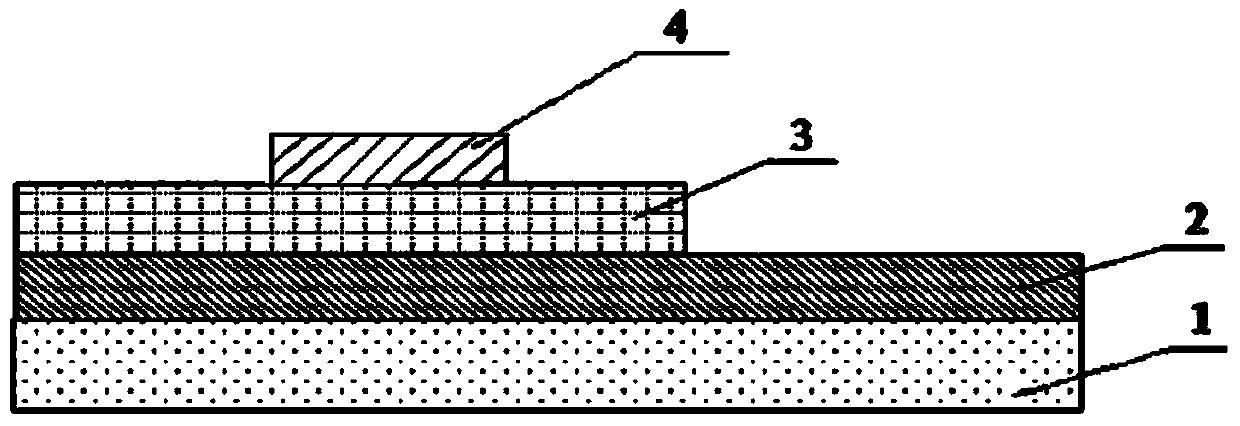

Full-permeable bismuth-based pyrochlore thin film voltage-controlled varactor and manufacturing method thereof

