A Fast Precharge Circuit for Modular Multilevel Converter

A modular multi-level, pre-charging circuit technology, applied in the direction of electrical components, output power conversion devices, etc., can solve the impact of equipment safety and reliability, increase the power loss of current-limiting resistors, and the long time required for pre-charging and other issues, to achieve the effect of improving power utilization, improving work efficiency, and reducing charging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

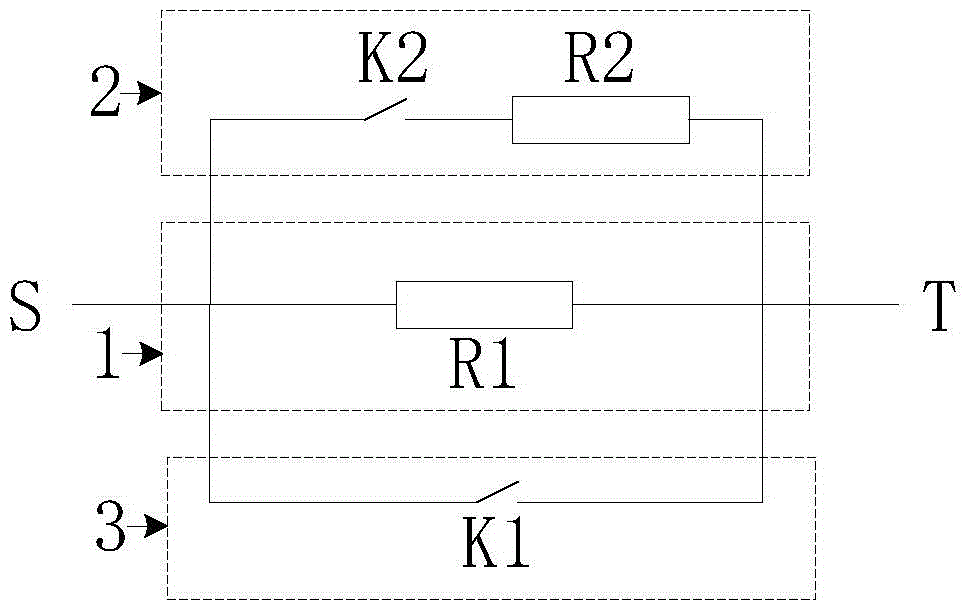

[0023] The fast pre-charging circuit of the modular multi-level converter consists of three parts, including the main current-limiting charging part, the accelerated charging part and the normal operation part.

