Vertical flue composite phase change heat exchanger

A technology of vertical flue and composite phase change, which is applied in the direction of indirect heat exchangers, lighting and heating equipment, etc., can solve the problems that composite phase change heat exchangers cannot be applied to vertical flue engineering applications, and expand the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

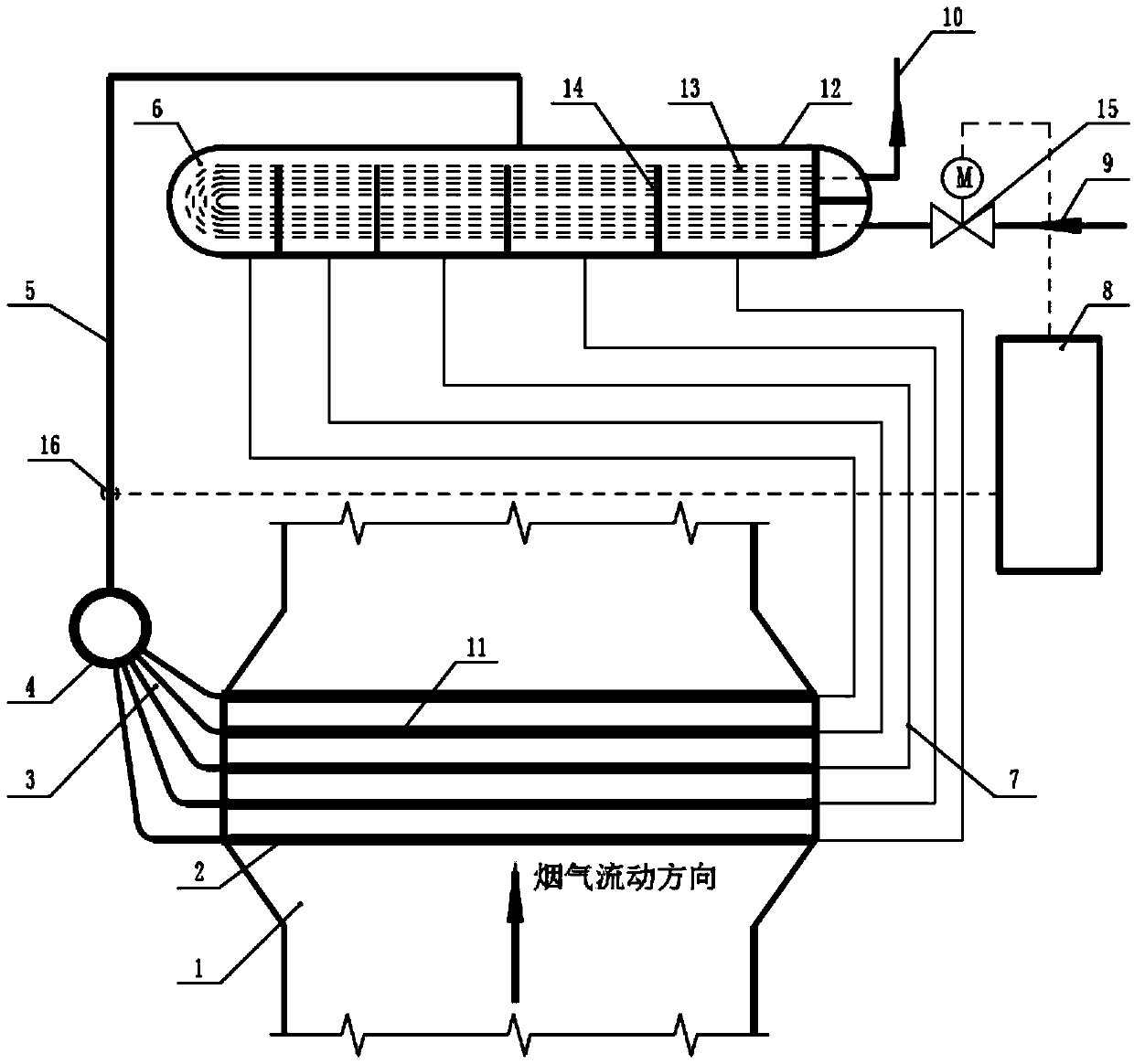

[0016] like figure 1 As shown, this embodiment includes: evaporation section 2, steam pipeline 5, condensation section 6, condensate water pipeline 7 and control system 8, wherein: evaporation section 2 is arranged in vertical flue 1, and the upper end of evaporation section 2 is connected with steam The lower end of the pipeline 5 is connected, the upper end of the condensation section 6 is connected with the upper end of the steam pipeline 5, one end of the condensation water pipeline 7 is connected with the side of the evaporation section 2, and the other end is connected with the lower end of the condensation section 6, and the control system 8 is respectively connected with the steam pipeline 5 links to each other with condensation section 6;

[0017] The condensing section 6 includes: a housing 12, several steam-water heat exchange tubes 13 and several baffles 14, wherein: several steam-water heat exchange tubes 13 are arranged horizontally and side by side inside the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com