Composite thermal expansion material tube and manufacturing method thereof

A manufacturing method and material tube technology, which can be applied to table utensils, table utensils, home utensils, etc., can solve problems such as inability to judge the temperature of liquids, and achieve the effect of preventing hot drinks from being consumed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

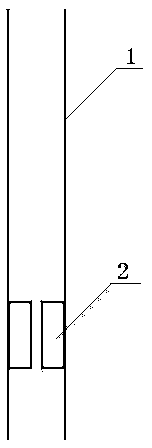

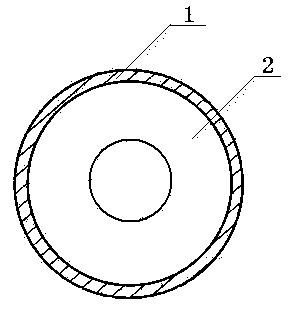

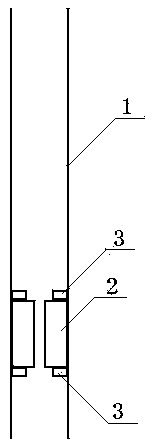

[0023] Below in conjunction with accompanying drawing, the present invention is further described.

[0024] First make a composite material, the steps are:

[0025] Wash the fungus, remove the silt and sawdust at the root, put it in boiling water, cook it, and then dry it. Experiments show that it can be dried or sun-dried. It has been found through experiments that it is better to crush until the particle diameter is between 30 microns and 50 microns. The present invention names this material fungus powder.

[0026] Wash the mushrooms: remove the sediment, cook them in boiling water, and then dry them. Tests show that they can be dried in the sun or in the sun. It has been found through experiments that it is better to crush until the particle diameter is between 30 microns and 50 microns. The present invention names this material mushroom powder.

[0027] Do the same with kelp: wash it, cook it, dry it, and crush it until the particle diameter is 30-50 microns. The pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com