Anchoring and shotcreting roadway two-side concrete spray layer shear failure prevention and control method

A shear failure and concrete technology, which is applied in earthwork drilling, tunnels, tunnel linings, etc., can solve the shear failure of concrete spray layer, the difficulty in achieving simultaneous deformation, the bearing capacity of roadway, top rock mass and the strength of support body Difficult to play out and other problems to achieve the effect of ensuring long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

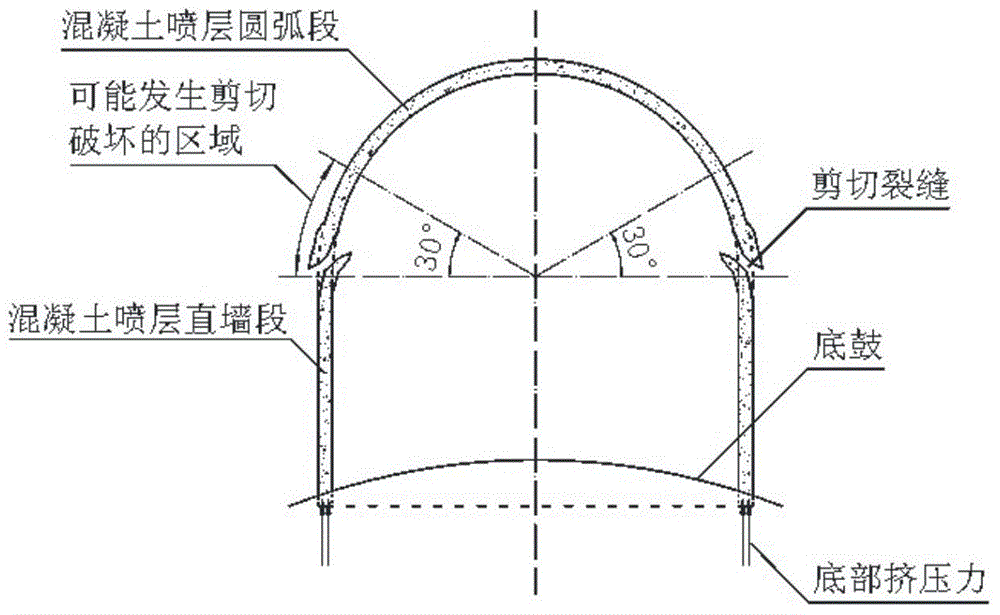

[0017] The method for prevention and treatment of shear failure of two sides of concrete shotcrete in anchor shotcrete roadway of the present invention, its preferred specific implementation mode is:

