Fluid discharge vibration damping strips for acoustic protection of aircraft turbomachine fan casing

一种声学保护、振动阻尼的技术,应用在用于弹性流体的泵送装置的部件、飞机上动力装置、飞机零件等方向,能够解决不能完全令人满意等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

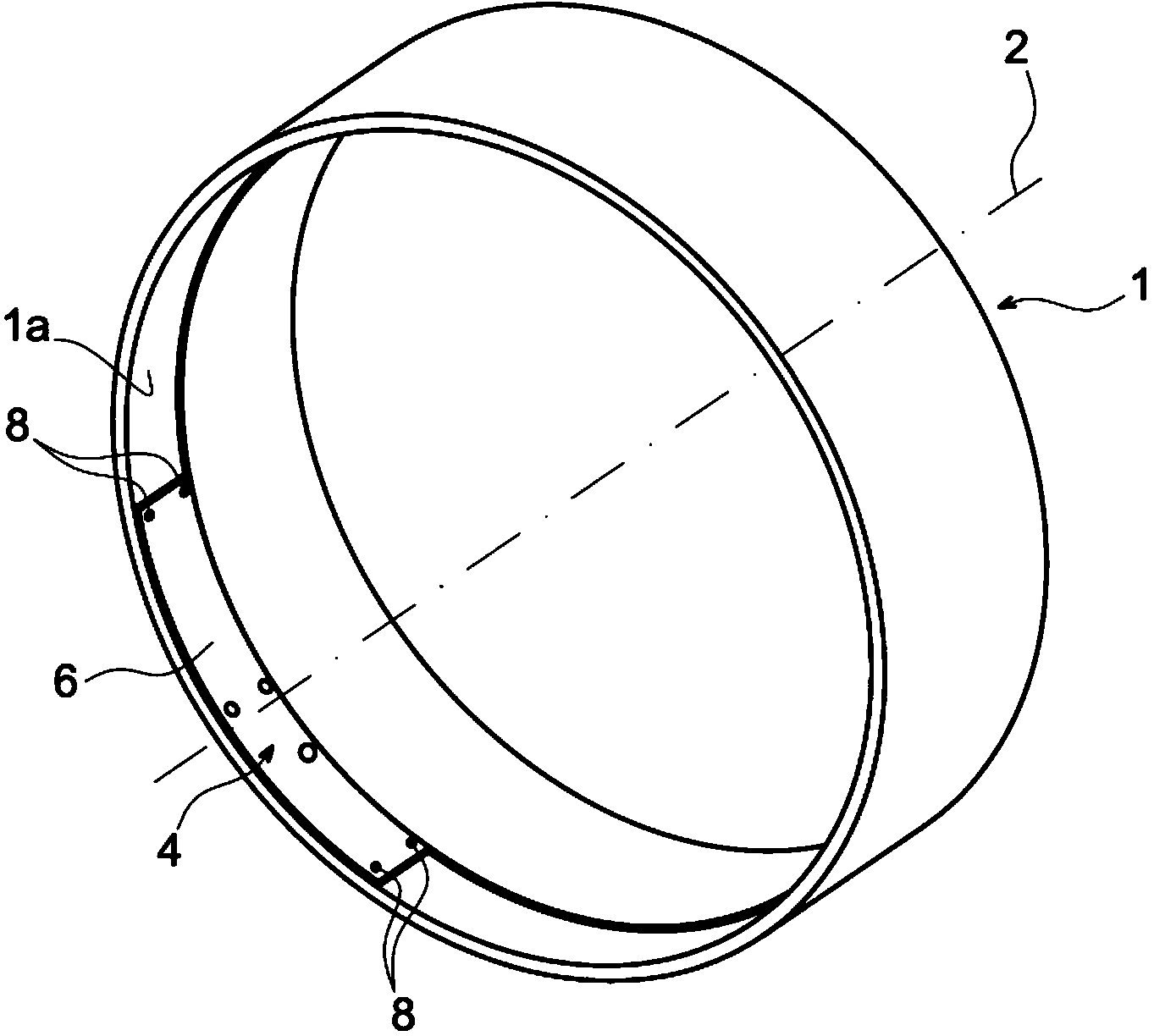

[0036] First reference figure 1 , Which represents the fan cover 1, which is defined as the main part of the front part of the aircraft turbojet aircraft engine. Preferably, the aircraft turbojet aircraft engine is of a dual-flow dual-rotor type.

