Bucky electronic tag and manufacturing method thereof

An electronic label and cloth-based technology, which is applied to record carriers, instruments, computer parts, etc. used in machines, can solve the problems that cannot meet the production characteristics and use characteristics of clothing cloth-based materials, cannot be rubbed, and has poor acid and alkali resistance. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 The manufacturing process of the cloth-based electronic tag is as follows:

[0045] 1) Manufacture plastic-encapsulated RFID unit 2

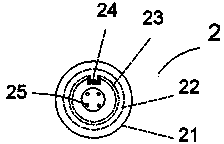

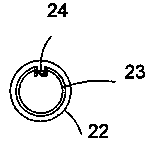

[0046] The traditional process can be used to manufacture the RFID unit first, and the silver paddle is used to print the circular radiation antenna 23 on the PET polyester film, and the chip is mounted; or the aluminum etching forming process can be used, the chip is flip-chip mounted, and after curing, die-cut ring.

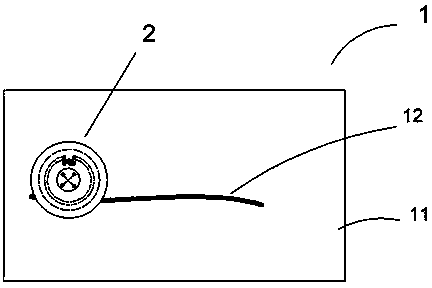

[0047] Then, the button-shaped plastic housing 21 is molded by an insert injection molding process to encapsulate the RFID unit at the same time, forming a button-shaped plastic-encapsulated RFID unit 2 at one time (see figure 2 ). It can also be implemented by embedding the RFID unit in a button of suitable size.

[0048] 2) Manufacturing the bucky coupling antenna 1

[0049] Use a computerized rusting machine on the cloth base material, use the metal wire covered polyester yarn or metal wire as the shut...

Embodiment 2

[0056]Embodiment 2 Bucky electronic tags such as Figure 6 As shown, the tag includes a bucky coupling antenna 1 and a plastic-encapsulated RFID unit 2 .

[0057] Such as Figure 7 , 8 The plastic-encapsulated RFID unit 2 includes a plastic housing 21 and an RFID unit. The plastic housing 21 is in the shape of a square label (similar to a hang tag for traditional clothing). The RFID unit consists of a base film 22, a radiation antenna 23 arranged on the base film 22, and a radio frequency IC24 constitutes. The radiating antenna 23 has a square shape as a whole, and the lower side is bent inward to form an inner concave part of the middle opening. The radio frequency IC 24 is connected to the opening, and the RFID unit is plastic-sealed in the plastic casing 21 .

[0058] Such as Figure 9 , the cloth-based coupling antenna 1 includes a cloth base sheet 11 and a coupling antenna 12 formed on the cloth base sheet 11 with metal yarn as a shuttle, weaving or sewing; the coupli...

Embodiment 3

[0060] Embodiment 3 Bucky electronic tags such as Figure 10 As shown, the tag includes a bucky coupling antenna 1 and a plastic-encapsulated RFID unit 2 .

[0061] Such as Figure 11 , 12 The plastic-encapsulated RFID unit 2 includes a plastic housing 21 and an RFID unit. The plastic housing 21 is in the shape of an elliptical label (similar to an elliptical tag for traditional clothing), and the RFID unit consists of a base film 22, a radiation antenna 23 disposed on the base film 22, and The radio frequency IC24 is formed; the radiation antenna 23 has a rectangular opening (or folded vibrator), and the radio frequency IC24 is connected to the opening; the RFID unit is plastic-sealed in the plastic casing 21 .

[0062] Such as Figure 13 , the cloth-based coupling antenna 1 includes a cloth-based sheet 11 and a coupling antenna 12 formed on the cloth-based sheet 11 with wire yarn as a shuttle thread, woven or sewn; the coupled antenna 12 includes a folded vibrator 121 wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com