Multistage pressurized high pressure steam hot water generator

A high-pressure steam generator technology, applied in the field of multi-stage pressurized high-pressure steam hot water generators, can solve the problems of large heat loss, low energy utilization rate, high energy consumption, etc., to reduce hot water energy consumption, Improve kinetic energy utilization and improve hot water efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in combination with specific embodiments.

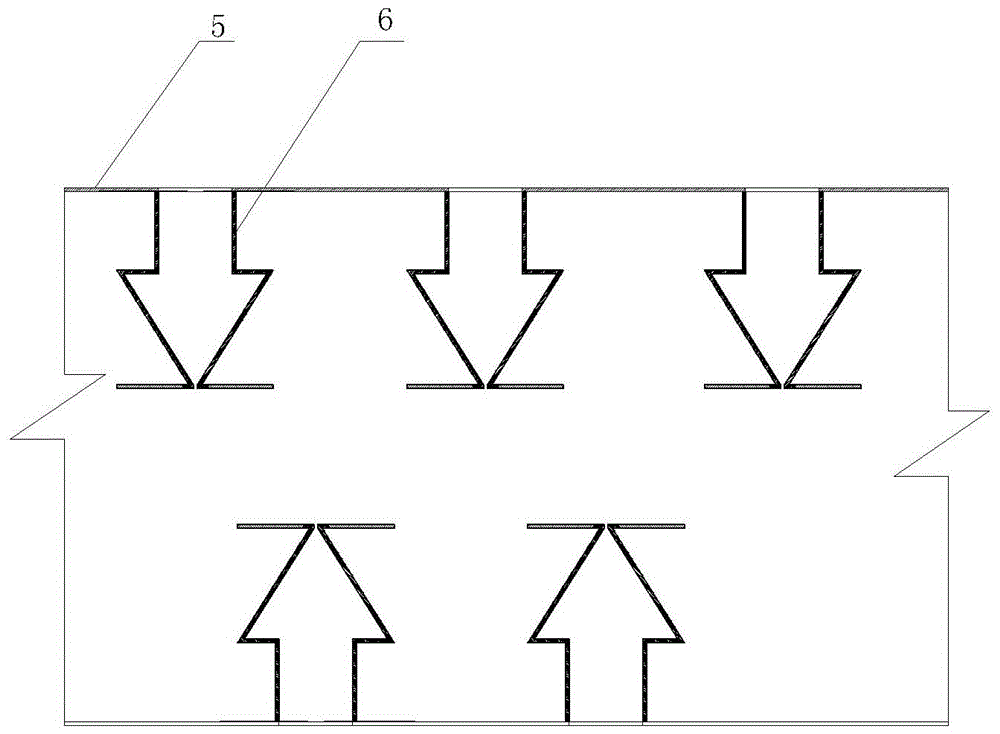

[0021] The present invention relates to a multi-stage pressurized high-pressure steam hot water generator, comprising a horizontal cylindrical hot water generator tank body 5, one end is a water inlet, the other end is a water outlet, the hot water generator tank body 5 A number of nozzles 6 connected to the exhaust port of the steam boiler are arranged in a row at the top and bottom of the boiler, and the nozzles 6 are opposite and staggered.

