Porous artificial nerve stent and preparation method thereof

An artificial nerve and uniform technology, applied in medical science, tissue regeneration, prosthesis, etc., can solve secondary injuries and other problems, and achieve the effect of promoting repair, high preparation efficiency, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

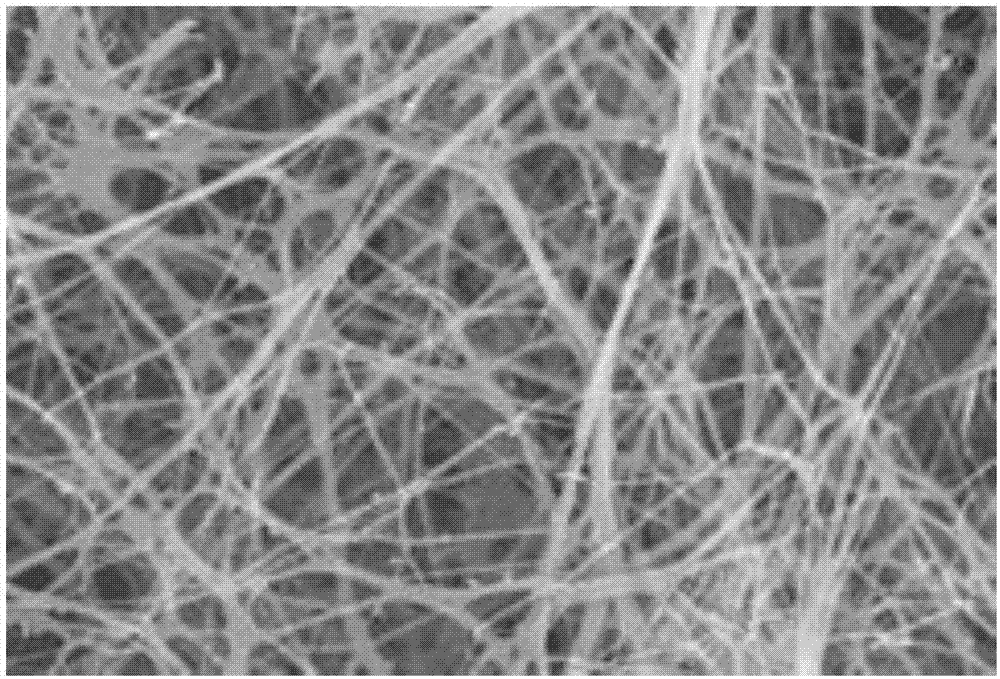

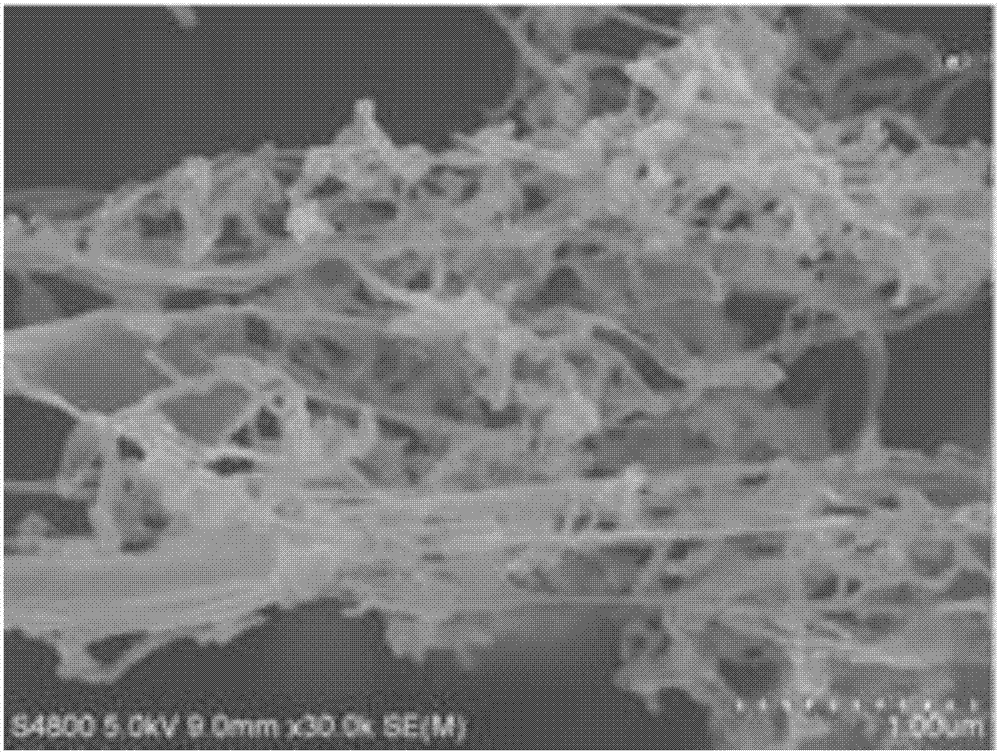

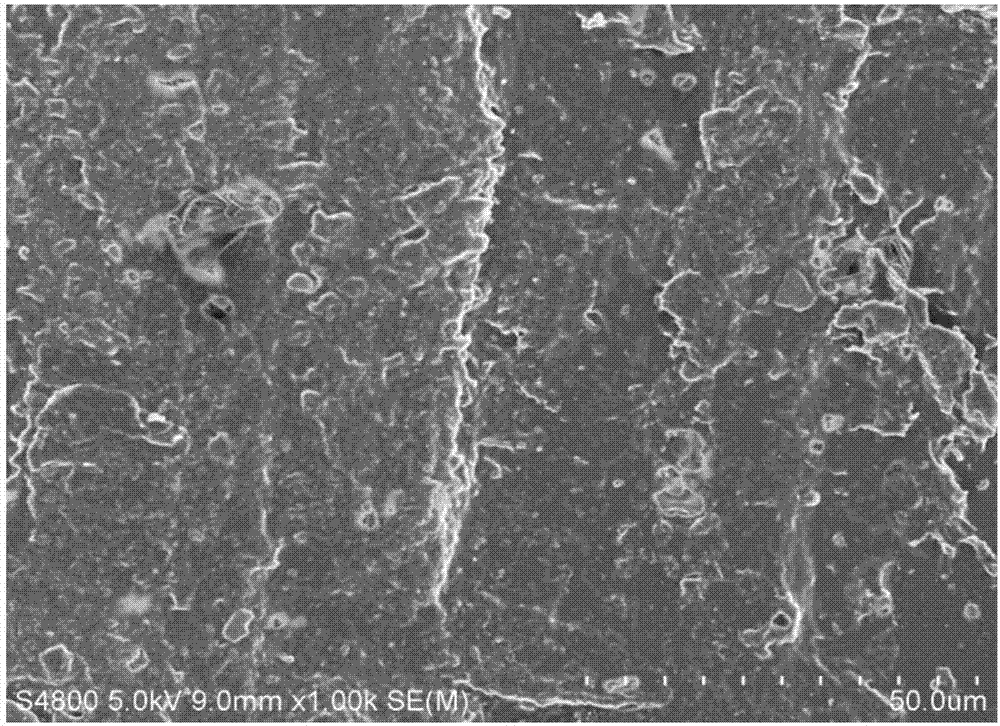

[0033] Using an electronic balance, weigh a certain amount of bacterial cellulose, configure 1L of 1% NaOH aqueous solution, heat it to 90°C with a magnetic stirrer, cut the bacterial cellulose into small pieces and immerse it in it, boil for 30 minutes, cut and disperse it with a mixer for about 5 minutes, Discard the supernatant after centrifuging at 1000rpm for 10min, wash with deionized water until neutral, add 60wt% sulfuric acid solution, perform hydrolysis in a water bath at 50°C in a constant temperature heating magnetic stirrer for 3h, add deionized water to the hydrolyzate After dilution, the diluted solution was centrifuged at 2000rpm for 10min, the supernatant was discarded, and an appropriate amount of NaOH solution was added to adjust the pH value to neutrality, then put into a dialysis bag, and dialyzed with ultrapure water for 3 days, during which time the water was changed every 4h. Freeze in a -80°C refrigerator for 1 hour, and then freeze-dry in a freeze drye...

Embodiment 2

[0035] Using an electronic balance, weigh a certain amount of bacterial cellulose, configure 1L of 1% NaOH aqueous solution, heat it to 90°C with a magnetic stirrer, cut the bacterial cellulose into small pieces and immerse it in it, boil for 30 minutes, cut and disperse it with a mixer