Multiple-point fume temperature monitoring device for power station boiler flue and realizing method of device

A technology for power plant boilers and monitoring devices, applied in measuring devices, thermometers, measuring heat, etc., can solve the problems of difficult measurement technology, limited installation extension length of measuring devices, unsuitable for high-temperature flue gas temperature deviation of power plant boilers, etc. Improvement and reliability of measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

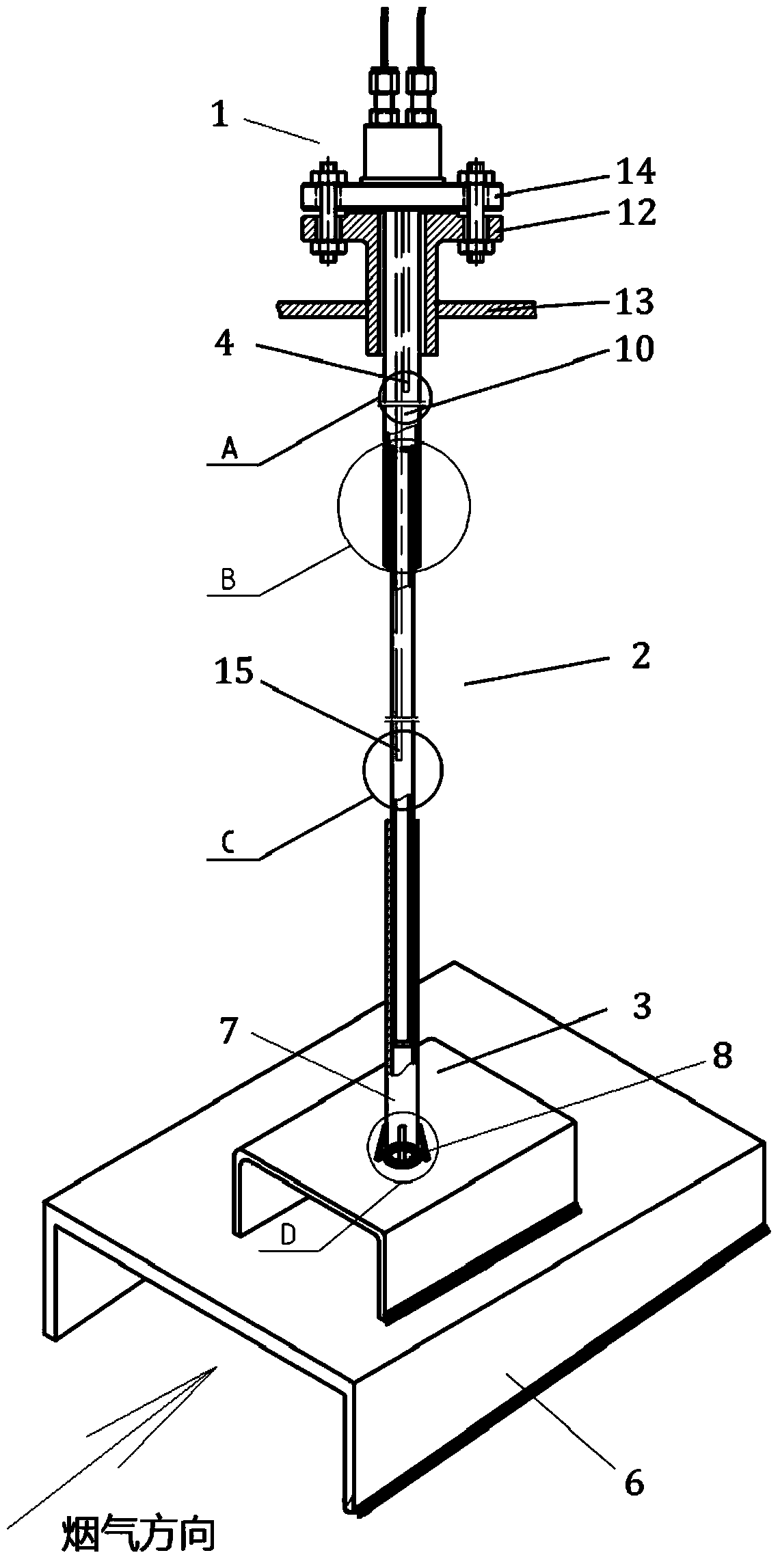

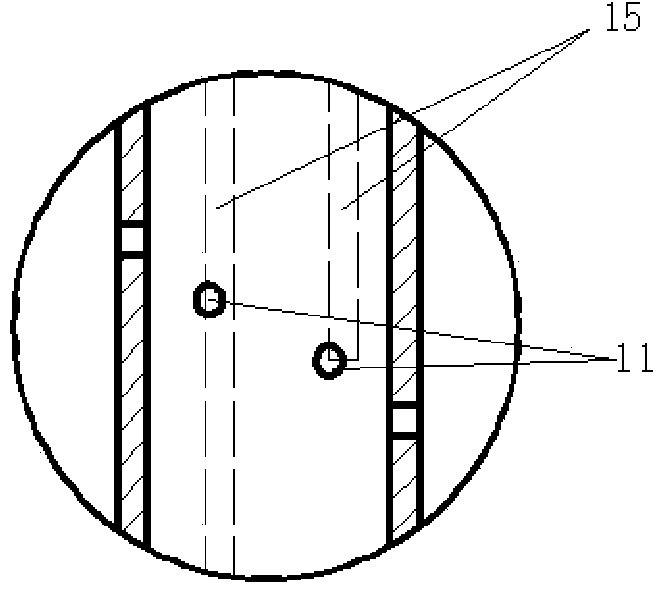

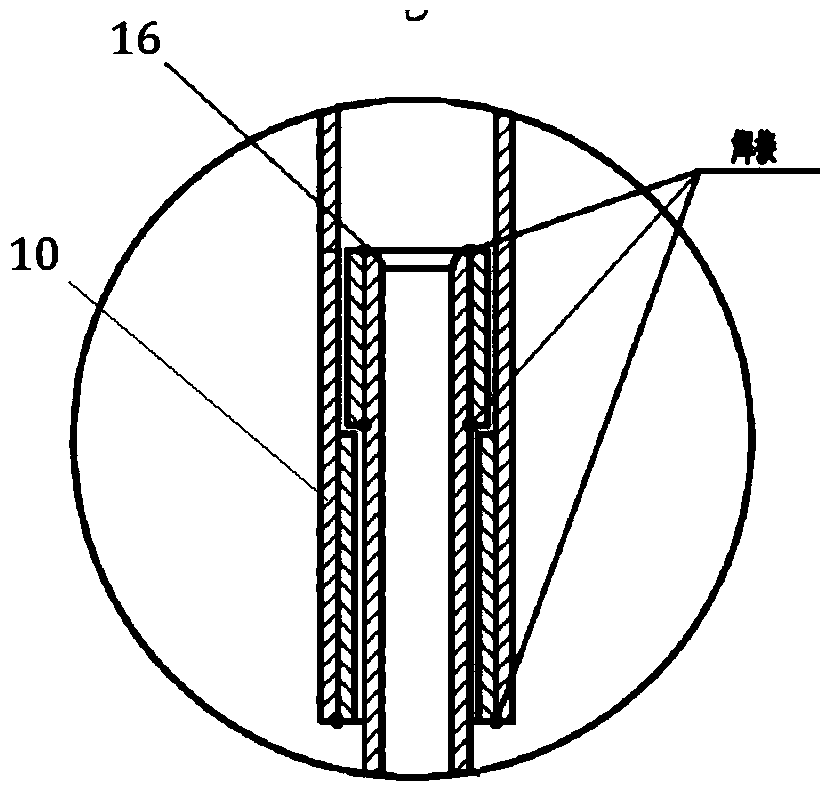

[0028] like figure 1 As shown in -4, this embodiment includes from top to bottom: a base part 1, a telescopic mechanism 2, an anti-vibration mechanism 3, and a plurality of measuring point mechanisms 4 located inside the base part 1 and the telescopic mechanism 2, wherein: the base Part 1 is fixedly installed on the top of the horizontal flue and fixedly connected to one end of the telescopic mechanism 2. The anti-vibration mechanism 3 is fixedly installed on the bottom of the horizontal flue and connected to the other end of the telescopic mechanism 2. The telescopic mechanism 2 is vertically installed at the level of the boiler. In the flue and parallel to the furnace tube 5.

[0029] The anti-vibration mechanism 3 includes: a hollow fixed seat 6 and an anti-vibration tube 7 vertically arranged on the fixed seat 6, wherein: the anti-vibration tube 7 is in contact with the outer wall of the telescopic mechanism 2, and the hollow of the fixed seat 6 The penetration direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com