Rotary oscillating cutting tools for machine tools

A cutting tool and machine tool technology, applied in the field of rotary oscillating cutting tools, can solve problems such as high driving force, and achieve the effects of reducing chatter, improving rigidity, and improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

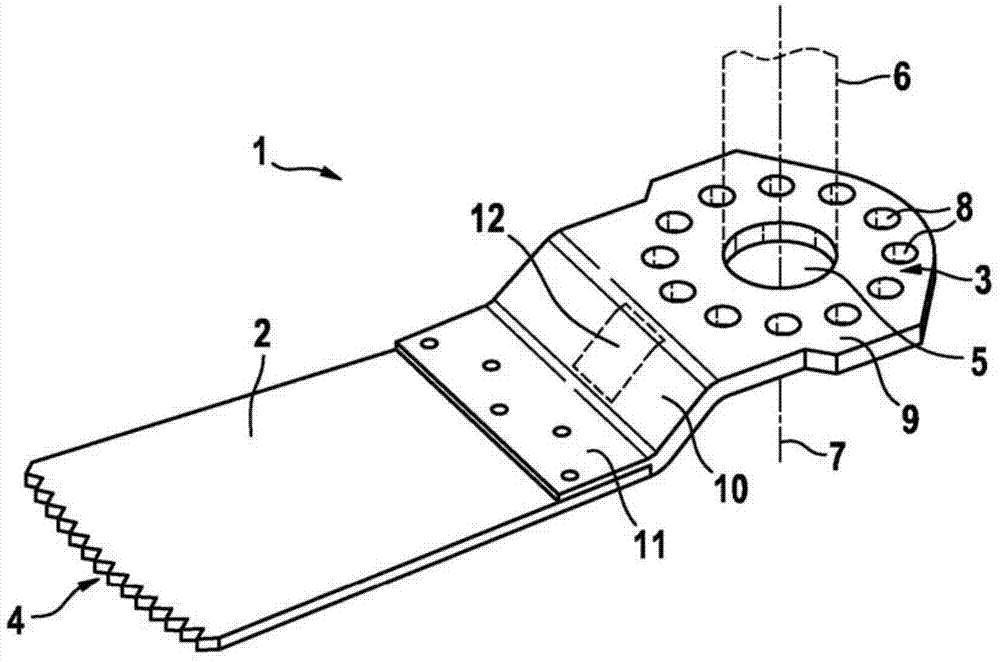

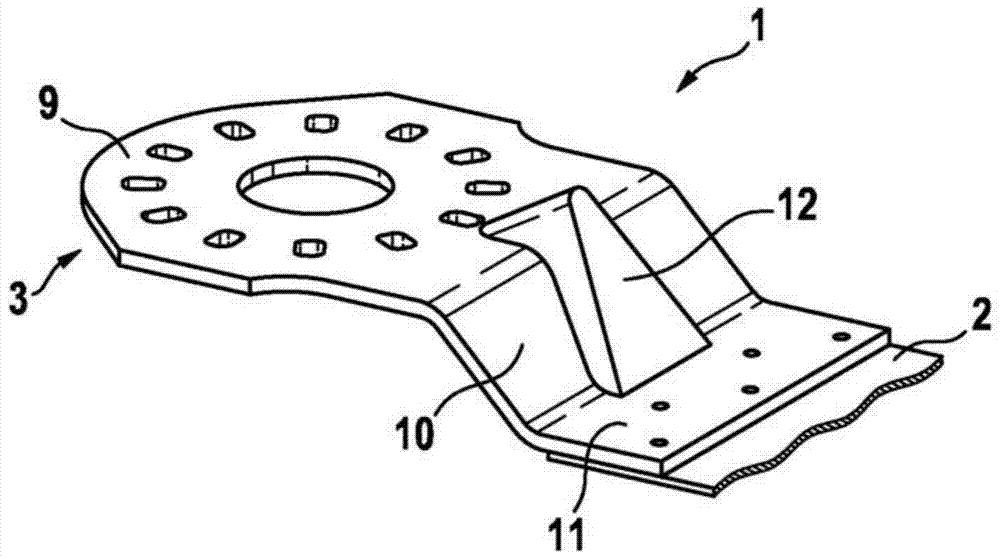

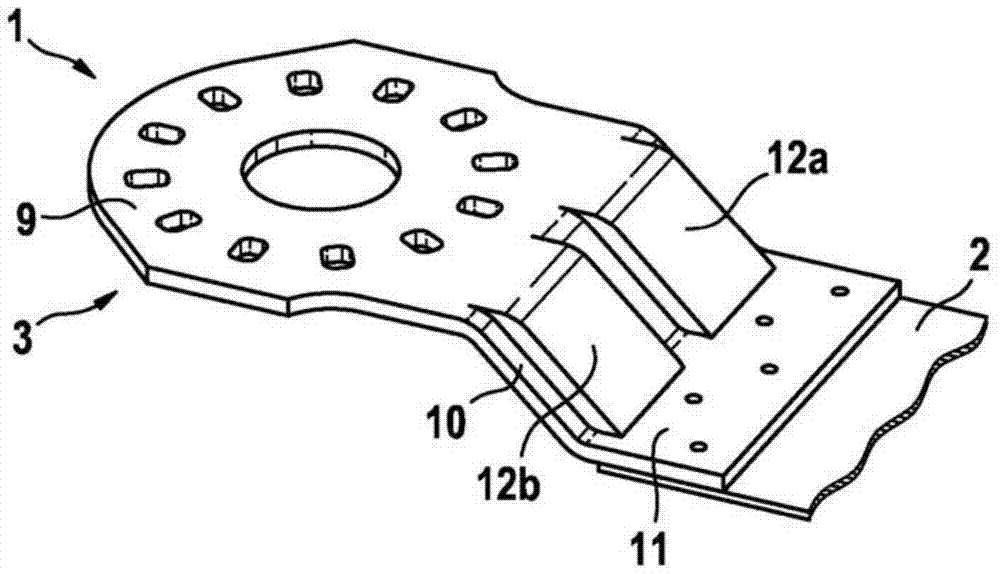

[0036] All figures show a rotary oscillating cutting tool in the form of a rotary oscillating saw blade or plunger saw blade for a power tool.

[0037] exist figure 1 The rotary oscillating cutting tool 1 shown in FIG. 2 comprises an at least substantially rectangular or arcuate stem piece 2 and a bent holder 3 connected to the stem piece 2 . On the free end side facing away from the holder 3 , the backbone piece 2 is provided with a cutting edge 4 with cutting teeth. The holder 3 comprises a shaft receptacle section 9 which has a fixed receptacle 5 for receiving a tool shaft 6 of a machine tool which performs a rotationally oscillating movement about the axis of rotation 7 . The fastening to the tool shaft 6 takes place by means of a detent opening 8 which is formed annularly around the central fastening recess 5 in the shaft receiving section 9 .

[0038] Furthermore, the holder 3 comprises a transition section 10 and a connecting section 11 via which the connection to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com