Static cracking equipment

A kind of equipment and static technology, applied in the field of static cracking equipment, can solve the problems of easy blockage of cooling system pipes, falling off of steel plates, short service time, etc., and achieve the effects of good color and purity, safe use and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

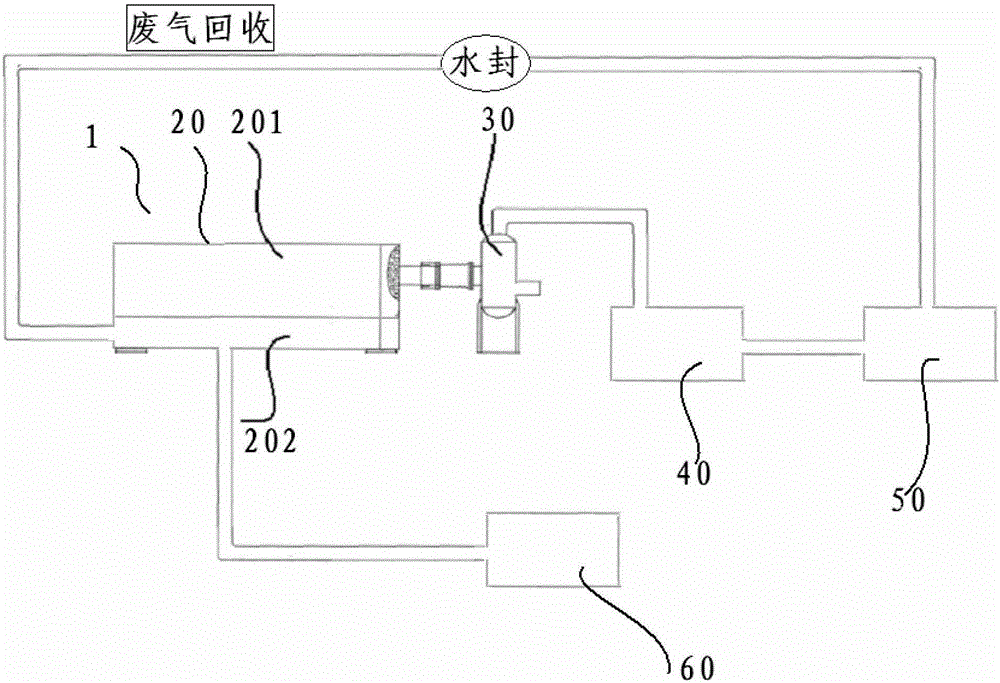

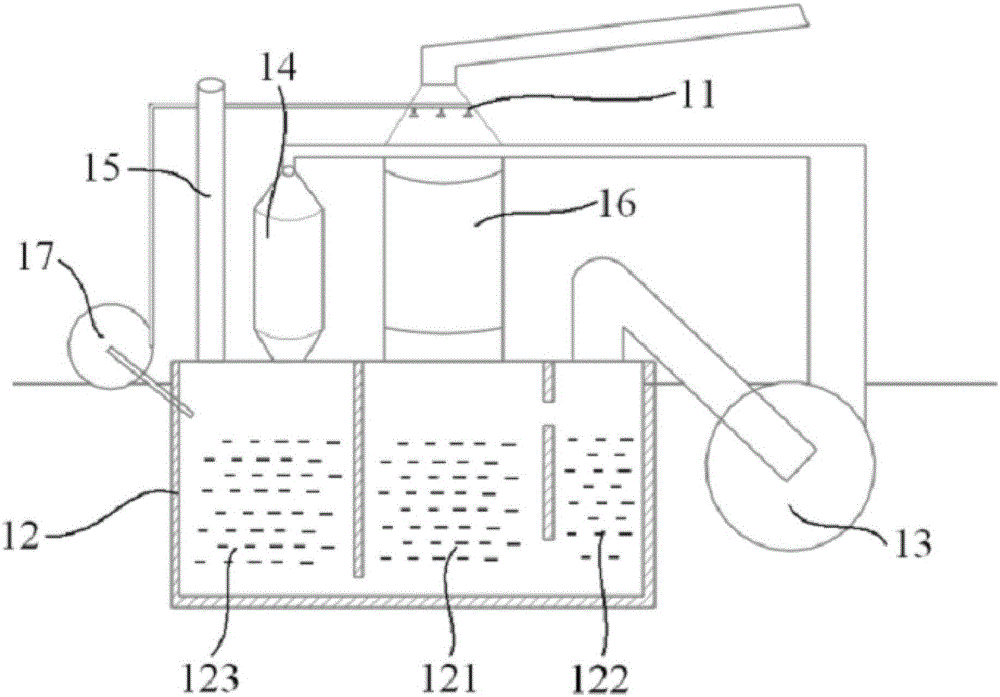

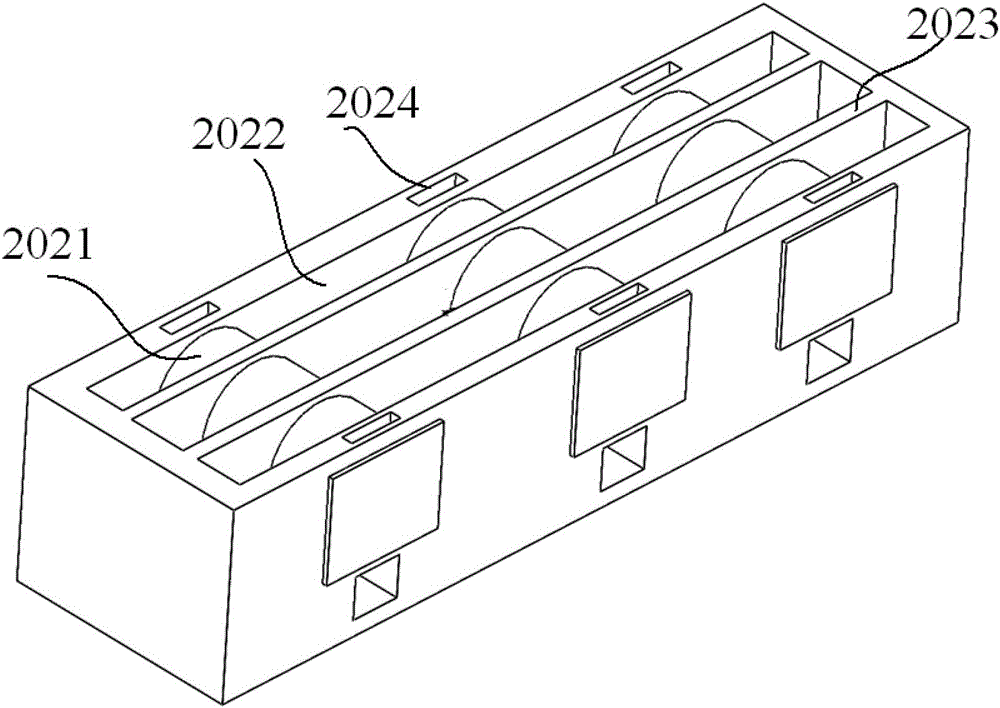

[0028] see Figure 1-4 Said: static cracking equipment 1, comprising: a cracking device 20, a gas separating and filtering device 30 and a cooling device 40 connected in sequence. The cracking device 20 includes a furnace body 201 and a heating device 202 , and the furnace body 201 is arranged on the upper part of the heating device 202 . The heating equipment 202 is composed of a furnace 2021 for placing fuel at intervals and a space 2022 for conducting heat; the furnace body 201 is heated by heat conduction through the heating equipment 202, instead of the steel plate of the furnace body 201 being in direct contact with or contacting, so as to prolong the service life of the equipment. The cooling device 40 includes a water pool 401 , a cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com