Lap-joint solder-free friction-stir direct solid-phase crimping method

A friction stir, lap joint technology, used in welding/welding/cutting items, welding equipment, non-electric welding equipment, etc., can solve problems such as difficulty, interface oxide film dispersion and poor vertical mixing, needle wear and breakage, etc. Achieve the effect of increasing productivity, reducing costs, and simplifying processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

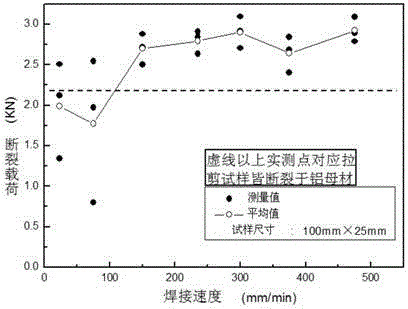

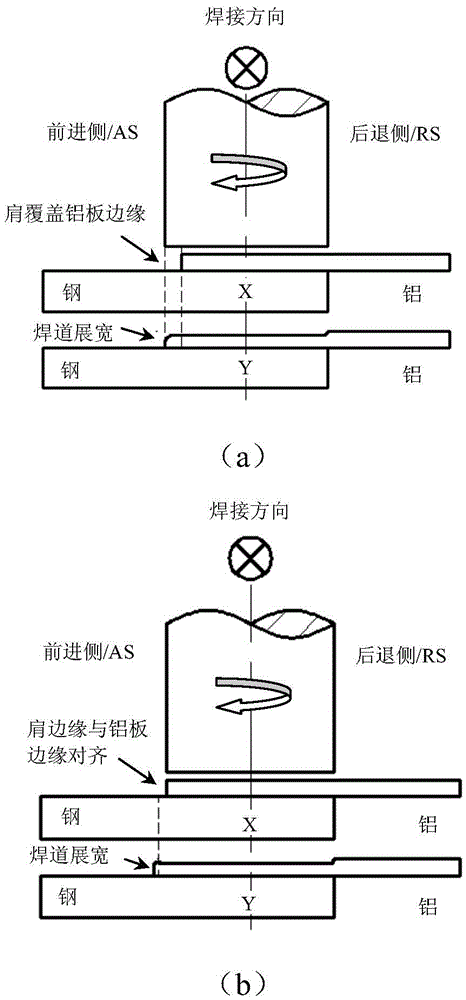

[0036] The present invention involves two methods in terms of stirring tool alignment, one, as figure 1 (b) method, align the shoulder edge of the stirring tool with the outer edge of the aluminum plate; figure 1 (a) method, cover the edge of the aluminum plate with the shoulder of the stirring tool. The difference between these two methods is that compared with the alignment method used in method 2, in method 1, there are more aluminum base materials under the stirring tool shoulder under the stirring friction. Therefore, in the welding process, a large amount of aluminum material is extruded out of the stirring tool shoulder after softening, that is, the weld bead widening effect is obvious; and in method 2, a small amount of widening aluminum material covers the lower part of the stirring tool shoulder, and this part of the widening aluminum material is affected. The strong interface torsion and forging effects are beneficial to the mechanical membrane breaking effect and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com