Easy-to-start motor and base thereof

A motor and base technology, applied in the field of motors and their bases, can solve the problems of ineffectiveness of blocking electromagnetic, weak axial thickness, easy loss, etc., and achieves the effect of improving bonding stability and improving operation stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments of the present invention will be described in detail below together with the accompanying drawings.

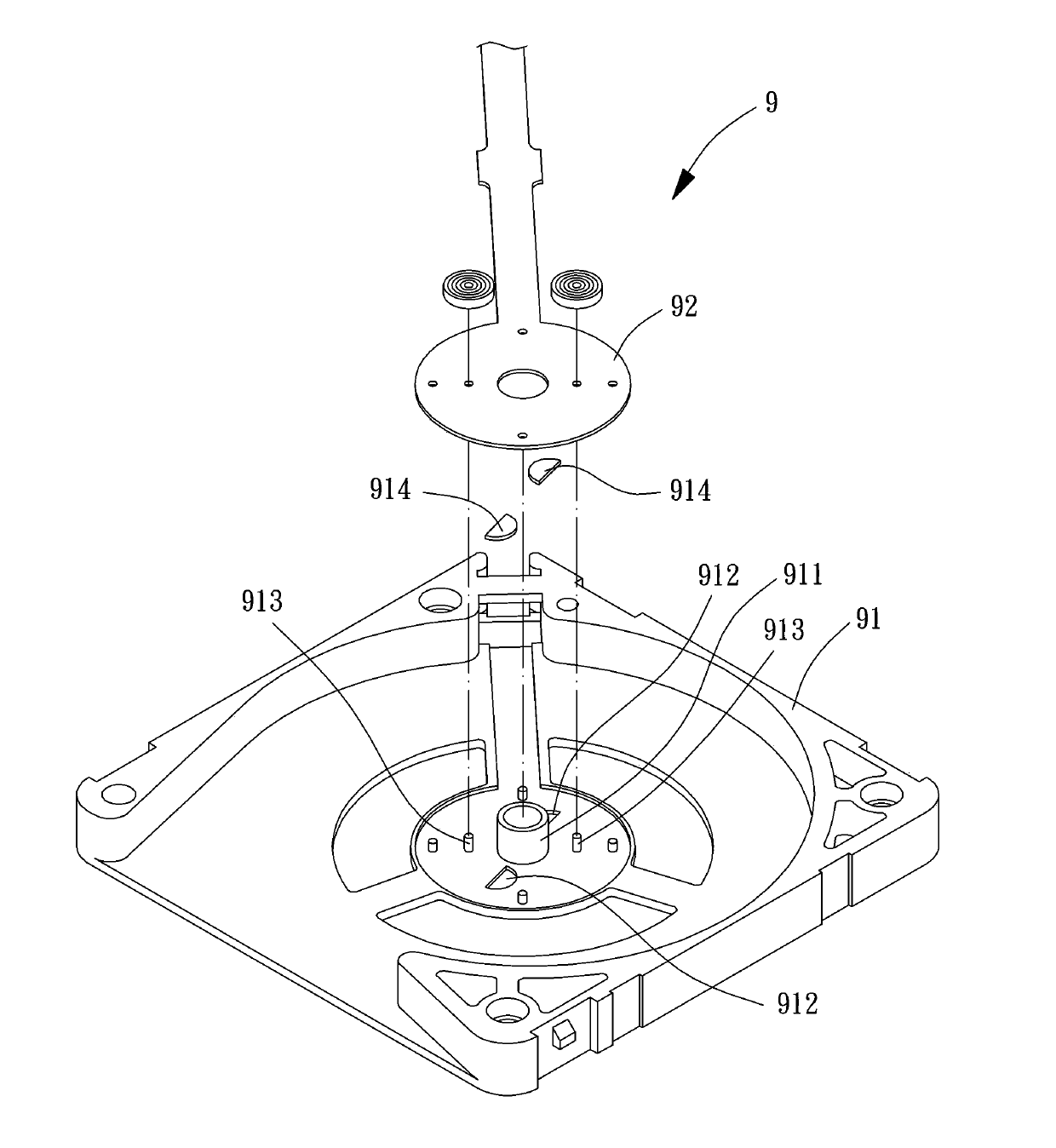

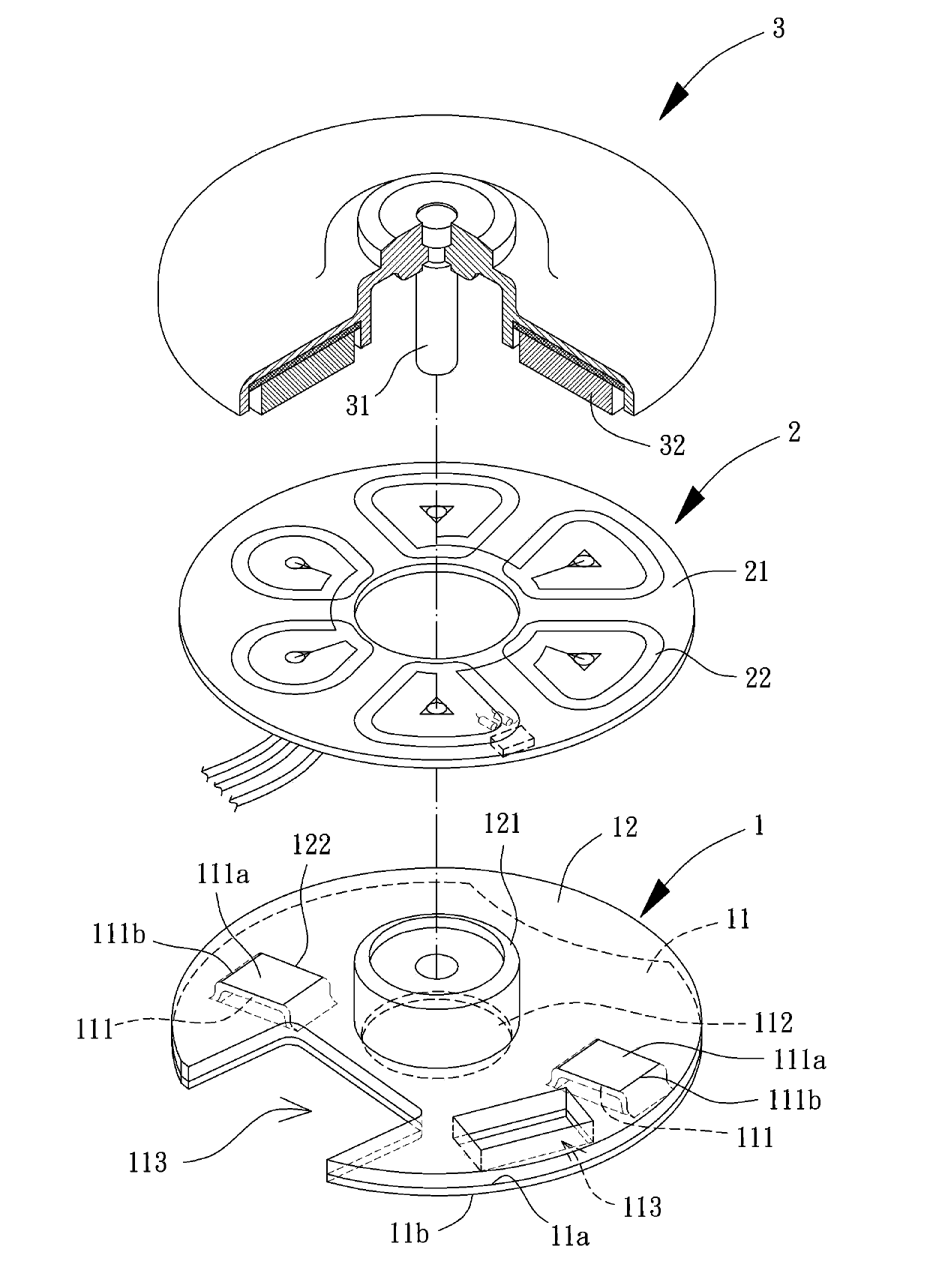

[0044] Please refer to figure 2 As shown, the easy-to-start motor of the preferred embodiment of the present invention includes at least a base 1 , a stator 2 and a rotor 3 . The base 1 can be combined with the stator 2 , the rotor 3 is rotatably combined with the base 1 , and the stator 2 is used to drive the rotor 3 to rotate.

