Driving device for exerting a translatory and rotary motion on a drive shaft for driving a deburring tool and method for the operation thereof

A technology of drive device and drive shaft, which is applied in the direction of drive device, feeding device, parts of boring machine/drilling machine, etc., can solve the problems of complex device composition, inability to perform fast movement, wear and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

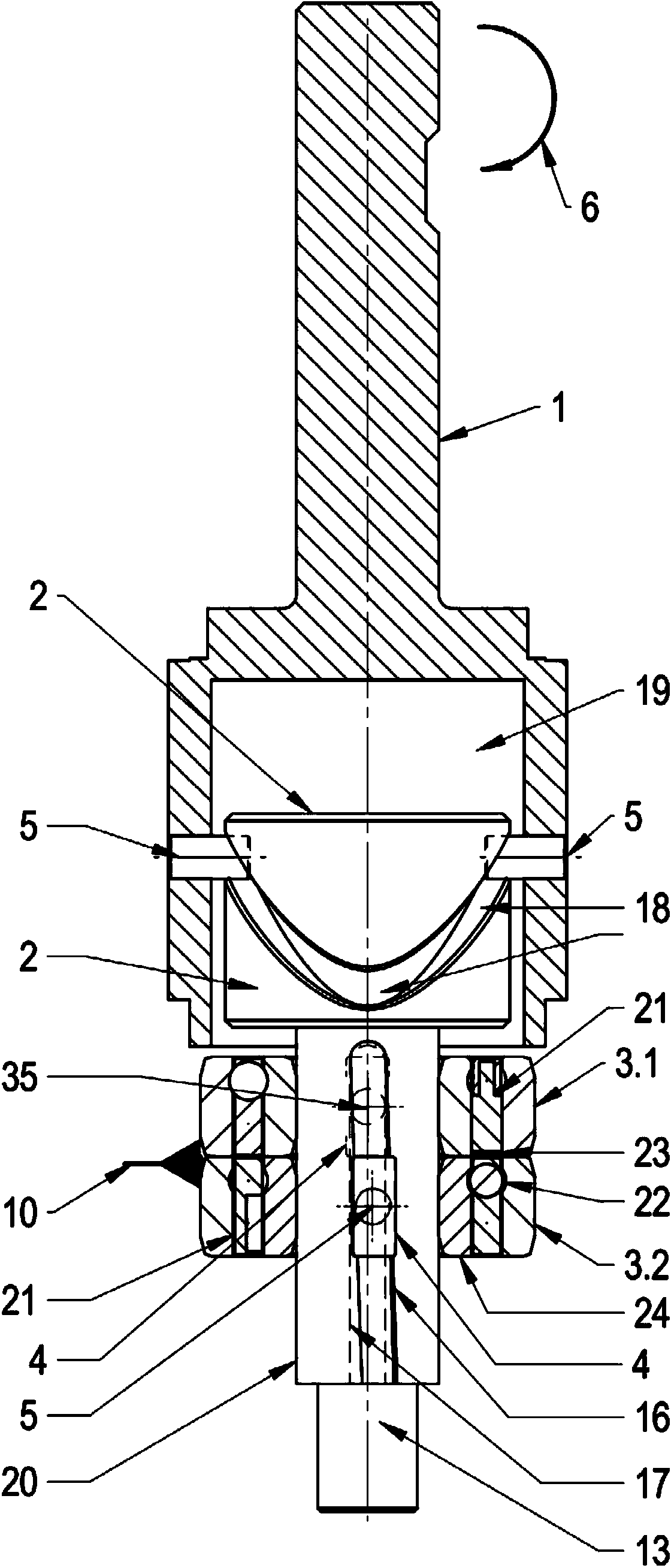

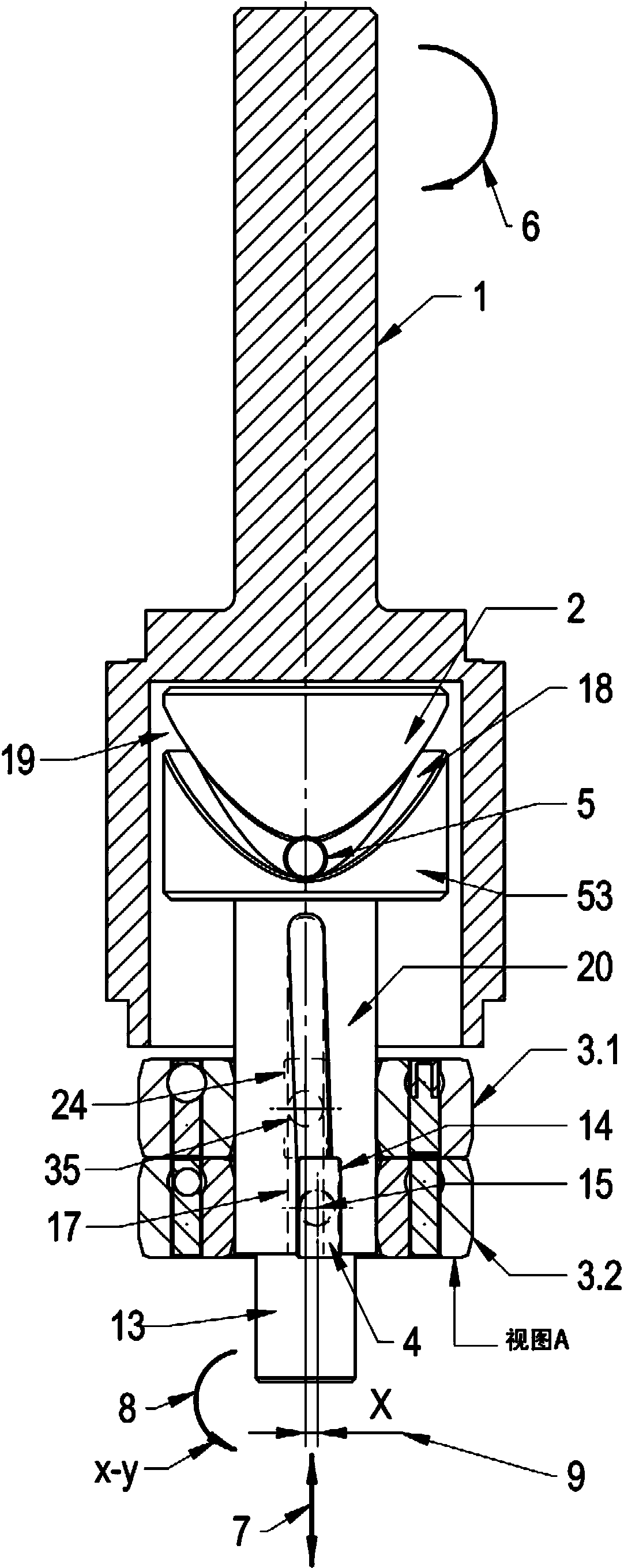

[0048] The drive shaft 1 is inserted, not further shown, into a chuck of a rotationally driven drive machine and is driven rotationally, for example in the direction of the arrow 6 .

[0049] The drive shaft 1 is widened in the form of a cylindrical body, which is formed with a cylindrical guide hole 19 which is designed to be open at the bottom at the bottom.

[0050] Arranged in the inner chamber of the guide hole 19 is a cam body 2, which substantially consists of a cylindrical upper part, on whose outer circumference extends a circumferentially closed sinusoidal drive cam extending over the entire circumference, its unfolding in Figure 12 shown in .

