Modular control unit for hydraulic pump and hydraulic motor testing

A modular control, hydraulic motor technology, used in fluid pressure actuation devices, fluid pressure actuation system testing, mechanical equipment, etc., can solve the problems of large auxiliary cooling system, large energy loss, serious system heating, etc., to simplify The effect of system loop design, reduction of auxiliary time, and improvement of test and test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

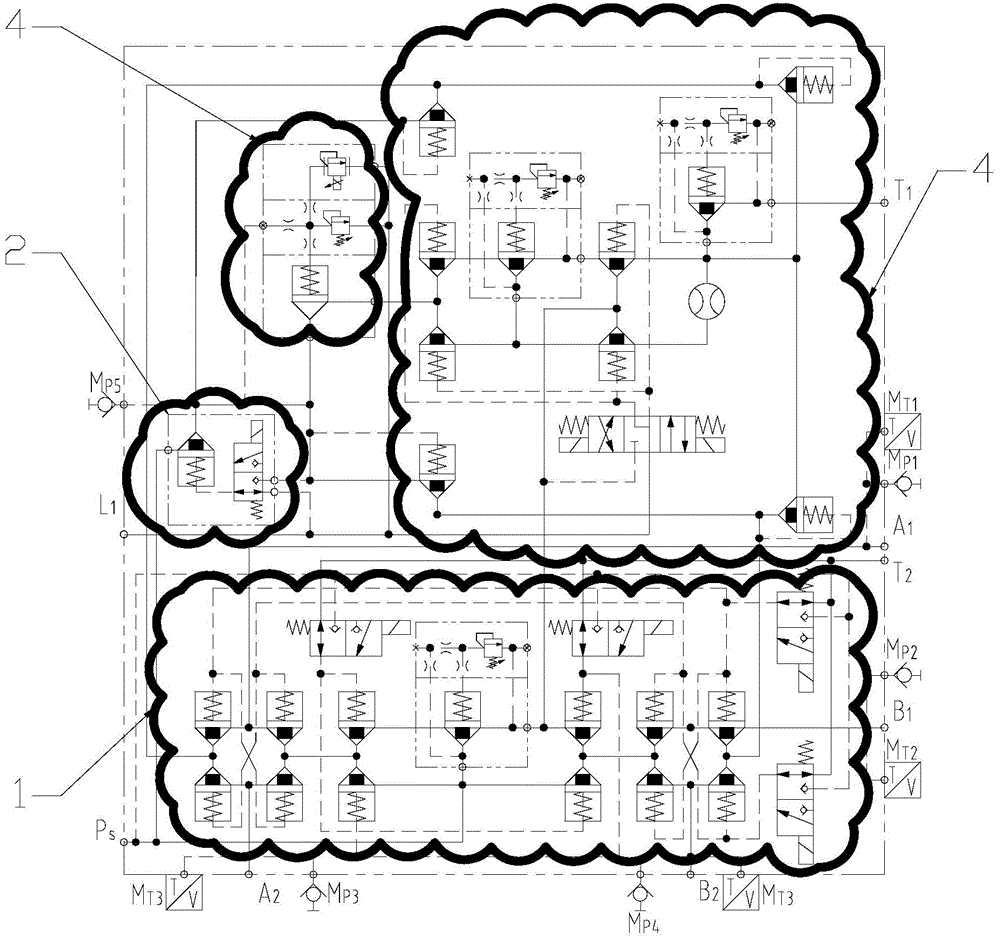

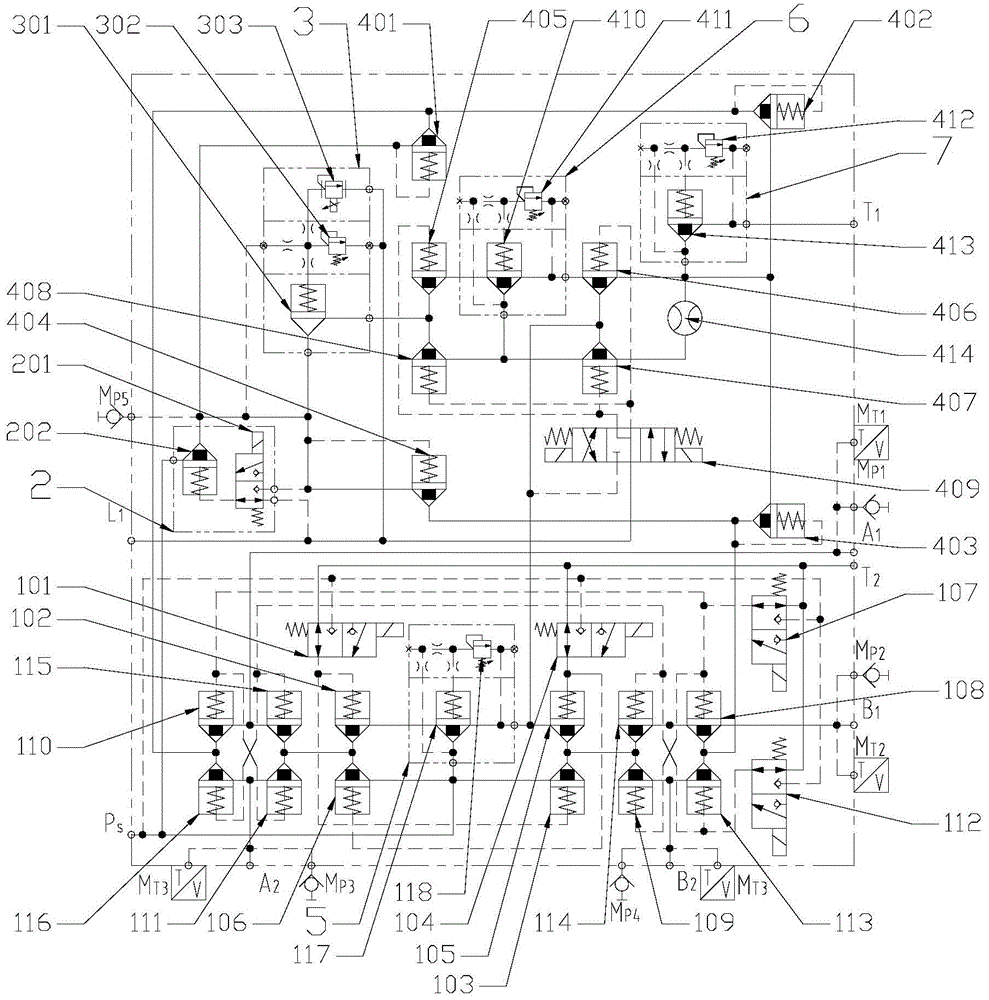

[0040] like figure 1 As shown, the modular control device for testing hydraulic pumps and hydraulic motors of the present invention mainly