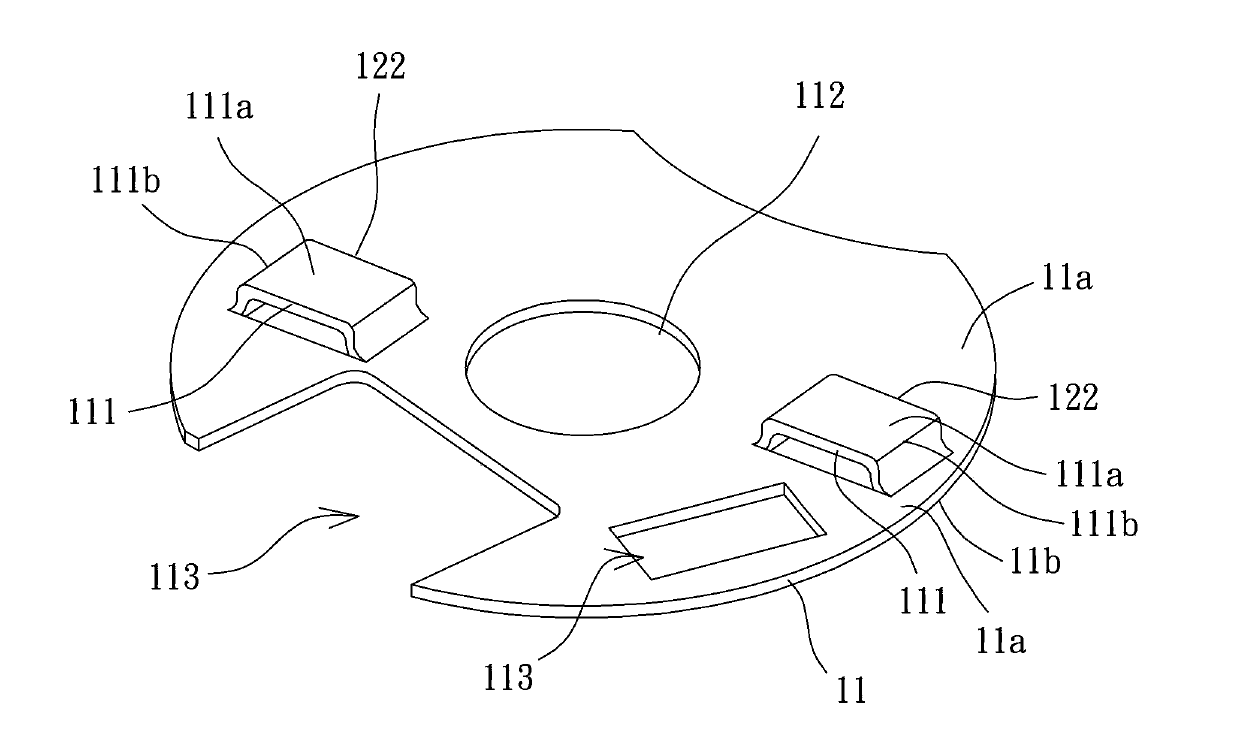

[0045] The base 1 includes a metal sensing element 11 and a plastic element 12 . Please refer to Figures 2 and 3 at the same time, the metal induction element 11 is provided with at least one magnetic attraction portion 111, the number of the at least one magnetic attraction portion 111 can be one or several, the shape and quantity of the magnetic attraction portion 111 The best choice is to provide a per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com