Process for preparing germ soybean milk by using domestic soybean milk machine

A technology of soy milk and germ, applied in applications, dairy products, household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

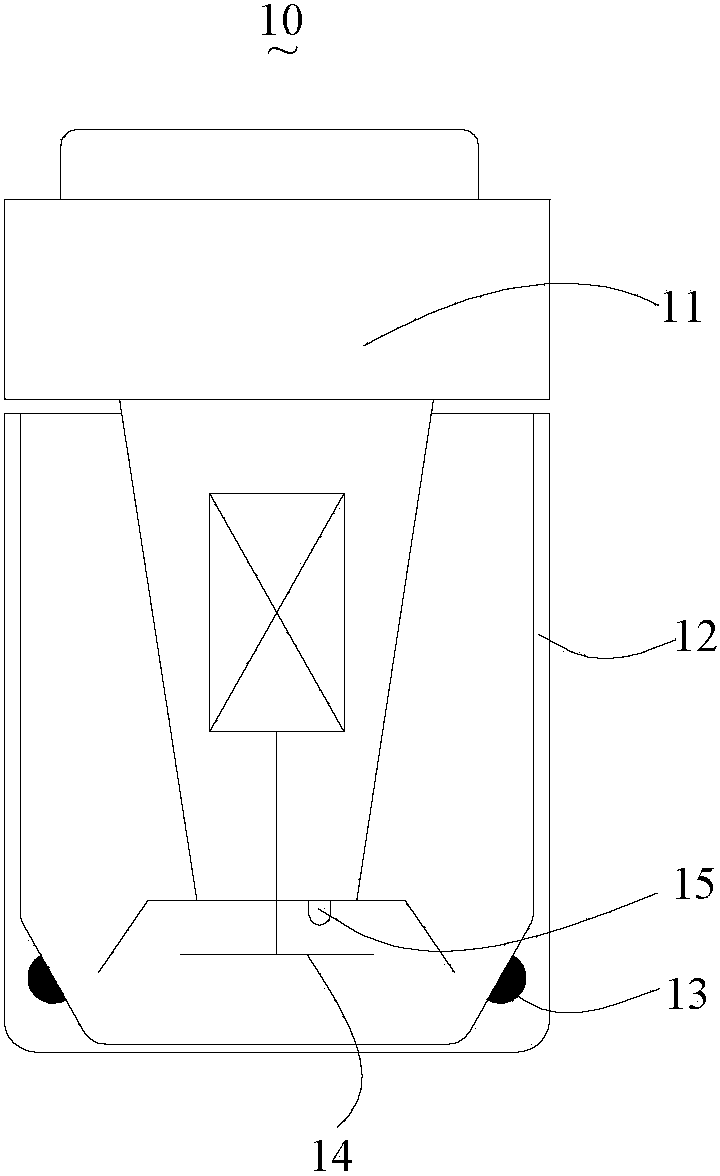

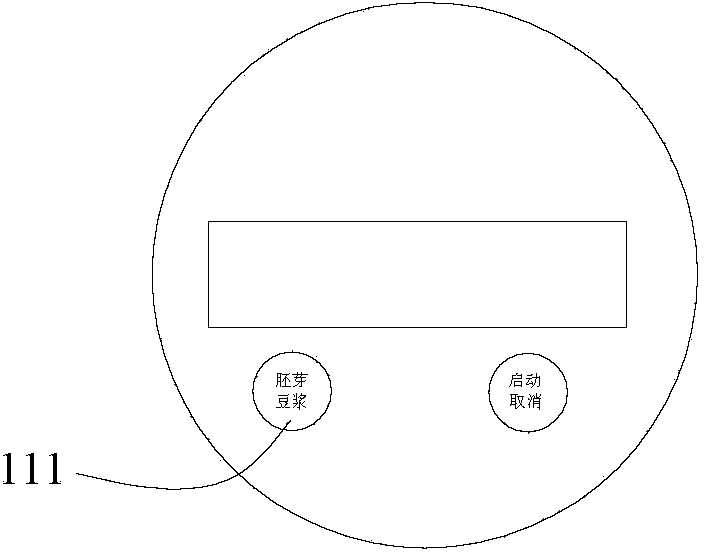

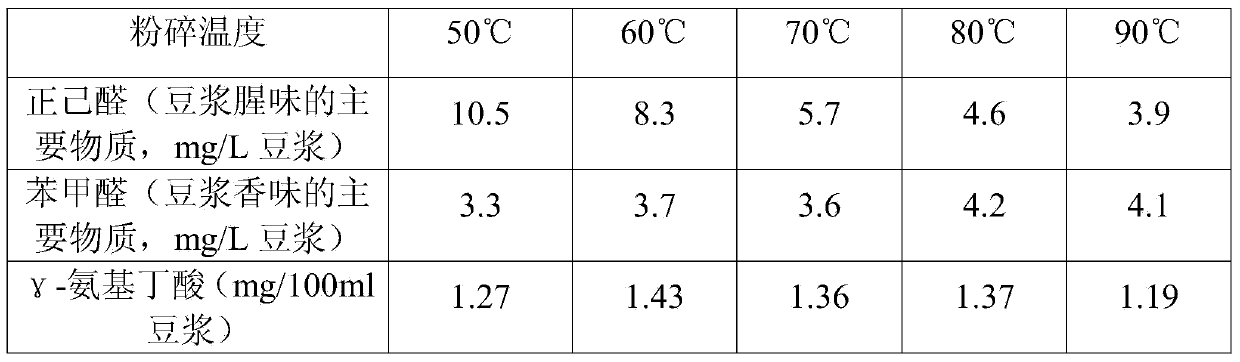

[0036] see figure 1 and figure 2 The schematic diagram of the domestic soybean milk machine used in the first preferred embodiment of the process of making germ soymilk, the household soybean milk machine 10 includes a body 11, a cup body 12, a heating device 13, a crushing device 14, a temperature detection device 15 and a control unit (not shown in the figure), the heating device 13, the pulverizing device 14 and the temperature detection device 15 are respectively electrically connected to the control unit, and the shell of the body 11 is provided with a function key 111 of "germ soymilk" for starting to make germ soymilk. Germ soybean milk" function key 111 is electrically connected with the control unit, and the control unit includes a main control chip, and the master control chip is burnt with a pulping program for making germ soybean milk.

[0037] The present invention utilizes household soybean milk machine 10 to make the technique of germ soybean milk, comprises t...

Embodiment approach 2

[0061] The difference between the second embodiment and the first embodiment of the process of using a household soymilk maker to make germ soymilk is that: (a) before the heating step, it also includes a germination step of using the household soymilk maker itself to germinate the soymilk directly. Put into the cup, add an appropriate amount of water, the temperature in the cup is detected by the temperature detection device and fed back to the control unit, the control unit controls the heating state of the heating device, so that the temperature t1 in the germination step is maintained at 20 to 30 °C, and the germination time is 6 to 30 °C. 48 hours.

[0062] In this embodiment, in the germination step, the water used for germination is first poured out, and then enters the next heating step after adding water, especially in summer, the germination water is easy to smell, and the user can also carry out heating in the germination step. Change the water several times to achi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com