A box-type composite steel sheet pile, a vertical isolation engineering barrier and a water-stop curtain

A composite steel plate and steel sheet pile technology, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of large loss of bentonite, uneven hydration, and clumping of soil blocks, so as to reduce the cost of the project and ensure the overall Homogeneity, effect of improving impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

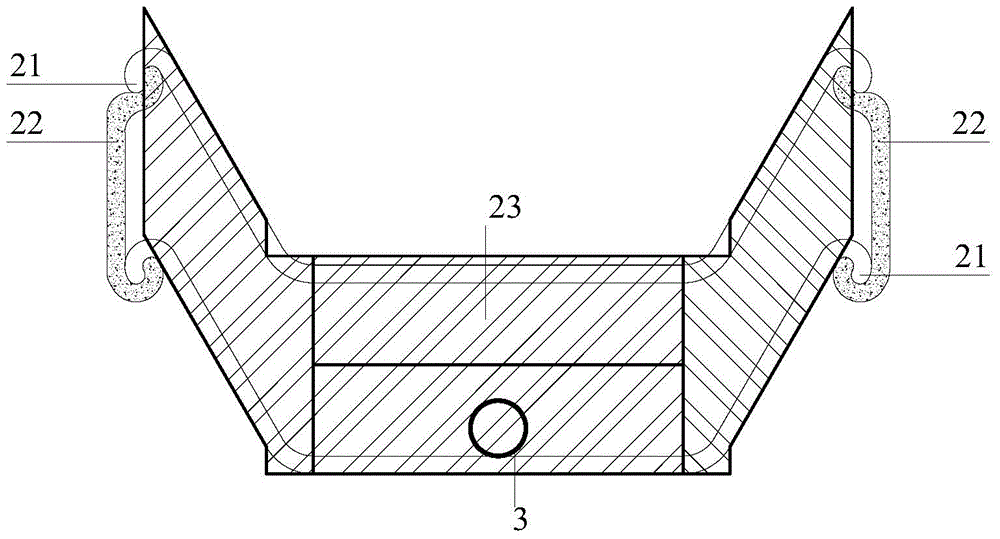

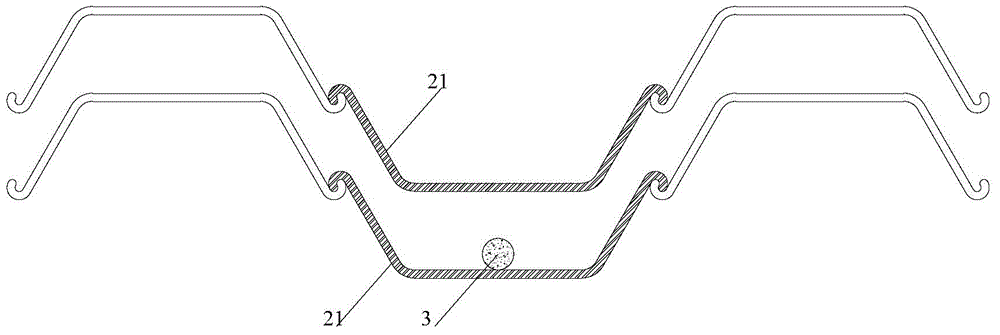

[0034] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0035] The box-type composite steel sheet pile mentioned in the present invention is composed of NSP-IIIw hot-rolled U-shaped steel sheet piles in Larsen steel sheet piles, and the type of hot-rolled U-shaped steel sheet piles can also be changed according to actual working conditions and construction equipment requirements; pollution The types of pollutants include heavy metal pollutants, organic pollutants, and heavy metal-organic compound pollutants. The U-shaped steel sheet pile driving equipment 41 mentioned in the present invention, the U-shaped steel sheet pile pulling equipment 42, and the pumping equipment 43 are all common construction equipment for geotechnical engineering construction, which can ensure the operability and promotion of the present invention .

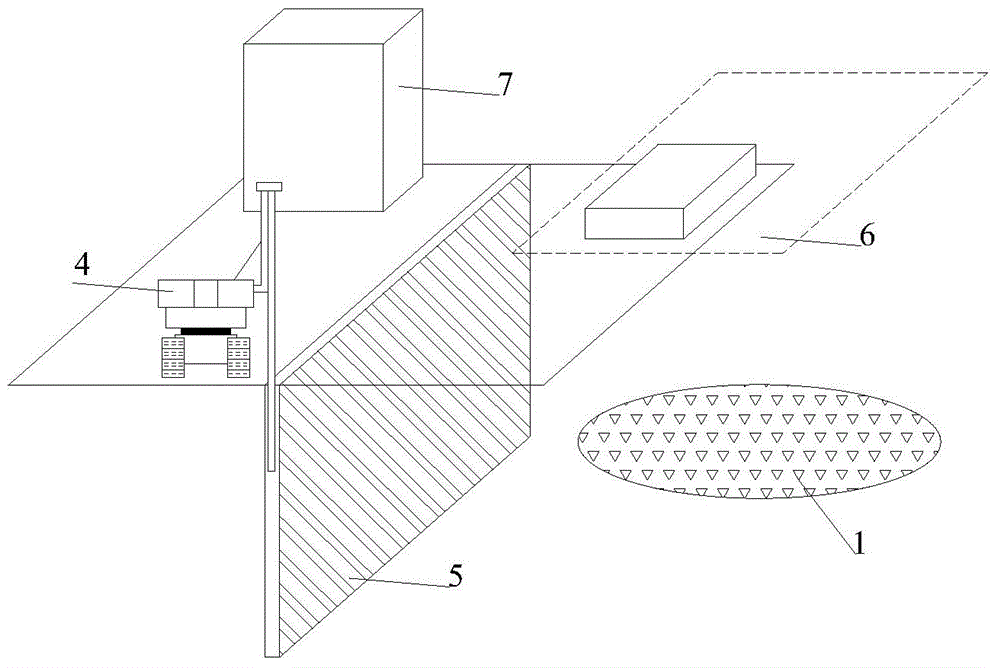

[0036] figure 1It shows that the pollution source 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com