Integrated culture device of oleaginous microalgae

A technology for oil-producing microalgae and cultivation devices, which is applied in enzymology/microbiology devices, biochemical cleaning devices, bioreactors/fermenters for specific purposes, etc., can solve the problems of high energy consumption for cultivation and secondary pollution, etc. , to achieve the effect of improving culture efficiency, reducing energy consumption, and efficient oil production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

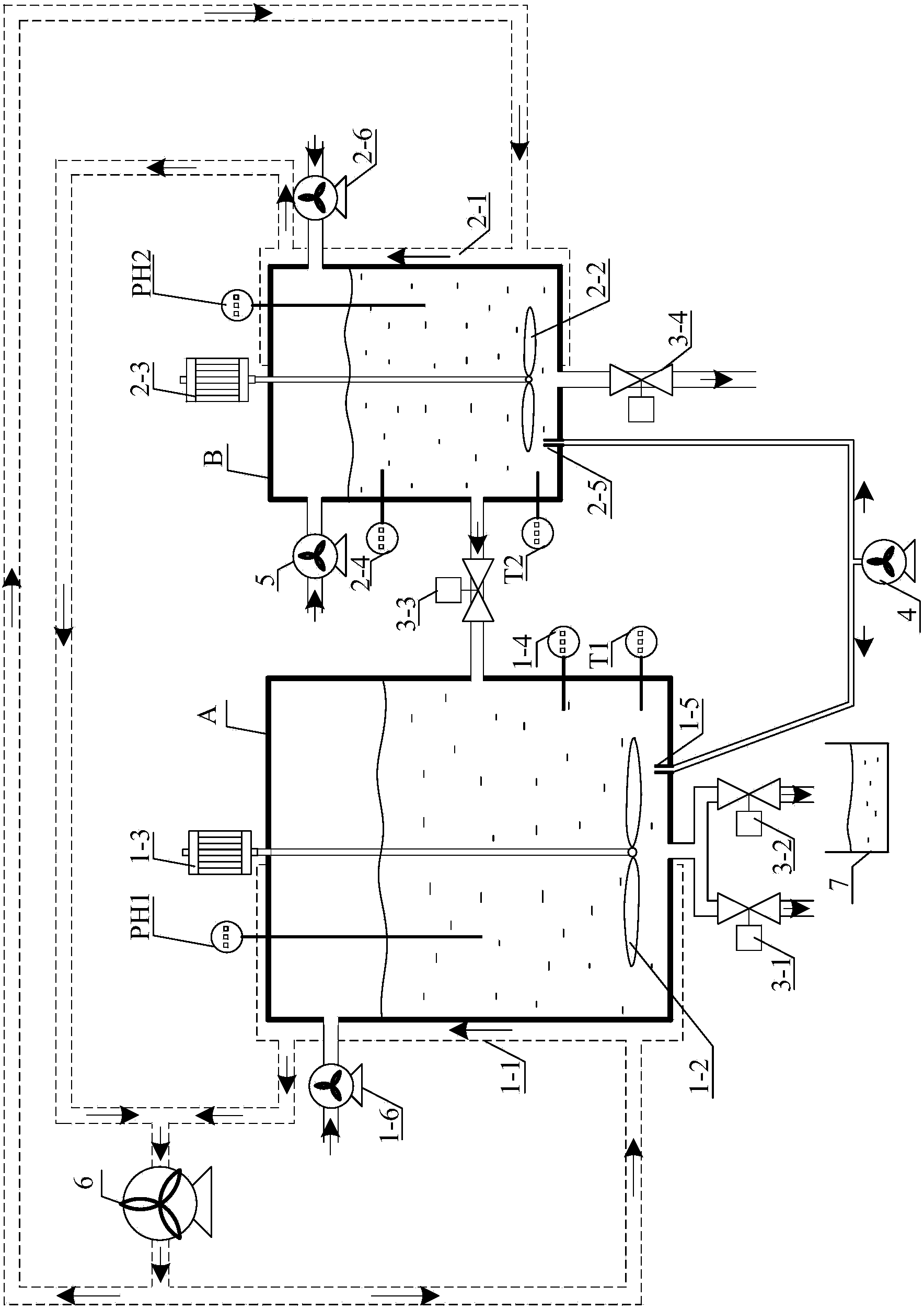

[0015] Specific implementation mode one: refer to figure 1 Specifically explain this embodiment, the integrated culture device for oleaginous microalgae described in this embodiment, it includes: culture reactor A, No. 1 water bath heating jacket 1-1, No. 1 agitator 1-2, No. 1 motor 1-3, No. 1 thermometer T1, No. 1 pH meter pH1, No. 1 dissolved oxygen meter 1-4, No. 1 aeration head 1-5, No. 1 feed pump 1-6, transparent reactor B, No. 2 water bath Heating jacket 2-1, No. 2 agitator 2-2, No. 2 motor 2-3, No. 2 thermometer T2, No. 2 pH meter pH2, No. 2 dissolved oxygen meter 2-4, No. 2 aerator head 2-5, No. 2 feed pump 2-6, No. 1 electric valve 3-1, No. 2 electric valve 3-2, No. 3 electric valve 3-3, No. 4 electric valve 3-4, aeration peristaltic pump 4, seed feeding Pump 5 and circulating heating water pump 6;

[0016] The side wall of the culture reactor A is provided with a medium feed port and a feed port, and the bottom of the culture reactor A is provided with a sampling ...

specific Embodiment approach 2

[0022] Specific embodiment 2: This embodiment is a further description of the integrated culture device for oleaginous microalgae described in specific embodiment 1. In this embodiment, it also includes: microalgae harvester 7; microalgae harvesting The device 7 is used to collect the microalgae sample flowing out from the other end of the No. 2 electric valve 3-2.

specific Embodiment approach 3

[0023] Specific embodiment three: This embodiment is a further description of the integrated culture device for oil-producing microalgae described in specific embodiment two. In this embodiment, it also includes: a visible light source; the light source is used to provide microalgae visible light.

[0024] Turn on the visible light source to let the light pass through the transparent reactor B, so that the microalgae seeds can fully contact with the light and carry out photosynthesis. Compared with reacting under natural light, adding a visible light source in this embodiment can make the reaction more sufficient, and it is suitable for conditions with weak natural light or no light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com