A bionic flexible body that can bend sideways and up and down

A lateral bending and body technology, which is applied in motor vehicles, transportation and packaging, etc., can solve the problems that have not been reported in the research of bionic flexible body of quadruped robots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

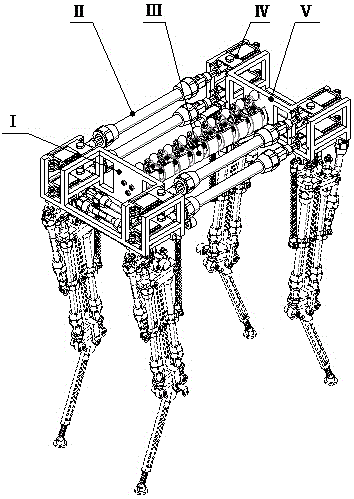

[0020] like Figure 1~Figure 4 As shown, a bionic flexible body that can bend sideways and up and down according to the present invention consists of a front body (I), a rear body (V), 4 sets of pneumatic artificial muscle components (II), and a bionic spine (Ⅲ) and 4 pairs of slider moving mechanisms (Ⅳ); it is characterized in that: the front body (I) and the rear body (Ⅴ) are space frame structures; 4 sets of pneumatic artificial muscle components (II) pass through 4 pairs The slider moving mechanism (Ⅳ) is connected with the front body (Ⅰ) and the rear body (Ⅴ), of which 2 groups are installed on the left side of the body, and the other 2 groups are installed on the right side of the body, and the 2 groups on the same side are arranged in parallel up and down; the bionic spine (Ⅲ) The front and rear ends are respectively connected with the front body (I) and the rear body (V) by screws.

Embodiment 2

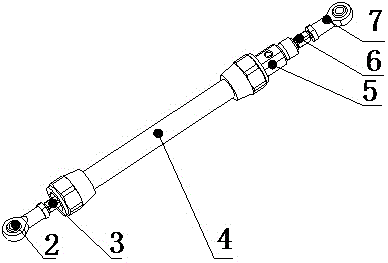

[0022] see figure 2 , this embodiment is basically the same as Embodiment 1, the special feature is: the pneumatic artificial muscle assembly (II) includes 2 joint bearings (2, 7), 2 threaded rods (3, 6), 1 pneumatic artificial muscle (4) and 1 air-connecting piece (5). One of the joint bearings (2) is connected to one end of the pneumatic artificial muscle (4) through a threaded rod (3); while the other joint bearing (7) is connected to the pneumatic artificial muscle (4) through another threaded rod (6) and the air connection piece (5). The other end of the artificial muscle (4) is connected; wherein the air-connecting part (5) has an air-connecting hole to communicate with the inner cavity of the pneumatic artificial muscle (4) to inflate and deflate it.

Embodiment 3

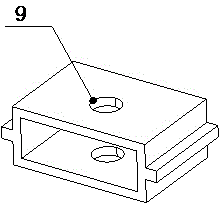

[0024] see image 3 , this embodiment is basically the same as Embodiment 1, and the special features are: the four pairs of slider moving mechanisms (IV) have the same structure, and each slider moving mechanism (IV) includes a front body (I), a cylinder (8 , 26, 25, 24, 16, 17, 19, and 20), sliders (9, 13, 22, 23, 15, 14, 18, and 21). The front body (I) and the rear body (V) are respectively provided with rectangular grooves forming moving pairs with the sliders (9, 13, 22, 23, 15, 14, 18 and 21); the cylinders (8, 26, 25, 24, 16, 17, 19 and 20) are fixed on the front body (I); the piston of the cylinder is connected with the slide block, and the slide block can be moved between the front body (I) and the rear body by charging and deflated air to the cylinder. (Ⅴ) on the rectangular groove slide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com