includes a two-stage reversing module 1, an overflow loading and energy recovery loading switching module 2, an overflow loading module 3 and Return oil flow processing module 4. Each module can be integrated and arranged on the same hydraulic integrated valve block, or can be arranged in separate modules according to actual needs, and the modules are connected by pipelines.

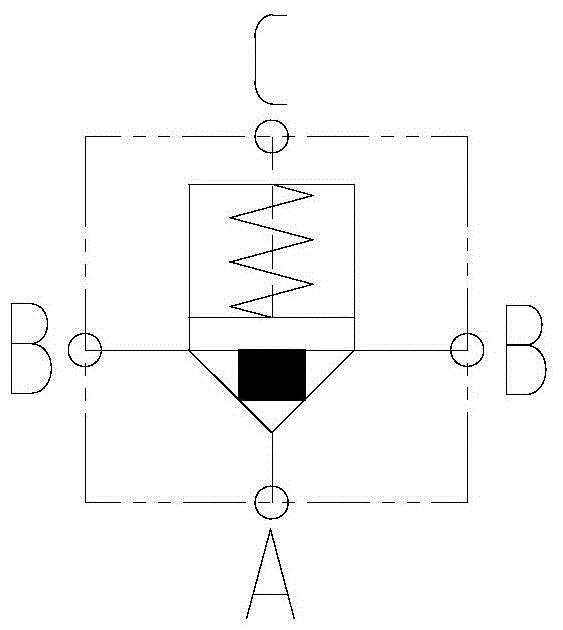

[0041] combine image 3 right figure 2 The internal module connection of the modular control device used for testing hydraulic pumps and hydraulic motors is described. The two-stage reversing module 1 is mainly composed of two-position three-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com