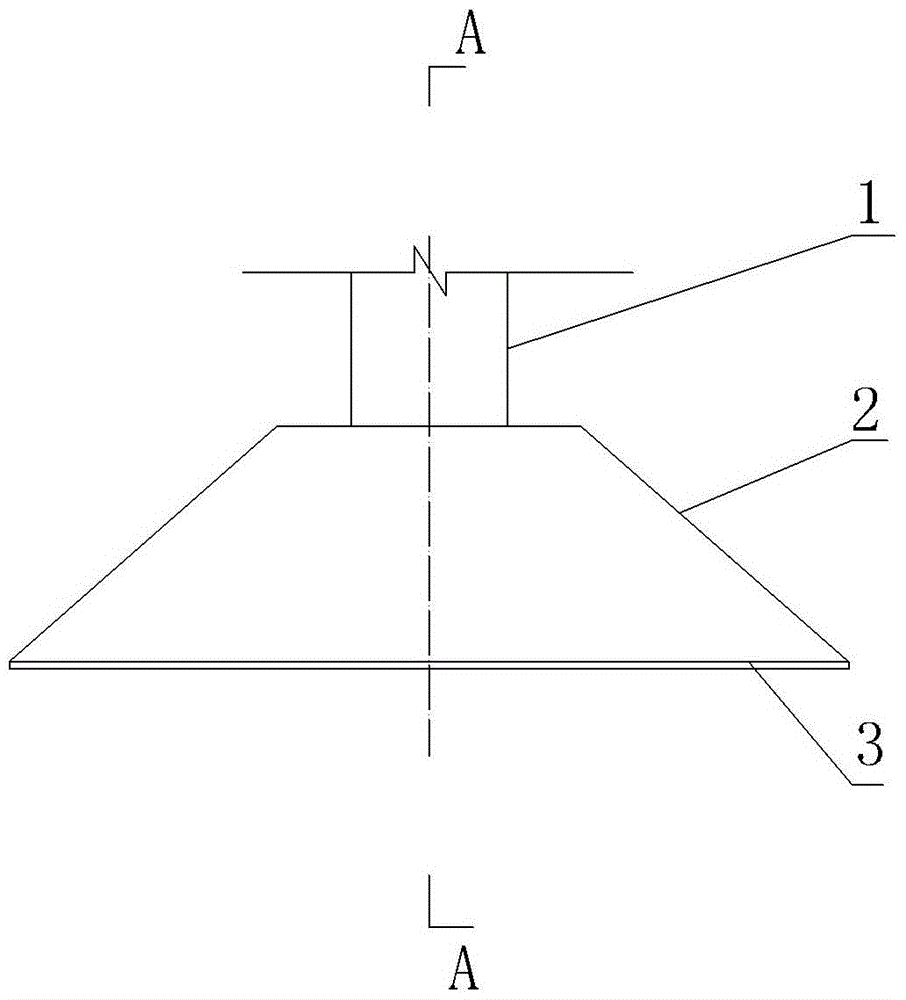

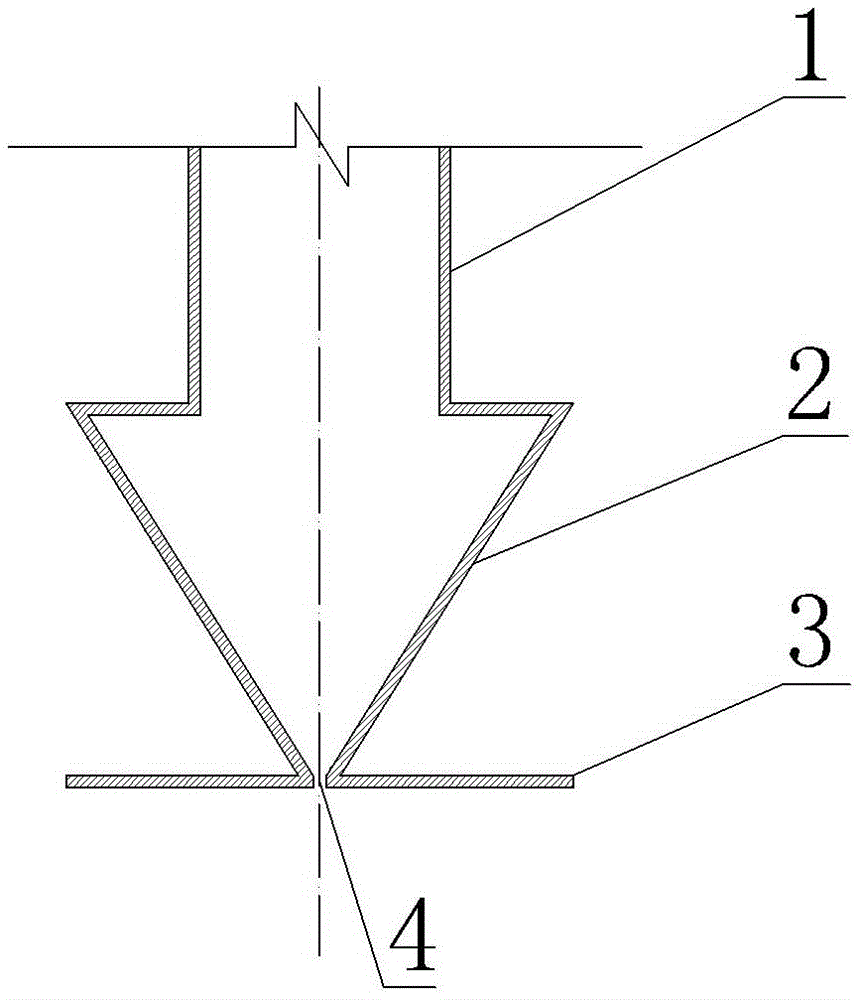

[0022] The nozzle 6 is provided with a circular tube-shaped air inlet 1 for connecting with the exhaust port of the steam boiler, the diameter of the air inlet 1 matches the diameter of the corresponding steam boiler exhaust port, and is connected by a flange. The other end of the air inlet 1 is connected to the air trap 2. The air trapping groove 2 is composed of the top surface and four sides welded, and is made of ordinary rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com