Vacuum glass high-low-temperature observation window device having temperature compensation function

A technology of vacuum glass and observation window, which is applied in parallel glass structure, improvement of windows/doors, adaptation to climate change, etc. It can solve the problem of not being able to play a role in heat insulation and pressure resistance, unusable, and incapable of extreme high and low temperature and large temperature difference. Environmental and other issues, to achieve the best heat insulation function, large viewing angle, and good transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

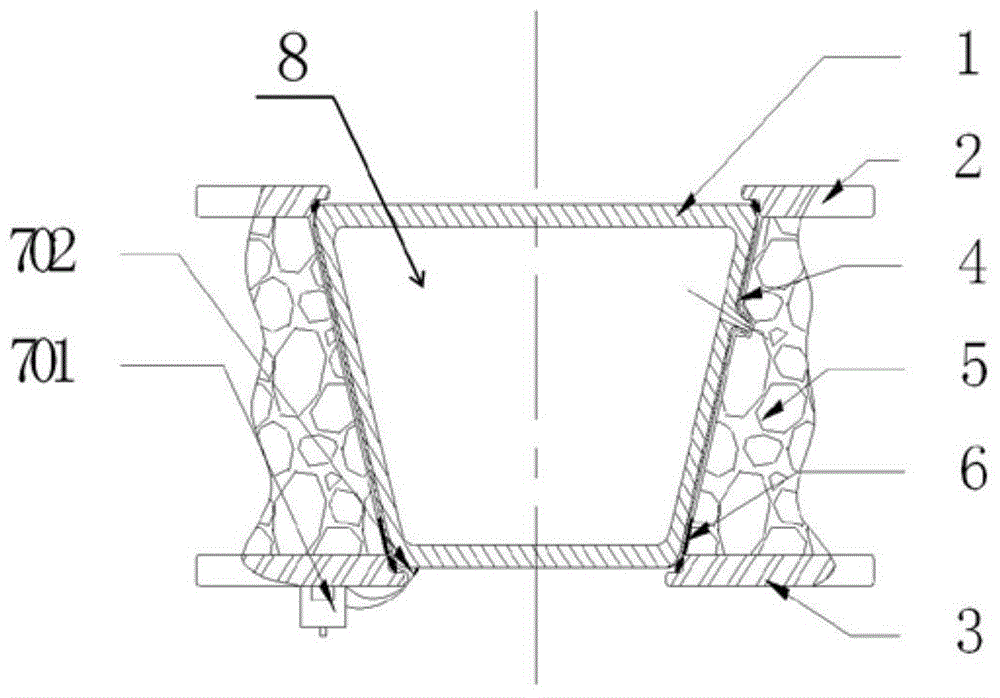

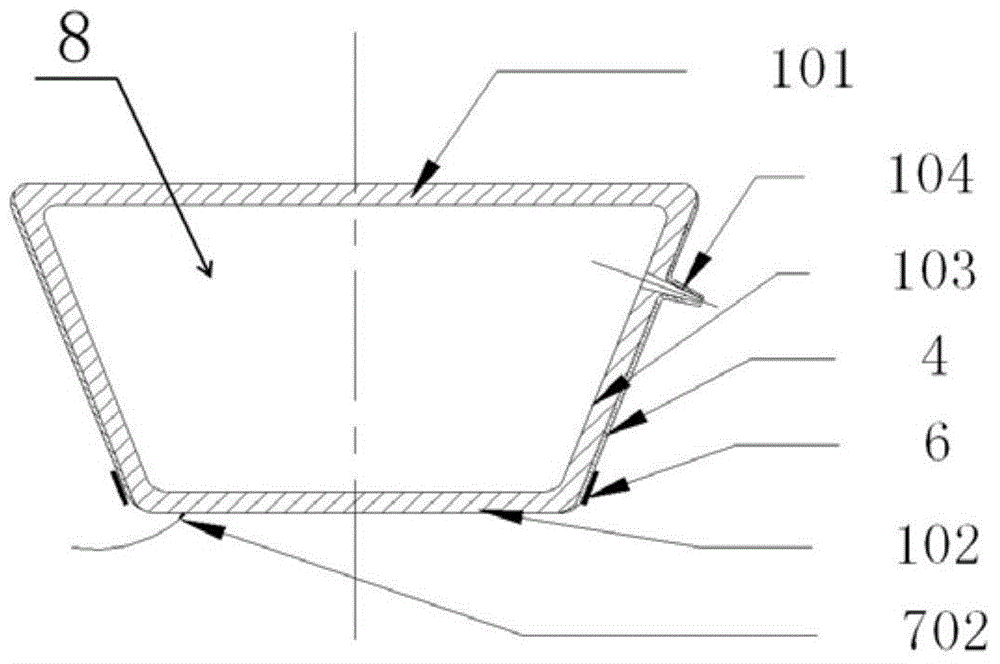

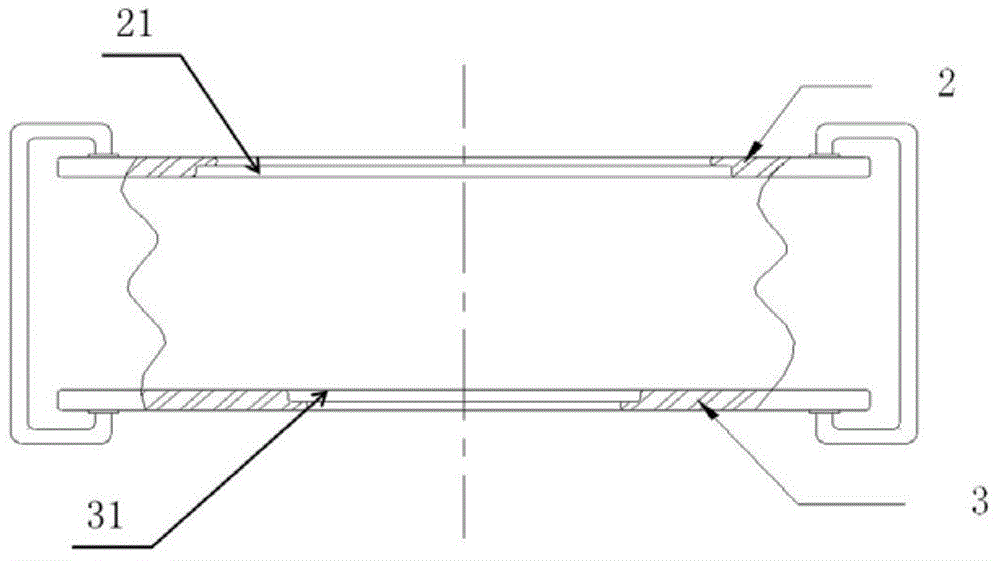

[0026] like figure 1 , figure 2 and image 3 As shown, a preferred embodiment of the present invention provides a vacuum glass high and low temperature observation window device with temperature control compensation, including an observation window 1, the observation window 1 is made of borosilicate glass or quartz glass through glass welding technology The circular frustum structure formed by seamless splicing can ensure its airtightness and strength requirements. Its structure includes the first end surface 101, the second end surface 102 and the side peripheral surface 103. -3 Pa vacuum cavity. The observation window 1 has undergone stress relief treatment and natural cooling process after welding. The outer surface of the side peripheral surface 103 is covered with a reflective layer 4 , and the reflective layer 4 can be formed by plating silver on the outer surface of the side peripheral surface 103 or pasting an aluminum-plated film. The side peripheral surface 103 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com