for about 5 minutes, Discard the supernatant after centrifuging at 1000rpm for 10min, wash with deionized water until neutral, add 60wt% sulfuric acid solution, perform hydrolysis in a water bath at 50°C in a constant temperature heating magnetic stirrer for 2h, add deionized water to the hydrolyzate After dilution, the diluted solution was centrifuged at 2000rpm for 10min, the supernatant was discarded, and an appropriate amount of NaOH solution was added to adjust the pH value to neutrality, then put into a dialysis bag, and dialyzed with ultrapure water for 3 days, during which time the water was changed every 4h. Freeze in a -80°C refrigerator for 1 hour, and then freeze-dry in a freeze drye...

Embodiment 3

[0037] Using an electronic balance, weigh a certain amount of bacterial cellulose, configure 1L of 1% NaOH aqueous solution, heat it to 90°C with a magnetic stirrer, cut the bacterial cellulose into small pieces and immerse it in it, boil for 30 minutes, cut and disperse it with a mixer for about 5 minutes, Discard the supernatant after centrifuging at 1000rpm for 10min, wash with deionized water until neutral, add 60wt% sulfuric acid solution, perform hydrolysis in a water bath with a constant temperature heating magnetic stirrer at 50°C, add deionized water to the hydrolyzate for dilution After dilution, the solution was centrifuged at 2000rpm for 10min, the supernatant was discarded, and an appropriate amount of NaOH solution was added to adjust the pH value to neutrality, put into a dialysis bag, and dialyzed with ultrapure water for 3 days, during which the water was changed every 4h, - Freeze in a refrigerator at 80° C. for 1 hour, and then freeze-dry in a freeze dryer to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com