Piling machine

A technology of pile driver and vertical frame, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc. It can solve the problems of high height and weight of the whole machine, complex structure, inconvenient operation and transition, etc., so as to facilitate operation and transition , adapt to a wide range of effects, easy to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

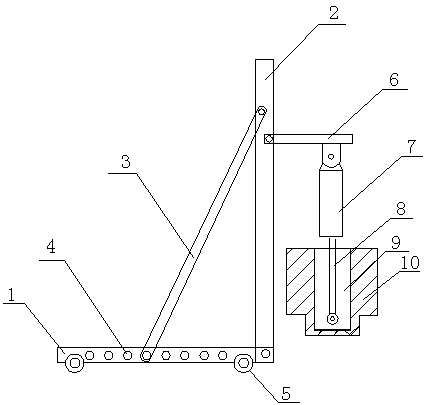

[0013] Such as figure 1 As shown, a pile driver comprises a base 1, a stand 2 positioned on the base 1, a support rod 3 and a hammer body 10, the base 1 is hinged with the stand 2, and the two ends of the support rod 3 are respectively connected to the base 1, The stand 2 is connected, the base is provided with a connection hole 4, the fixed plate 6 is fixedly connected with the stand 2, the hydraulic lifting cylinder 7 is fixedly connected with the fixed plate 6, and the hammer body 10 is provided with a hole 9 which can accommodate the hydraulic lifting cylinder 7 , the lower piston rod 8 of the hydraulic lifting cylinder 7 stretches into the hole 9 of the hammer body 10 and is fixedly connected with the bottom of the hammer body 10 . The base 1 is also symmetrically and detachably provided with r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com