[0037] The cover assumes a conventional ferrule shape with a longitudinal axis 2 that coincides with the longitudinal axis of the turbojet engine assembly.

[0038] At its upstream end, the inner surface 1a of the cover 1a is equipped with a plurality of acoustic protection devices 4, figure 1 Only one of them is shown in.

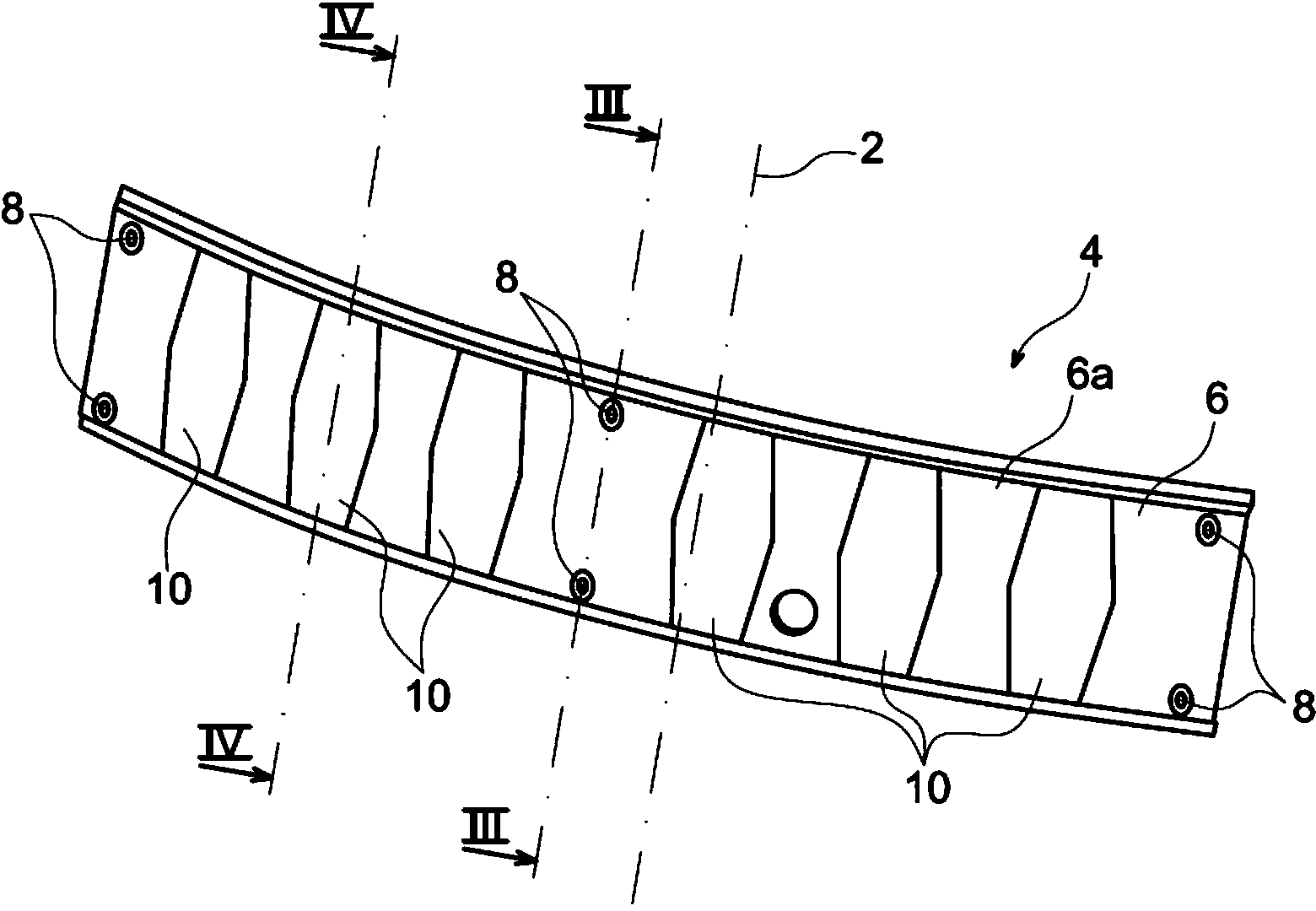

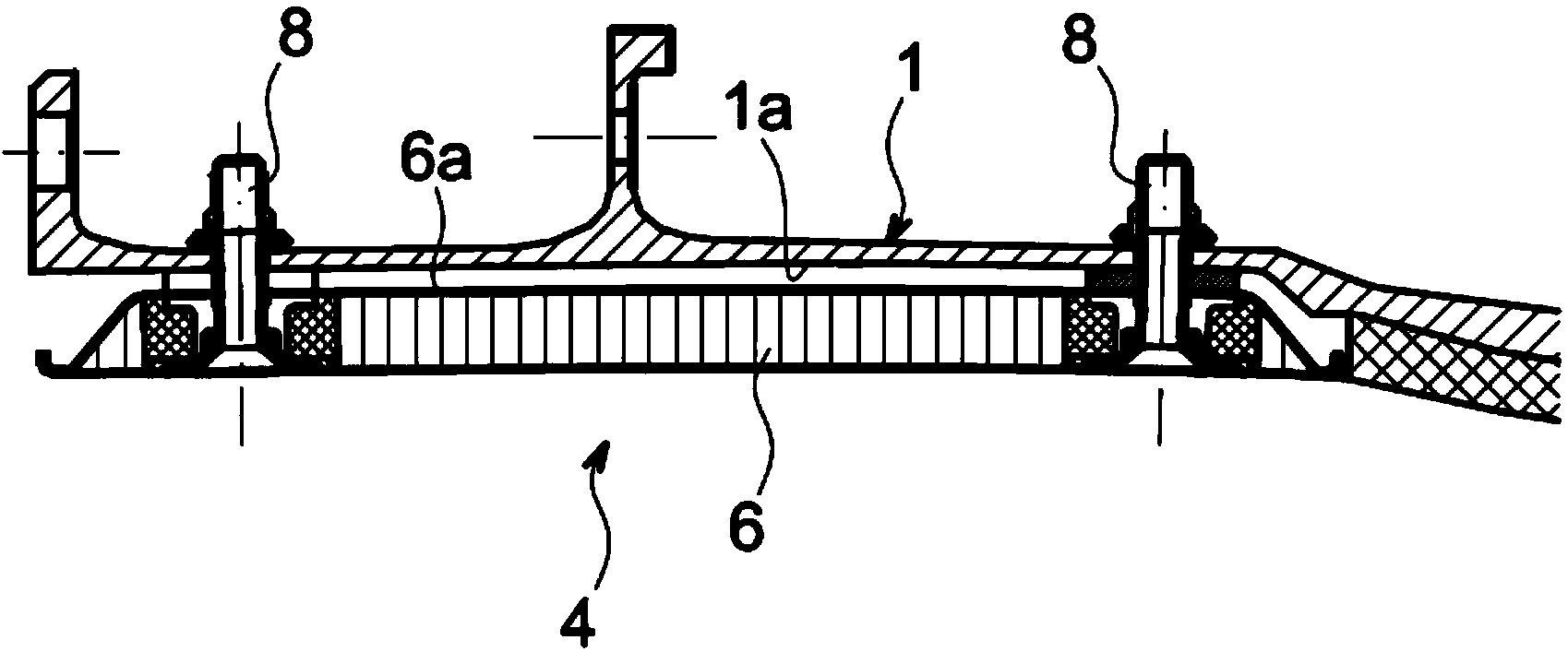

[0039] The device 4 includes an acoustic protection plate 6 that forms a ferrule sector part centered on the same central axis as the longitudinal axis 4. When all the protection devices are installed on the cover, its plates 6 which are continuous with each other in the circumferential direction together form an internal acoustic protection ring.

[0040] Preferably, the plate 6 is assembled on the cover by screws, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com