Diatom mud and preparation method thereof

The technology of diatom mud and diatomite is applied in the field of interior decoration and decoration materials, which can solve the problems of air purification limitation and low removal rate of harmful substances, and achieve the effects of improving degradation rate and removal rate and beautiful interior decoration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The present invention also provides a kind of preparation method of above-mentioned diatom ooze, it comprises the following steps:

[0019] Fully soak the diatomite with acid to remove the water-soluble impurities therein, filter the acidified diatomite with deionized water to remove impurities and dry it to obtain purified diatomite; then mix the purified diatomite with mica, The cellulose, talcum powder, titanium platinum, and shadowless glue are thoroughly mixed, and finally water is added and stirred for two to three hours to obtain the diatom mud.

[0020] Furthermore, the above steps specifically also include: fully soaking the diatomite with sulfuric acid, nitric acid or hydrochloric acid for 5-10 hours to remove water-soluble impurities therein, the mass of the diatomite and sulfuric acid, nitric acid or hydrochloric acid The ratio is between 1:10-1:50.

Embodiment 1

[0023] 2 kilograms of diatomite, 0.25 grams of mica, 0.12 grams of cellulose, 1.75 kilograms of talcum powder, 0.15 grams of titanium platinum and 0.25 grams of shadowless glue, and the balance is water, and diatoms are prepared according to the above-mentioned preparation method The mud was then applied to the interior wall of a 15-square-meter house, and the house was closed for 45 days to test indoor harmful substances. The concentration of formaldehyde was 0.07 mg per cubic meter.

Embodiment 2

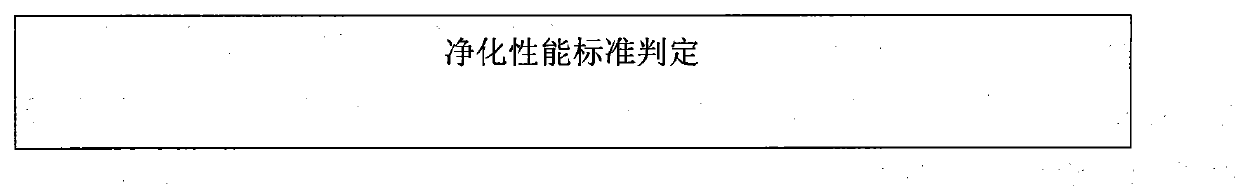

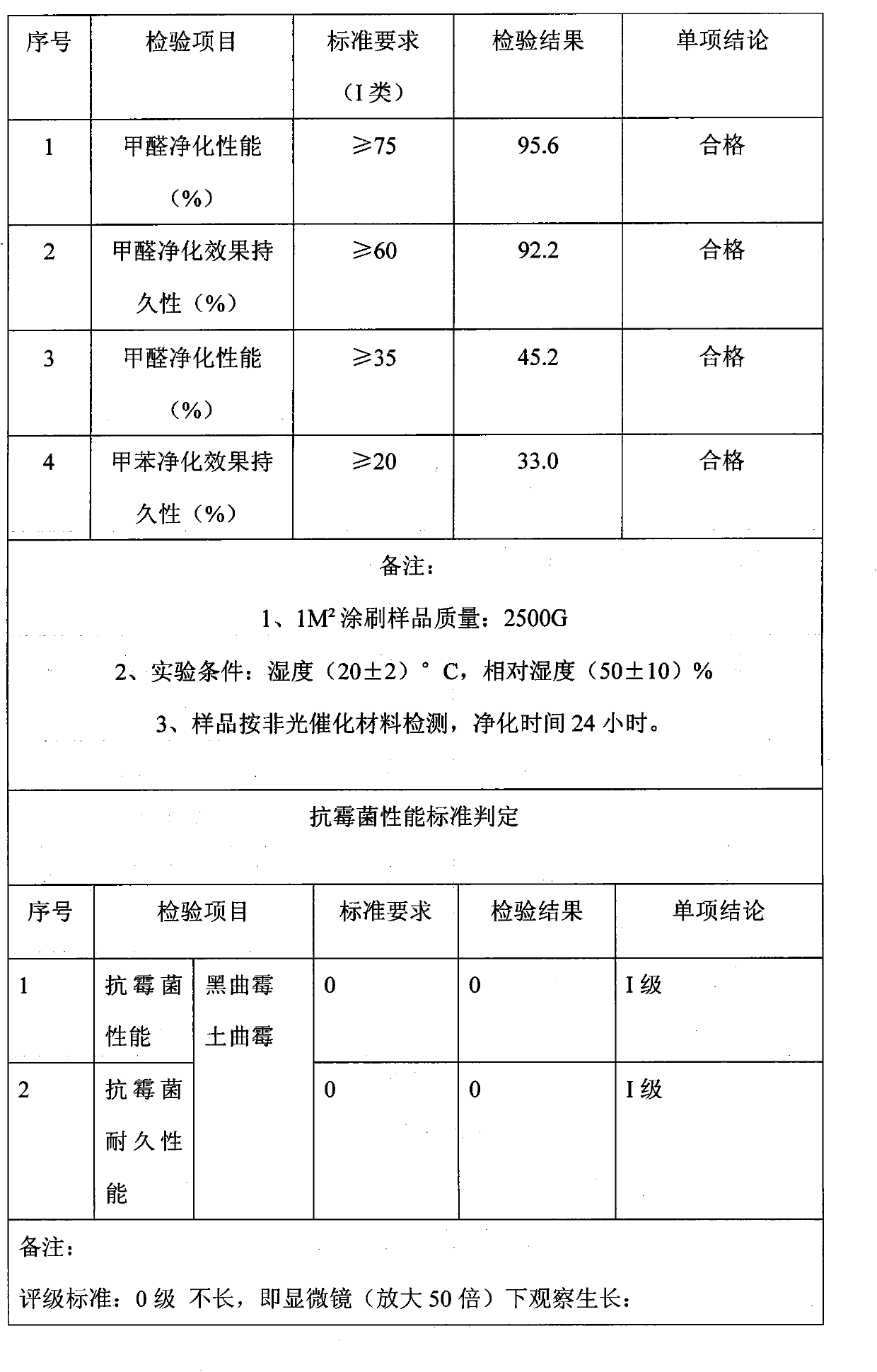

[0025] 300 kilograms of diatomite, 50 grams of mica, 18 grams of cellulose, 120 kilograms of talcum powder, 20 grams of titanium platinum and 30 grams of shadowless glue, the balance is water, and diatoms are prepared according to the above-mentioned preparation method The mud was then applied to the interior wall of a 400-square-meter house, and the house was closed for 50 days to test indoor harmful substances. The concentration of formaldehyde was 0.05 mg per cubic meter. As shown in Table 1 about the purification status,

[0026] Table 1

[0027]

[0028]

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com