A phase change cooling device and its manufacturing method

A technology of a heat dissipation device and a manufacturing method, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems that the heat dissipation method is difficult to function, cannot meet the working requirements of the equipment, and the heat capacity is small, so as to achieve a clear manufacturing process and strong designability. , the effect of large heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

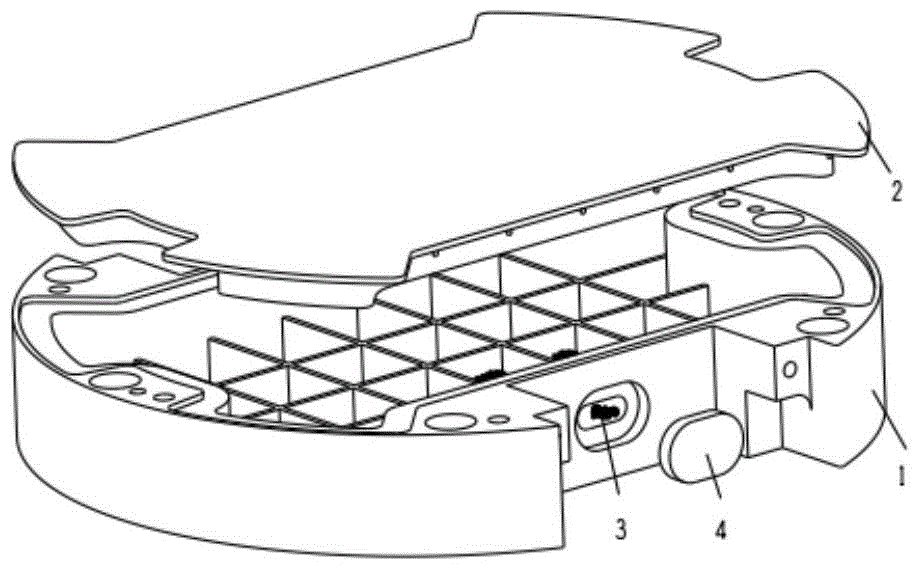

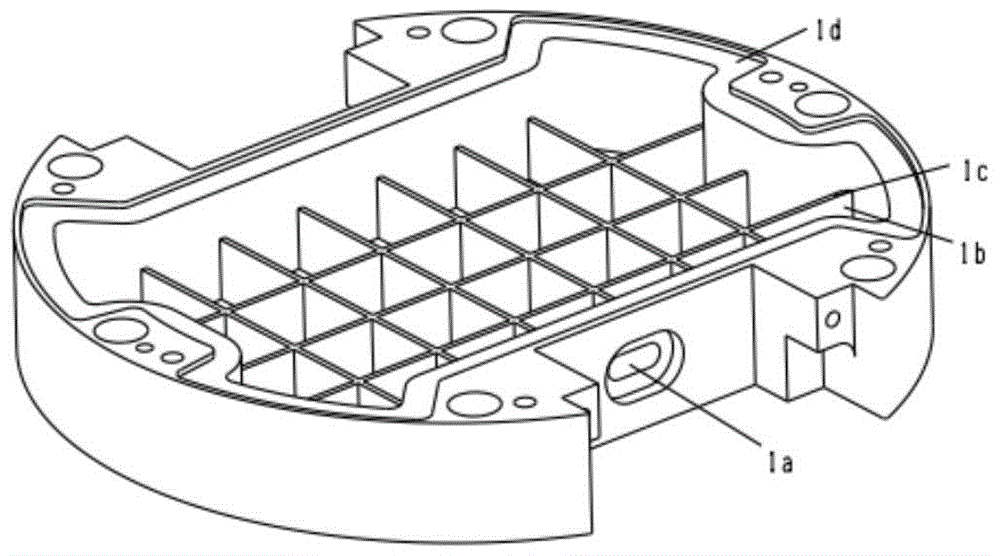

[0033] The phase change heat dissipation device designed in this embodiment is composed of a base body, a cover plate, a phase change material and an encapsulation block. The base body is a shell with slots on one side. The size of the base body of the phase change heat dissipation device is 154mm (length) × 204mm (width) × 25mm (height). In the region, the thickness of the thermally conductive ribs is 1mm, the spacing is 11mm, and the height is 15mm, and the height of the thermally conductive ribs is lower than that of the periphery of the substrate. The heat conduction reinforcing rib can not only improve the heat conduction performance between the base body and the cover plate, but also enhance the expansion and bending resistance mechanical properties of the shell.

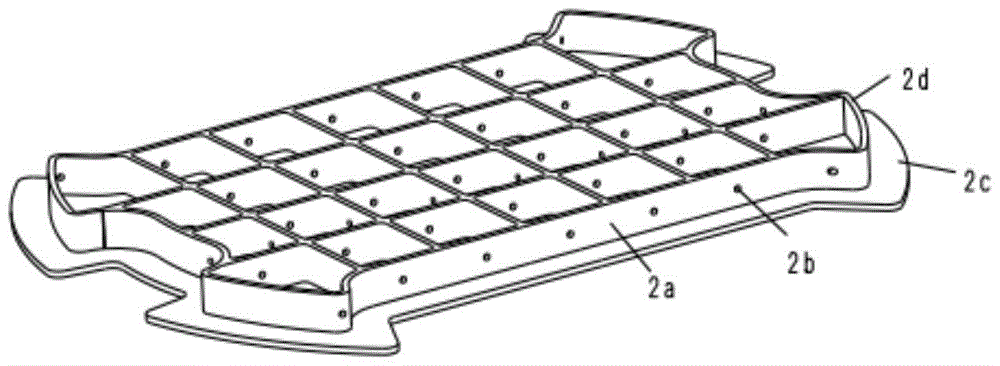

[0034] The cover plate is a flat plate with reinforcing ribs on one side, the thickness of the cover plate is 1.5mm, the thickness of the reinforcing ribs on it is 1mm, the height is 7mm, and the spacing is 11...

Embodiment 2

[0051] The phase change heat dissipation device designed in this embodiment is composed of a base body, a cover plate, a phase change material and an encapsulation block. The base body is a shell with grooves on one side. The size of the base body of the phase change heat sink is φ120mm×20mm (height). The groove is provided with thermally conductive reinforcing ribs, which divide the inside of the shell into multiple sub-regions, wherein the thickness of the thermally conductive reinforcing ribs is 1.5mm, the spacing is 15mm, the height is 13mm, and the height of the heat conduction rib is lower than the peripheral height of the base. The heat conduction reinforcing rib can not only improve the heat conduction performance between the base body and the cover plate, but also enhance the expansion and bending resistance mechanical properties of the shell.

[0052]The cover plate is a flat plate with reinforcing ribs on one side, the thickness of the cover plate is 1.5mm, the thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com