Reinforced fiberglass gypsum board automatic production line

An automatic production line and glass fiber technology, applied in ceramic molding workshops, auxiliary molding equipment, supply devices, etc., can solve problems such as poor product flatness and gloss, low degree of mechanization, and inability to produce gypsum boards, and meet cutting requirements. As well as the need for the intensity of transshipment, the competitiveness of the large market, and the effect of synchronization of transmission distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

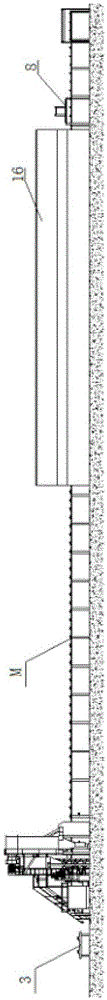

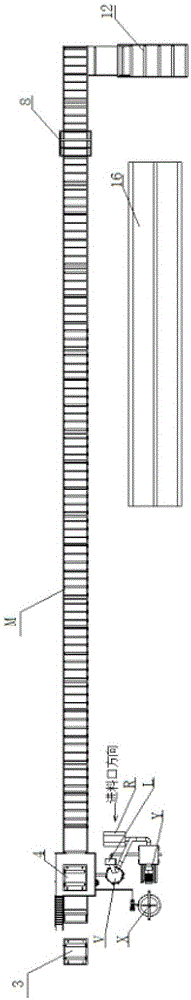

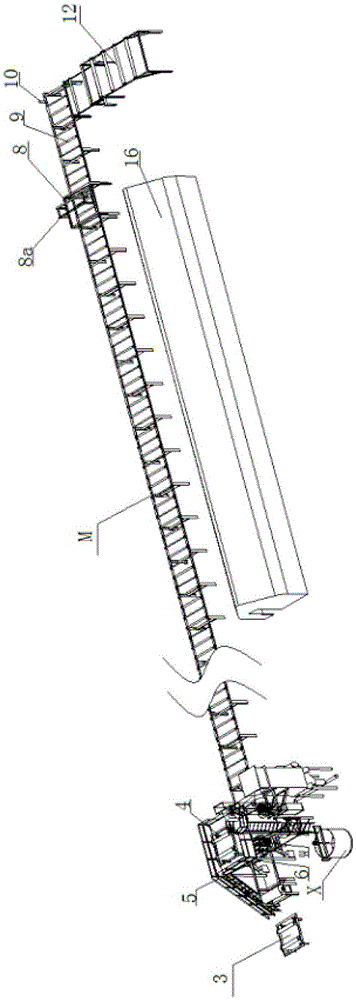

[0047] see Figure 1~3 as well as Figure 5-8 , an automatic production line for reinforced glass fiber gypsum board, which has: a gypsum board extrusion molding mechanism composed of an upper and a lower two-layer conveying system. On the premise that the linear speed of the conveyor belt is equal, the reinforced fiber gypsum board with double-layer grid cloth structure is fed into the extrusion molding mechanism to achieve it. The lower surface of the upper conveyor belt and the upper surface of the lower conveyor belt are parallel to each other and form extrusion molding. It can be understood that the gap K is regarded as a forming space, and the lower surface of the upper conveyor belt and the upper surface of the lower conveyor belt are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com