Heat pipe liquid absorbing core capillary flow measuring method and device based on infrared image observation

A technology of infrared thermal imaging and flow measurement, applied in measuring devices, devices using optical methods, liquid/fluid solid measurement, etc., to achieve high measurement accuracy, low error, and simple experimental devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

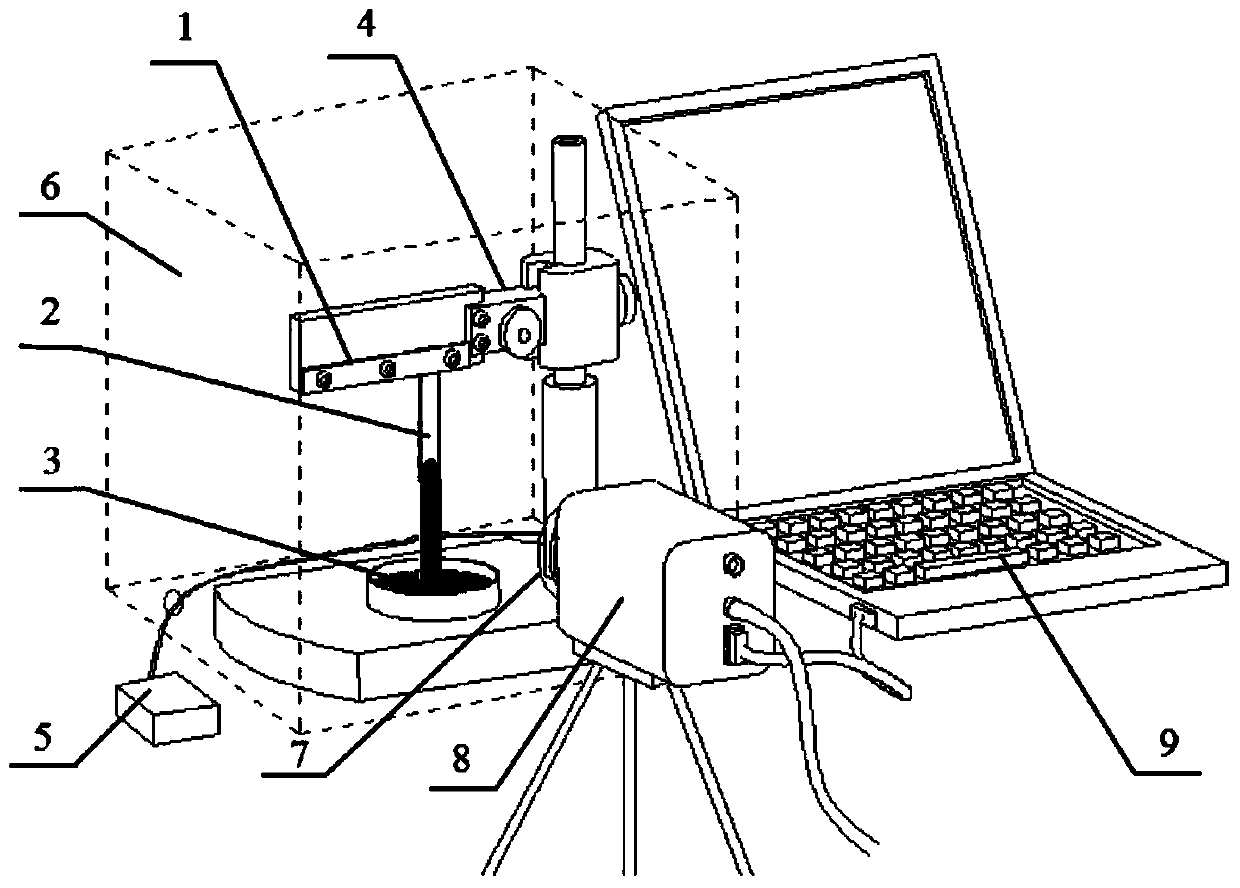

[0037] Such as figure 1 As shown, a capillary flow measurement device of a heat pipe liquid-absorbing core based on infrared thermal image observation includes a liquid-absorbing core fixing assembly 1, a working medium container 3, a moving adjustment assembly 4, an adjustment controller 5, a glass cover 6, and an infrared thermal image Instrument 8, data acquisition computer 9 and rack;

[0038] The liquid-absorbing core fixing assembly 1, liquid-absorbing core 2, working medium container 3, moving adjustment assembly 4 and frame are located in the glass cover 6; the liquid-absorbing core 2 is fixed and vertically attached to the liquid-absorbing core fixing assembly 1; The liquid core fixing component 1 is fixedly connected to the mobile adjustment component 4, and the mobile adjustment component 4 is slidably connected to the frame; the adjustment controller 5 is located outside the glass cover 6, and the adjustment controller 5 can control the mobile adjustment component ...

Embodiment 2

[0054] The difference between this embodiment and embodiment 1 is that the liquid-absorbent core 2 is placed horizontally instead of vertically, and the capillary flow length and flow rate of the liquid-absorbent core can be measured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com