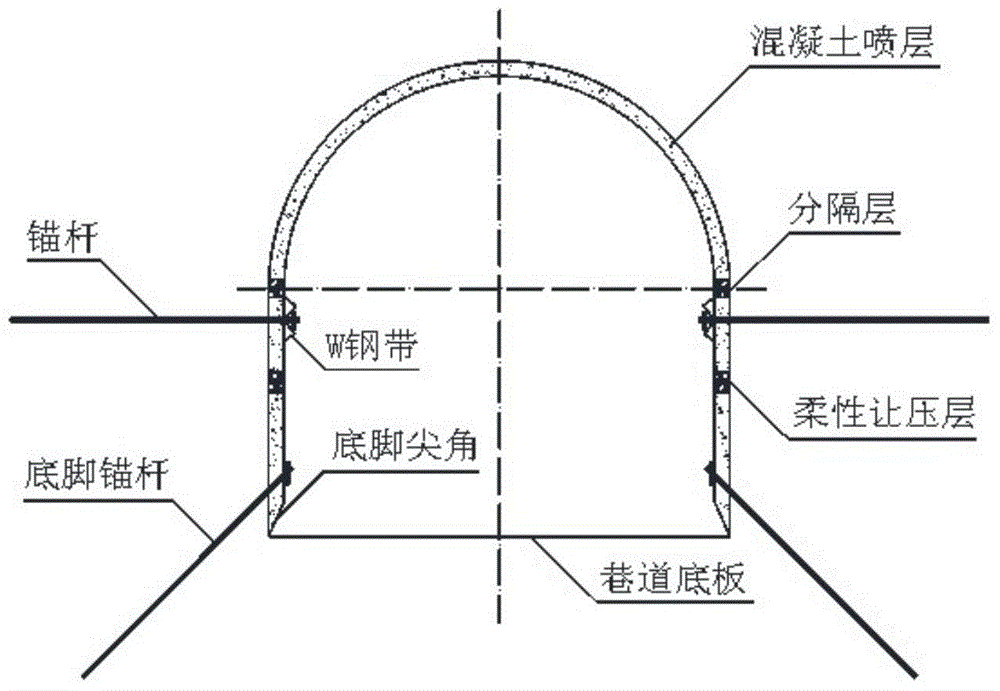

[0018] Two gangs of concrete spraying layers and the arc section concrete spraying layer are arranged in the roadway, a split layer is set between the two gangs of concrete spraying layers and the arc section concrete spraying layer, and the two gangs of concrete spraying layers and the arc section The sprayed concrete layer is separated, and a flexible pressure layer is set in the two sprayed concrete layers.

[0019] The bottom sections of the two gangs of sprayed concrete are triangular with sharp corners facing downward.

[0020] Bottom anchor rods are provided at the bottom of the two gangs of concrete shotcrete.

[0021] An anchor rod and a reinforcing steel belt are arranged on the top of the two gangs of sprayed concrete.

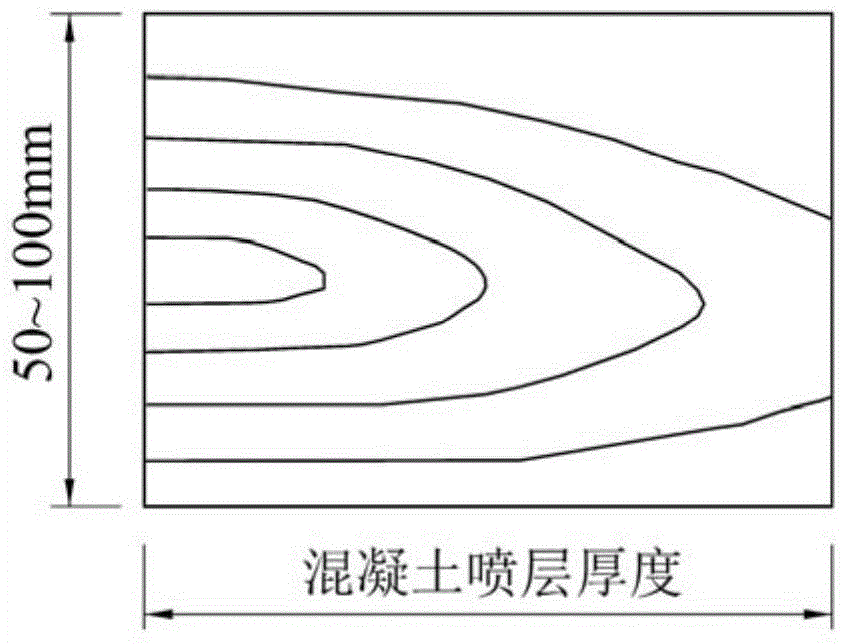

[0022] The cross-section of the reinforcing s...

specific Embodiment

[0027] Specific examples, such as figure 2 shown:

[0028] (1) Separation of the concrete spraying layer of the two sides of the roadway and the concrete spraying layer of the arc section: before spraying the concrete spraying layer, set a dividing strip at the junction of the two sides of the roadway and the arc section, and separate the two sides of the concrete spraying layer and the arc section This technology can effectively solve the problem of shear failure of the concrete sprayed layer in the shoulder area of the roadway caused by the uncoordinated deformation of the sprayed layer on the two sides of the roadway and the sprayed layer on the semicircular arc section in the horizontal direction.

[0029] (2) Set a flexible pressure layer in the two sides of the concrete sprayed layer of the roadway: solve the problem of high rigidity of the concrete sprayed layer and not easily deformed, and promote the surrounding rock of the roadway and the two sides of the concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com