A kind of ab slub composite yarn and production method thereof

A production method and technology of composite yarn, applied in the direction of yarn, textile and papermaking, can solve the problems of unstable quality of ordinary slub yarn, troublesome weaving, single color of ordinary AB yarn, etc., to achieve rich color changes and improved stability , the effect of broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

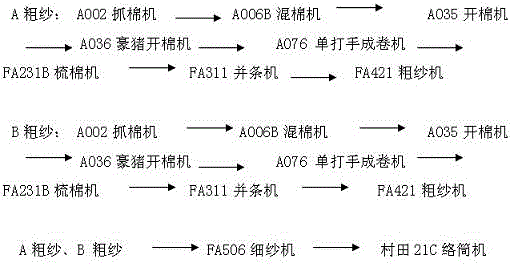

[0030] Embodiment, an AB slub composite yarn, raw material index: A roving: 100% cotton, grade 3.0, length 28.0, micronaire value 4.66, fineness 5413, single fiber breaking strength 32.02, uniformity 81.81, short fiber 11.3 , Moisture regain 6.93, impurity content 1.7; B roving: 100% fine denier polyester, linear density 0.8, dry breaking strength 6.24, dry strength coefficient of variation 8.25, average length 37.0, defect 0, curl 5.1, moisture regain 0.42.

[0031] A roving raw material and B roving raw material respectively go through opening and cleaning, carding, drawing, and roving separately in turn, and after being made into rovings separately, they are fed together on the spinning frame to produce bobbins, and then go through the winder to make a certain package. of bobbins.

[0032] The production method of AB slub composite yarn specifically comprises the steps:

[0033] (1) For A roving:

[0034] Cotton opening and cleaning process: adopt the process of "fine gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com