Bending insensitive single mode fiber and production technology thereof

A bend-insensitive, single-mode fiber technology, applied in clad fibers, multi-layer core/clad fibers, graded-index core/clad fibers, etc., can solve problems such as complex processes and reduce The effect of mode field diameter, avoiding optical loss, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

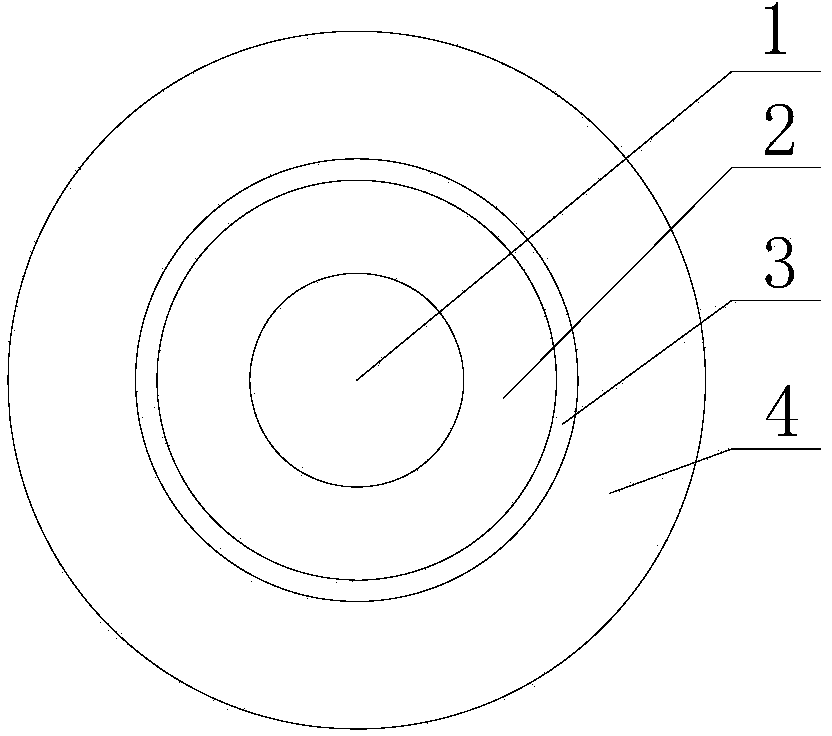

[0053] Such as figure 1 As shown, the bend-insensitive single-mode optical fiber includes a core 1 and a cladding, and the cladding includes an inner cladding 2 coated on the core 1 and a sunken cladding coated on the inner cladding 2 3. The outer cladding layer 4 covering the sunken cladding layer 3 .

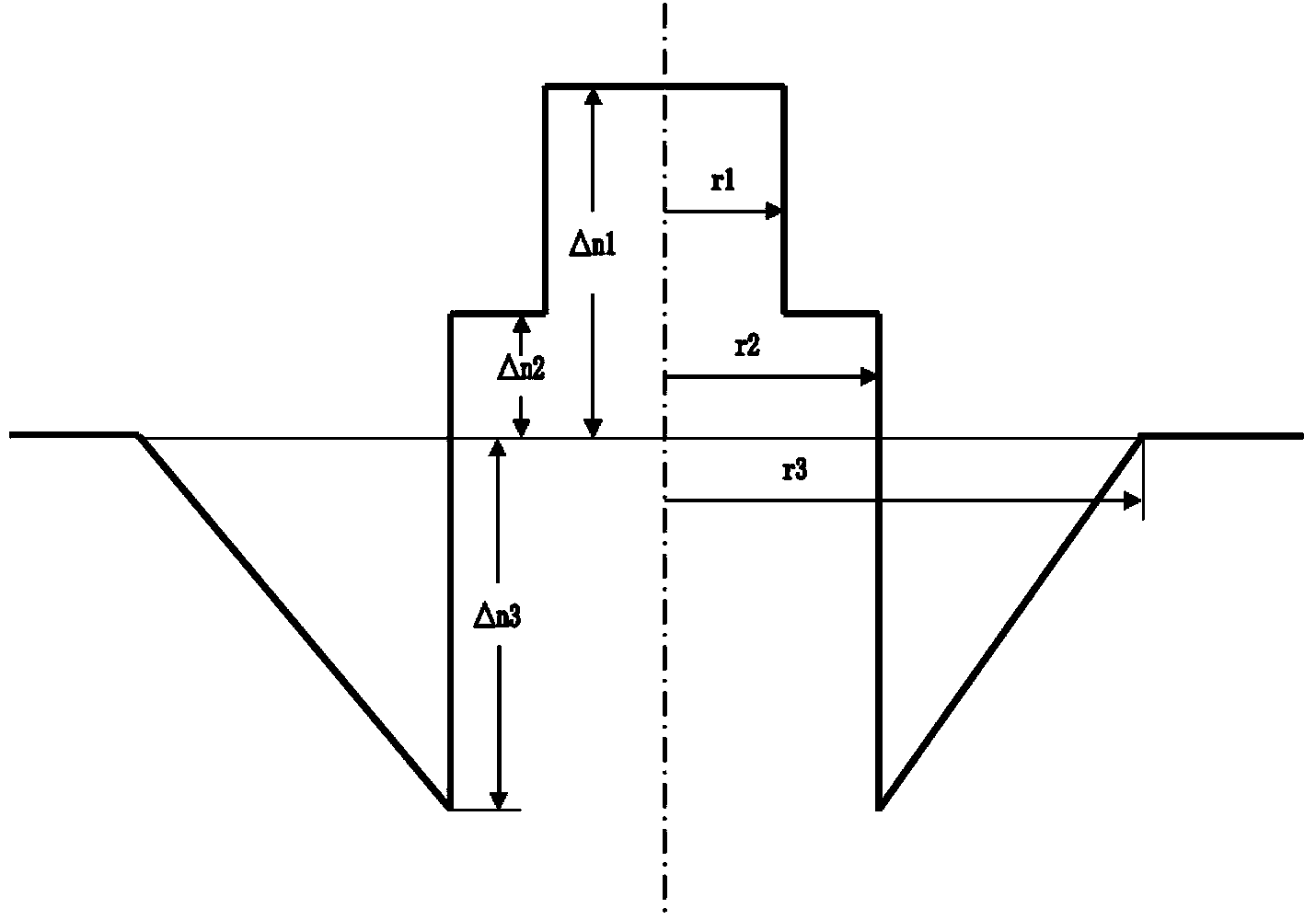

[0054] Such as figure 2 As shown, the refractive index of the core 1 is n 1 , the refractive index of the inner cladding 2 is n 2 , the refractive index of the depressed cladding 3 is n 4 , the refractive index of the outer cladding n 3 .The refractive index n 1 As the radius of the core 1 increases and remains constant, the refractive index n 2 As the radius of the inner cladding 2 increases and remains constant, the refractive index n 3 As the radius of the outer cladding increases and remains constant, the refractive index n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com