Vacuum freeze-drying technology of tangerine peeling

A technology of vacuum freeze-drying and decapsulation, applied in application, food processing, food science, etc., can solve the problems of other substances residues, etc., and achieve the effect of complete fruit, natural color and unchanged taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] This embodiment provides a vacuum freeze-drying process for decapsulating citrus, including the following steps:

[0035] First, the choice of citrus raw materials: citrus raw materials should be selected with dense flesh, bright and beautiful color, no extrusion deformation, no mechanical damage, no disease and insect pests, and no rot;

[0036] Second, raw material storage

[0037] The raw materials are stored in plastic baskets, and the "four distances" (off the ground, off the wall, off the ceiling, off the batch) are placed in a ventilated, dark, -1~3℃ fresh-keeping warehouse;

[0038] Third, sorting

[0039] Grading according to the size of the fruit's horizontal diameter, 45-55 mm, 55-65 mm, 65-75 mm and more than 75 mm; remove foreign objects such as orange leaves and branches;

[0040] Fourth, cleaning

[0041] Use a hair bubble cleaning machine to clean to ensure that the oranges are free of sediment, cords, branches and leaves and other foreign objects;

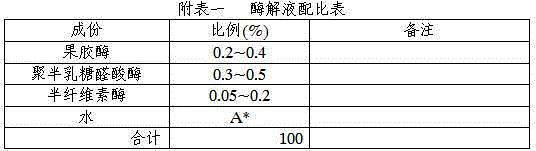

[0042] Fifth, pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com