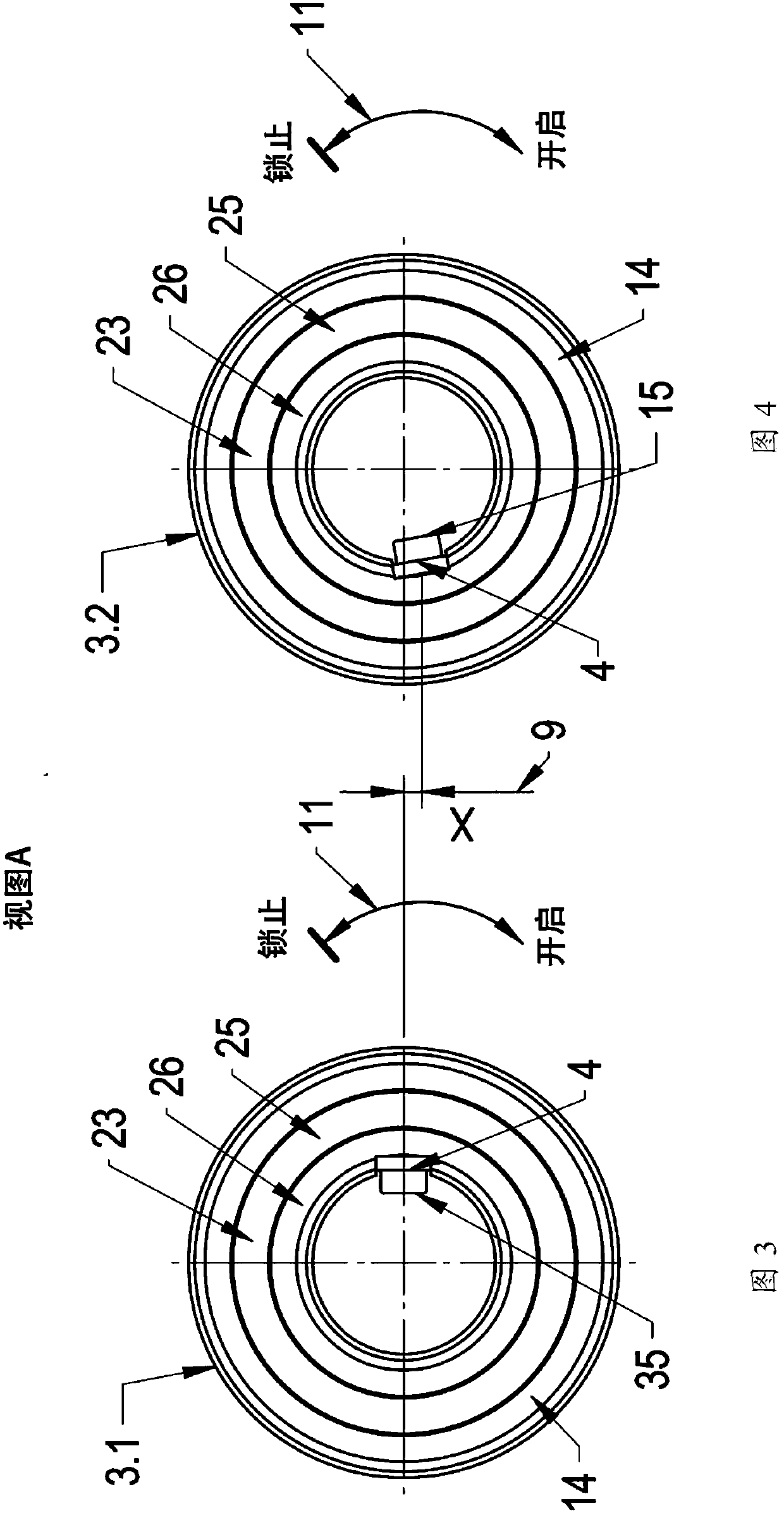

[0051] The drive cam 18 is designed as a deepened groove machined on the circumference of the cam body 2 , which is open to the outside. Engaged in the drive cam 18 are pins 5 offset from one another at an angle of 180°, which are fastened on a cylinder 54 of the drive shaft 1 and are positively engaged with their radially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com