Biosynthesis method of ademetionine

A technique for the synthesis of adenosylmethionine and its synthesis method, which is applied in the field of biosynthesis of adenosylmethionine by beneficial engineering bacteria, which can solve the problems of high price and achieve the effects of reducing the cost of SAM synthesis, easy separation and operation, and large-scale synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

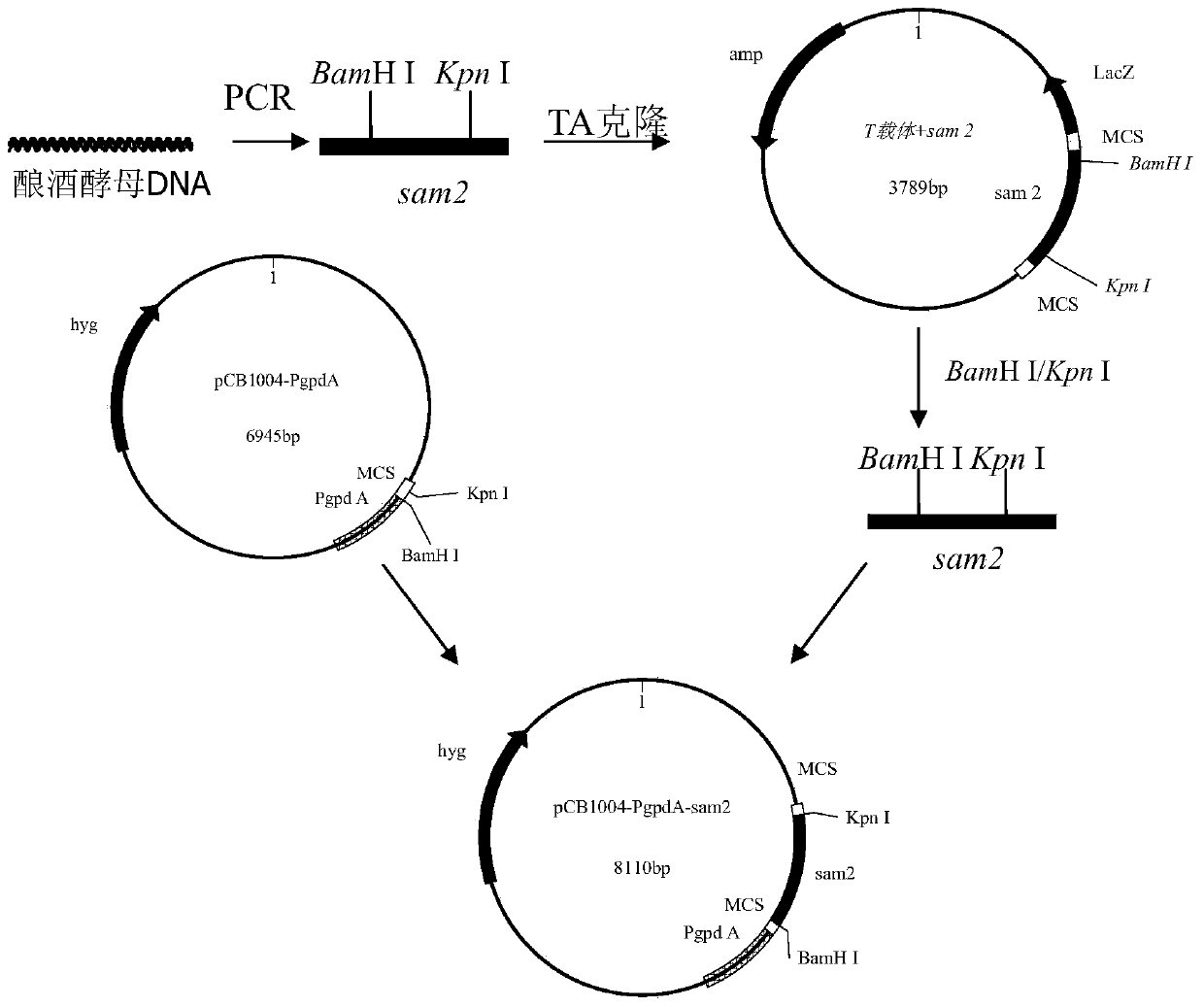

[0022] Example 1 Construction of engineering bacteria

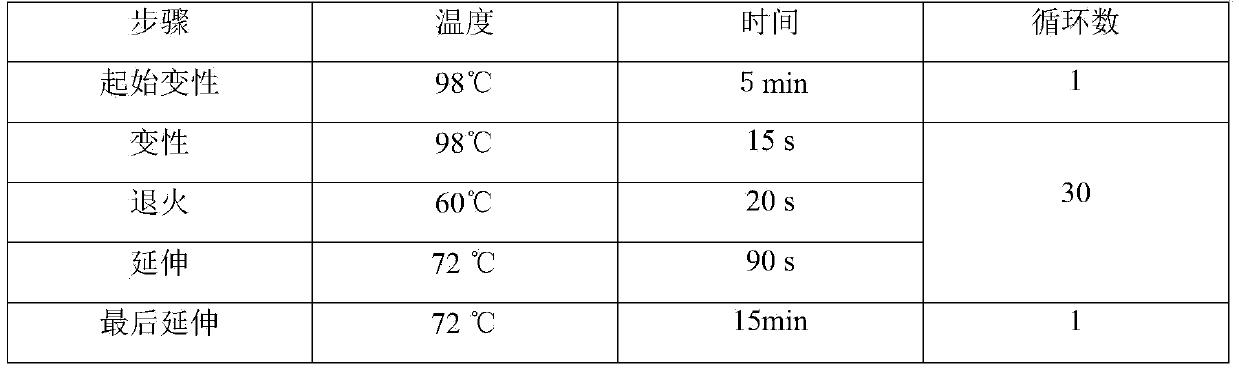

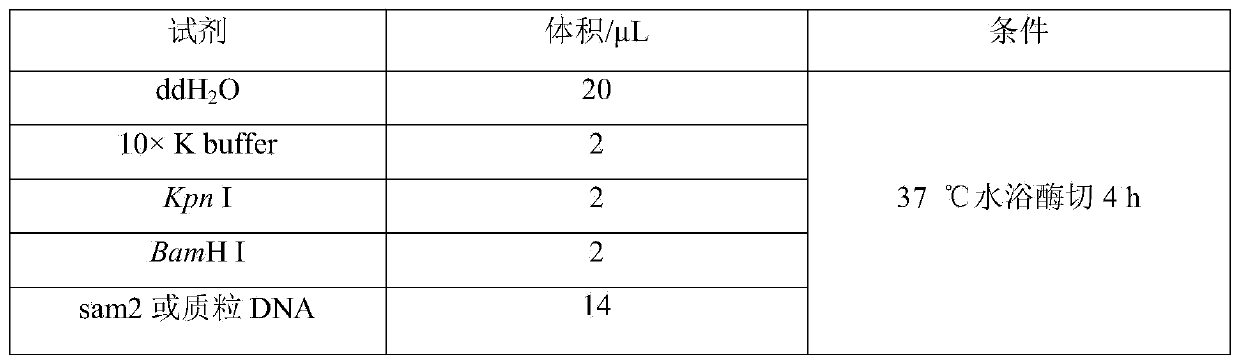

[0023] The specific construction method of SAM engineering bacteria containing Saccharomyces cerevisiae SAM synthetase gene 2 (sam2) used in the present invention is as follows (preparation of Actinomucor elegans protoplasts, cloning of target genes, restriction enzyme digestion verification, recombinant plasmid construction and transformation, protoplasts The specific conditions and methods of regeneration and transformant screening are detailed in the paper "Cloning and Expression of the Key Enzyme Gene APT1 for ATP Synthesis in Actinomucor elegans" (Zhu Jiarong, Yang Shanyan, Chen Lifen, etc. Food and Fermentation Industry, 2012, 38(6) ,43-47.):

[0024] 1. Experimental materials

[0025] Actinomucor elegans ZGB1 has been disclosed in patent CN102154117A.

[0026] E.coli DH5α was purchased from Shenggong Bioengineering (Shanghai) Co., Ltd.;

[0027] Saccharomyces cerevisiae 1964 (Saccharomyces cerevisiae1964) was purchased fro...

Example Embodiment

