Finished metal drip line in building construction

A technology for building construction and dripping line, which is applied in construction, building structure, roof drainage, etc., can solve the problems of high technical requirements, consumption of man-hours, easy cracking of the plastering surface, and achieves simple operation process, high precision of finished products, High-quality finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

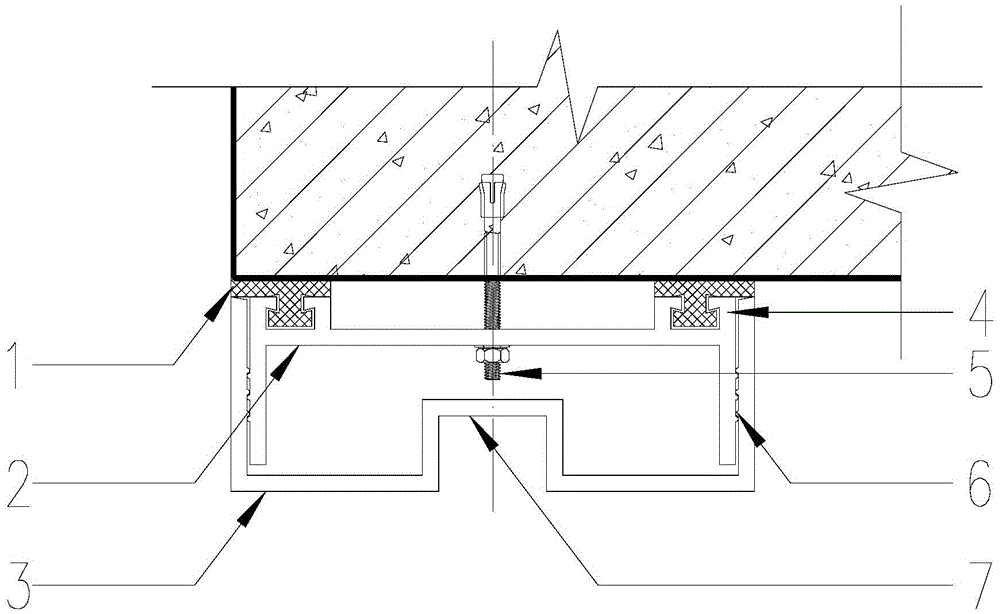

[0015] The finished metal drip line structure in building construction of the present invention is described in conjunction with the accompanying drawings.

[0016] Such as figure 1 As shown, the finished metal drip line in the building construction of the present invention, the drip line structure includes a rubber waterproof strip 1, a drip line inner frame 2, a drip line outer frame 3, and expansion tube screws 5, and the drip line inner frame 2 The top surface is provided with a card slot 4, and the card slot 4 is provided with a rubber waterproof strip 1. The inner skeleton of the drip line 2 is fixed on the installation surface of the finished product during construction by the expansion tube screw 5, and is pressed by tightening the expansion tube screw 5. Tight rubber waterproof strip1.

[0017] The outer side of the wing plate of the drip line inner frame 2 and the inner side of the wing plate of the drip line outer frame 3 are provided with bayonets 6 corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com