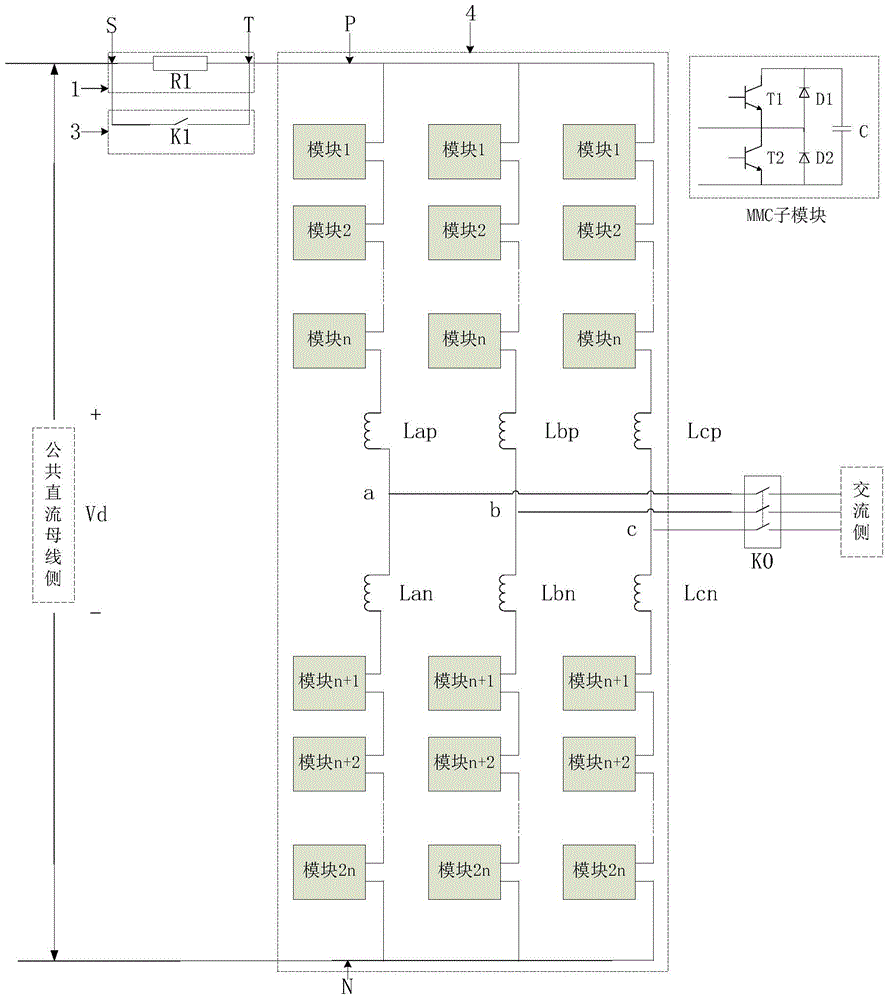

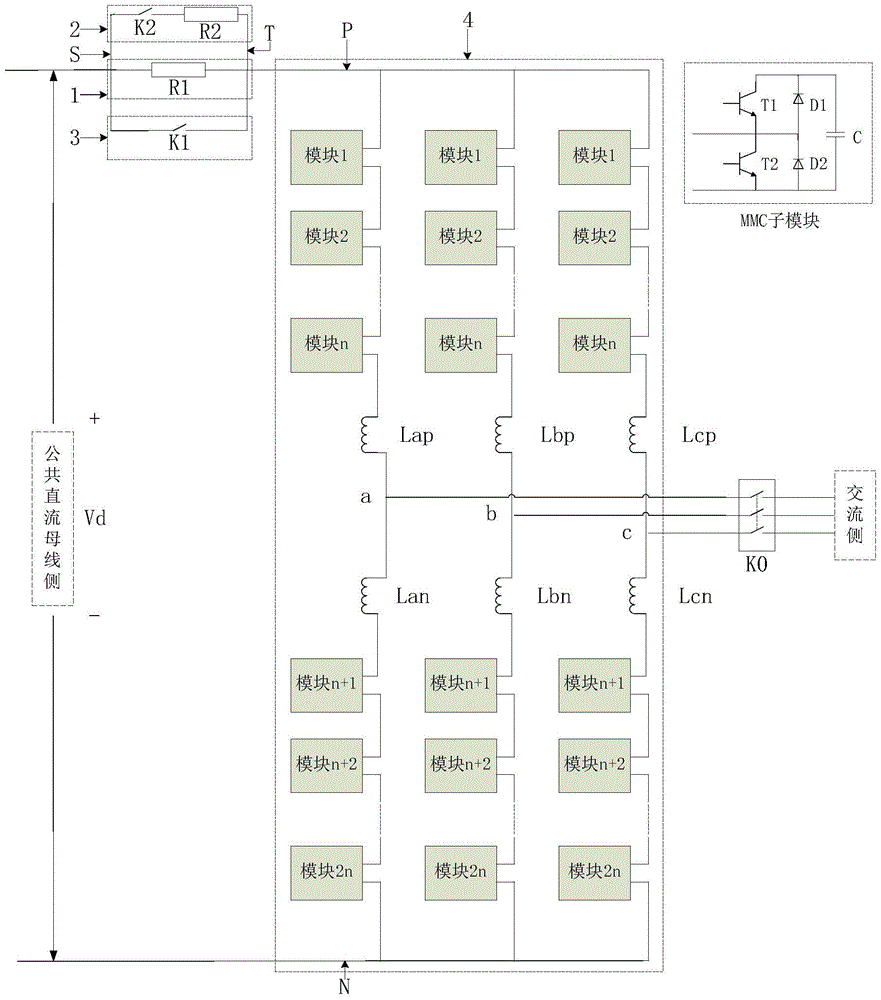

[0024] The charging power source of the fast precharging circuit of the modular multilevel converter can be charged by a DC power supply or an AC power supply. When charging with a DC power source, such as image 3 , the common terminals S and T of the fast precharging circuit are respectively connected to the positive pole of the DC power supply and the common terminal P of the upper bridge arm of the modular multilevel converter. When charging with an AC power source, such as Figure 4 , the fast precharging circuit uses a three-phase AC structure, and is respectively connected to the AC power supply and the common terminals a, b, and c of each phase bridge arm of the modular multilevel converter. The fast pre-charging circuit of the modular multi-level converter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com