[0062] Example 2 SAM engineering bacteria culture collection and activation treatment

[0063] Liquid seed medium (g / L): glucose 20, peptone 10, yeast extract 5, NaCl5, solvent is water, pH 6.0-6.2; (slant medium plus agar 20).

[0064] Fermentation medium (g / L): glucose 40, yeast extract 3, corn steep liquor 10, NH 4 Cl3, MgSO 4 ·7H 2 O1, FeSO 4 ·7H 2 O0.2, K 2 HPO 4 ·3H 2 O3, the solvent is water, pH 6.0-6.5.

[0065] Inoculate the strains of SAM engineered bacteria in a slant medium (test tube or eggplant-shaped bottle), culture at 28-30°C for 3-4 days; wash the spores with an appropriate amount of liquid seed medium to obtain a spore suspension, and then use the spore suspension to Inoculate a 10% volume concentration inoculum into a 250mL Erlenmeyer flask containing the above-mentioned 100mL seed culture medium, 150-220r / min shaker, 28-30°C for 10-14h, to obtain a seed liquid; The inoculum is inoculated into a 500mL Erlenmeyer flask containing the above 300mL bacterial culture ...

Example Embodiment

[0067] Example 3 Transformation of SAM engineering bacteria into SAM

[0068] The activated bacteria are put into the following SAM reaction solution (g / L) in proportion: glucose 80, K 2 HPO 4 ·3H 2 O70, MgSO 4 ·7H 2 O4, adenine 3, L-methionine 4, active cell 80 (prepared by the method in Example 2), and the balance is water. The reaction was terminated at 33-37° C., 160r / min shaker for 10-14 hours, and liquid chromatography (the detection conditions and methods described in Example 1) determined that the yield of SAM in the reaction-terminated clear liquid was 1.0 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com