figure 1 The schematic diagram of a non-gated liquid turbidity measurement device based on time-correlated single photon counting is shown, which mainly includes a light source module 100, an optical path transmission module 200, a photoelectric conversion and signal processing module 300, a control module 400, a signal generation module 500 and Standard turbidity liquid 11; the light source module 100 includes a light source control module 101, a light source 102; the optical path transmission module 200 includes a first lens 201A, a second lens 201B, a bandpass filter 202, and an aperture 203; the The photoelectric conversion and signal processing module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com