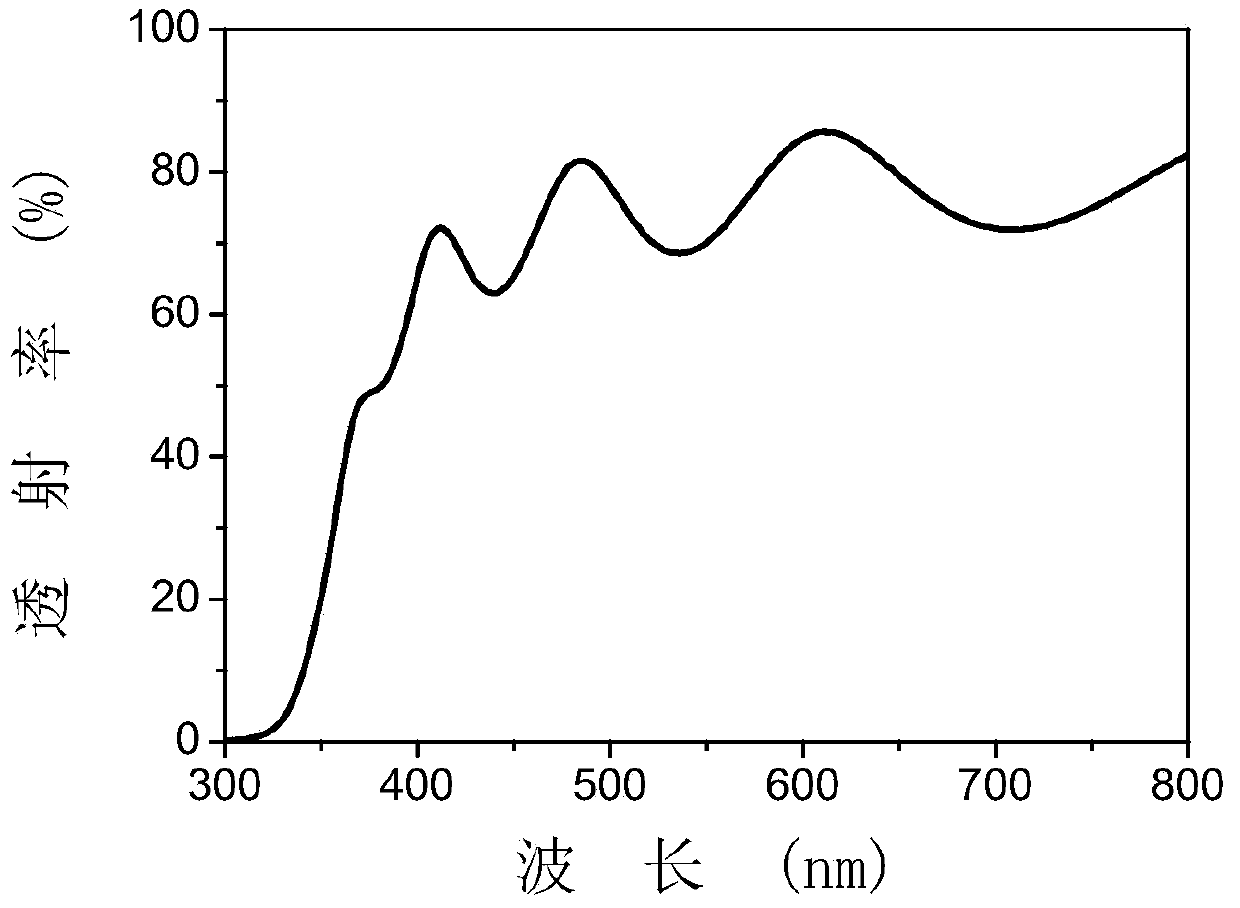

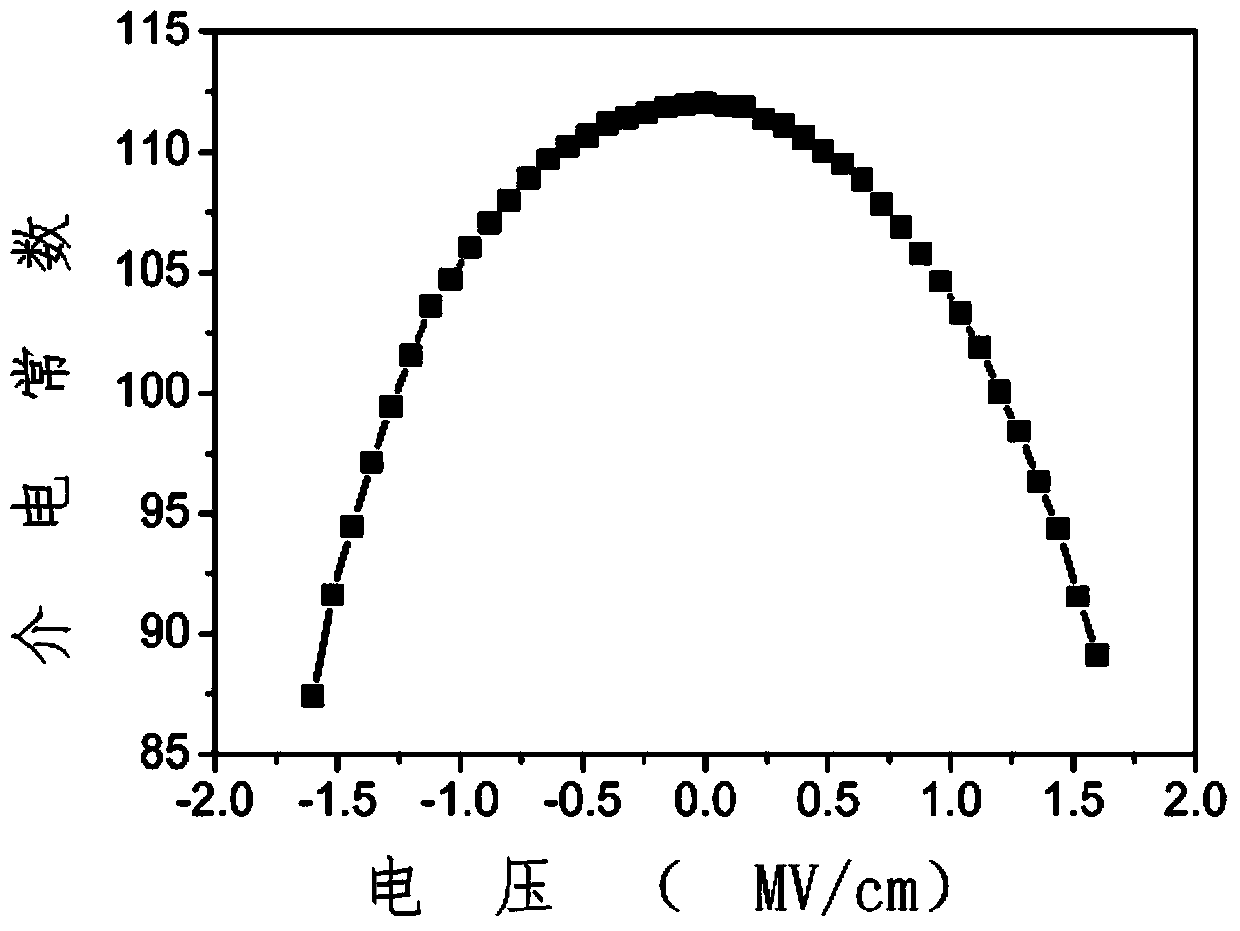

A technology of pyrochlore and varactor, applied in the field of fully transparent bismuth-based pyrochlore thin-film voltage-controlled varactor and its preparation, achieving the effects of high transparency, good device stability, and moderate tuning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of Bi by solid-state sintering method 1.5 Mg 1.0 Nb 1.5 o 7 target

[0035] Press Bi with electronic balance 1.5 Mg 1.0 Nb 1.5 o 7 The stoichiometric ratio of the corresponding elements weighs Bi with a purity of 99%. 2 o 3 , MgO and Nb 2 o 5 , after being fully mixed, pressed and formed under a pressure of 30Mpa, and finally placed in a box-type electric furnace and gradually heated to 1150°C, and kept for 10 hours.

[0036] (2) The AZO conductive glass substrate with AZO, that is, the Al-doped ZnO film as the bottom electrode layer, is ultrasonically cleaned with acetone, ethanol and deionized water, and cleaned with N 2 Blow dry and place on magnetron sputtering sample stage.

[0037](3) Pump the background vacuum of the magnetron sputtering system to 6.0×10 -6 Torr, then heat the AZO conductive glass substrate to 500 °C.

[0038] (4) with high purity (99.99%) Ar and O 2 As the sputtering gas, the flow ratio of argon and oxygen was 17:3...

Embodiment 2

[0045] (1) Preparation of Bi by solid-state sintering method 1.5 Zn 1.0 Nb 1.5 o 7 target

[0046] Press Bi with electronic balance 1.5 Zn 1.0 Nb 1.5 o 7 The stoichiometric ratio of the corresponding elements weighs Bi with a purity of 99%. 2 o 3 , ZnO and Nb 2 o 5 , after being fully mixed, pressed and formed under a pressure of 30Mpa, and finally placed in a box-type electric furnace and gradually heated to 1050°C, and kept for 10 hours.

[0047] (2) The AZO conductive glass substrate with AZO, that is, the Al-doped ZnO film as the bottom electrode layer, is ultrasonically cleaned with acetone, ethanol and deionized water, and cleaned with N 2 Blow dry and place on magnetron sputtering sample stage.

[0048] (3) Pump the background vacuum of the magnetron sputtering system to 7.0×10 -6 Torr, then heat the AZO conductive glass substrate to 500 °C.

[0049] (4) with high purity (99.99%) Ar and O 2 As the sputtering gas, the flow ratio of argon and oxygen was 17:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap