A kind of preparation method of fully biodegradable stone paper

A stone paper, all-biological technology, applied in the field of polymer materials, can solve problems such as environmental pollution and refractory degradation, and achieve the effects of good writing performance, smooth surface and excellent paper performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

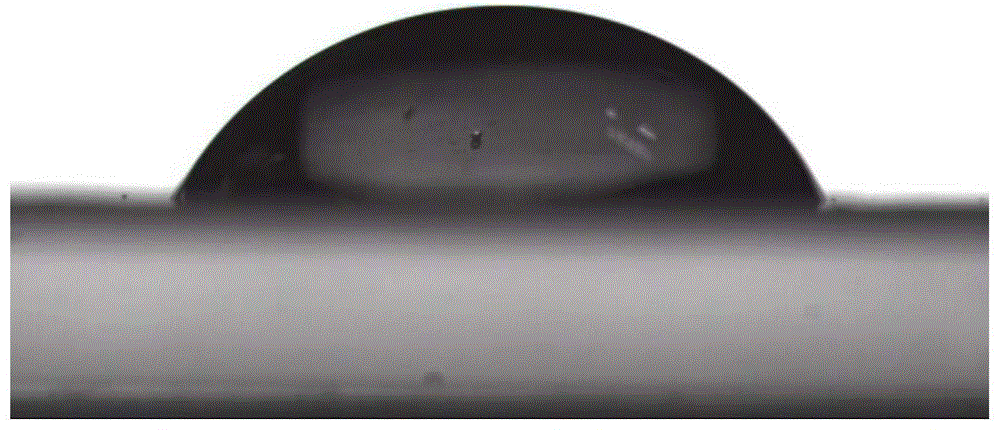

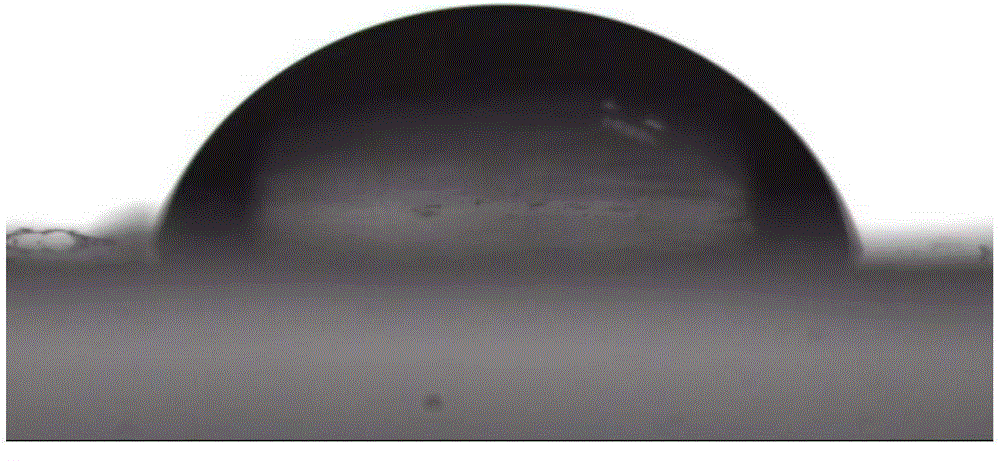

Image

Examples

Embodiment 1

[0024] Weigh each component according to the following mass percentages: 70% of light calcium carbonate with a particle diameter of 100 nanometers, 15% of polybutylene succinate, 3% of vinyl triethoxysilane coupling agent, 5% of titanium dioxide %, compatibilizer (PBS-g-GMA) 4%, polyvinyl alcohol 3%;

[0025] The light calcium carbonate, polybutylene succinate, titanium dioxide, compatibilizer and polyvinyl alcohol are fully dried under vacuum, so that the moisture content thereof is lower than 0.2 wt%.

[0026] The vinyl triethoxysilane coupling agent is fully mixed with the light calcium carbonate, so that the surface of the light calcium carbonate is fully wetted by the coupling agent, and the light calcium carbonate modified by the coupling agent is obtained.

[0027] Add dry polybutylene succinate, titanium dioxide, compatibilizer and polyvinyl alcohol to the light calcium carbonate modified by the coupling agent, and stir at high speed to mix evenly. Then it is extruded...

Embodiment 2

[0030] Weigh each component by the following mass percentages: 35% of light calcium carbonate with a particle diameter of 10 microns, 30% of heavy calcium carbonate with a particle diameter of 10 microns, 22% of polybutylene succinate, vinyl tri(β -Methylethoxy) silane coupling agent 3%, titanium dioxide 4%, lithopone 1%, compatibilizer (PBS-g-GMA) 3%, polyvinyl alcohol 2%;

[0031] And light calcium carbonate, heavy calcium carbonate, polybutylene succinate, titanium dioxide, lithopone, compatibilizer, polyvinyl alcohol are fully dried under vacuum, so that the moisture content thereof is lower than 0.2wt% .

[0032] Fully mix vinyl tris(β-methylethoxy)silane coupling agent with light calcium carbonate and heavy calcium carbonate so that the coupling agent can fully wet the surface of calcium carbonate to obtain coupling agent-modified light Calcium carbonate and ground calcium carbonate mixture.

[0033] Add dry polybutylene succinate, titanium dioxide, lithopone, compatib...

Embodiment 3

[0036] Weigh each component according to the following mass percentages: 40% of light calcium carbonate with a particle diameter of 80 microns, 40% of diatomite with a particle diameter of 80 microns, 12% of polybutylene succinate, γ-propylene methacrylate Ester-based (trimethoxy) silane coupling agent 1%, iron red 4%, compatibilizer (PBS-g-MAH) 1%, polyvinyl alcohol 2%;

[0037] And light calcium carbonate, diatomaceous earth, polybutylene succinate, iron red, compatibilizer and polyvinyl alcohol are fully dried under vacuum, so that the moisture content therein is lower than 0.2wt%.

[0038] Fully mix the γ-propylmethacrylate-based (trimethoxy) silane coupling agent with light calcium carbonate and diatomaceous earth so that the coupling agent fully wets the surface of light calcium carbonate and diatomite to obtain a coupling A mixture of light calcium carbonate and diatomaceous earth modified by a joint agent.

[0039] Add dry polybutylene succinate, iron red, compatibili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com