An arc extinguishing mechanism, a relay frame and a relay

A relay and frame technology, applied in the field of relays, can solve the problems of high cost of all-ceramic frames, arc damage to the plastic frame, etc., and achieve the effects of low cost, improved reliability and electrical life, and simple frame structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the invention is capable of various changes in different embodiments without departing from the scope of the invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

[0047] The orientations such as up, down, top, and bottom mentioned in the present invention are only used to illustrate the relative positional relationship between the components, and do not limit the specific installation orientations of the components in the present invention.

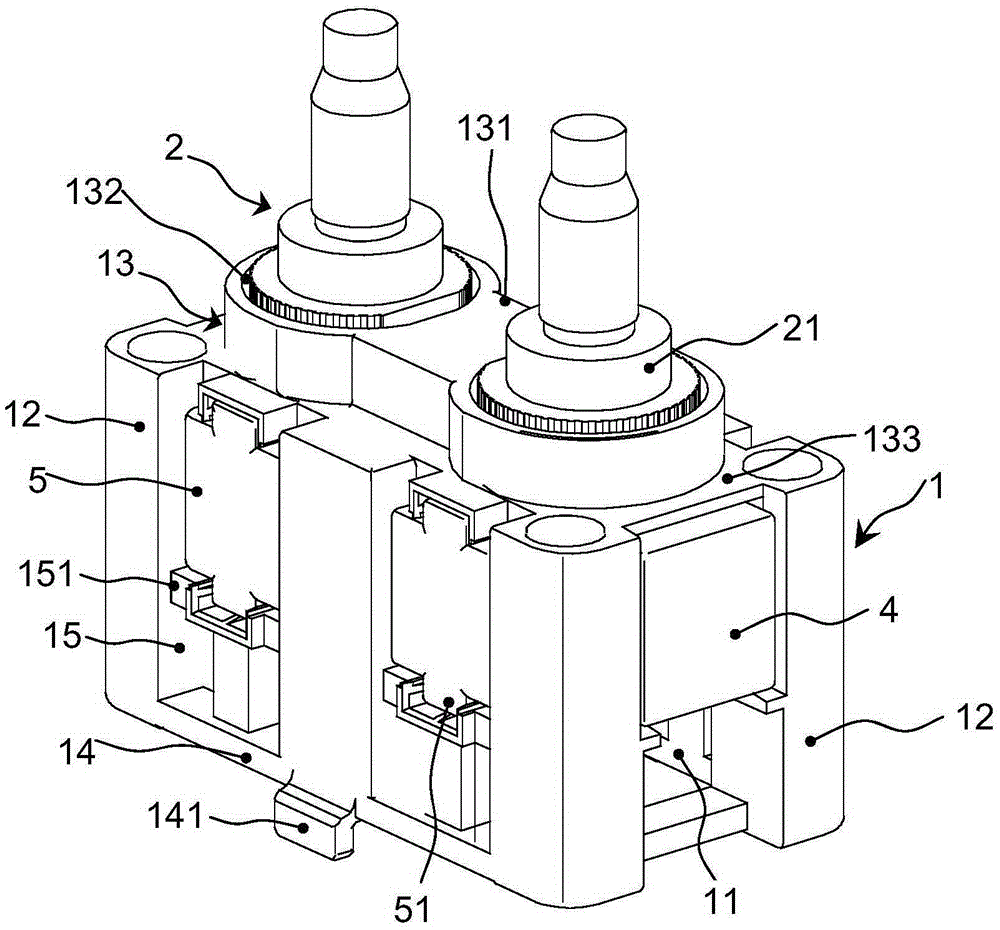

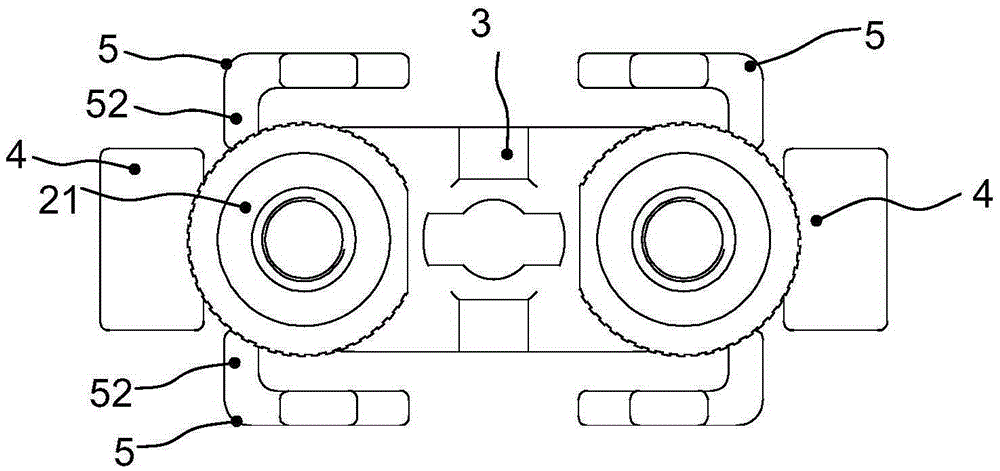

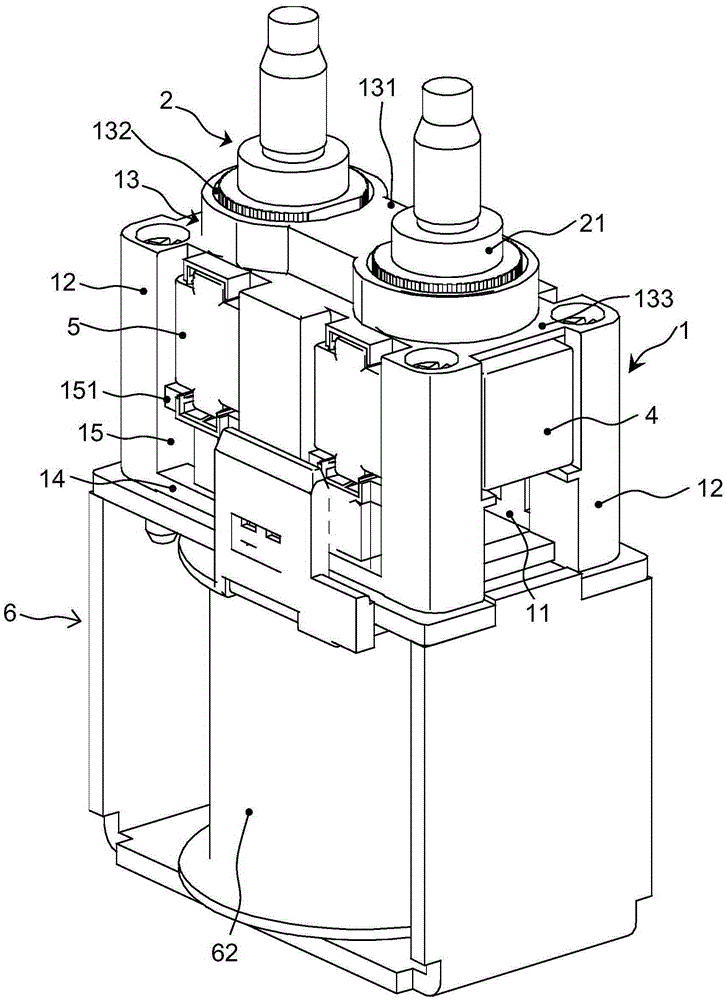

[0048] Such as Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a relay frame, including a frame body 1 , at least one magnetic steel 4 and at least one arc-resistant sheet 5 . An integral hollow portion 11 is formed inside the frame main body 1 , and the hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com