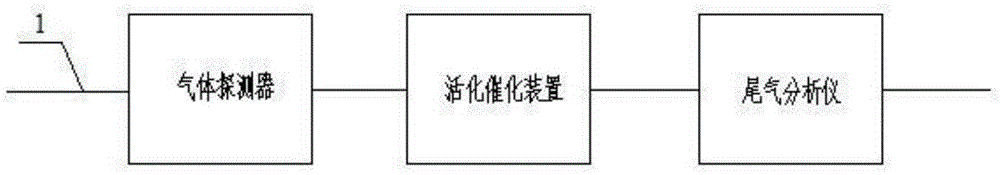

An activated catalytic device containing tourmaline for treating various low-concentration methane pollution sources

A catalytic device and tourmaline technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of low catalytic efficiency, achieve the effects of increasing specific surface area, reducing agglomeration, and convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

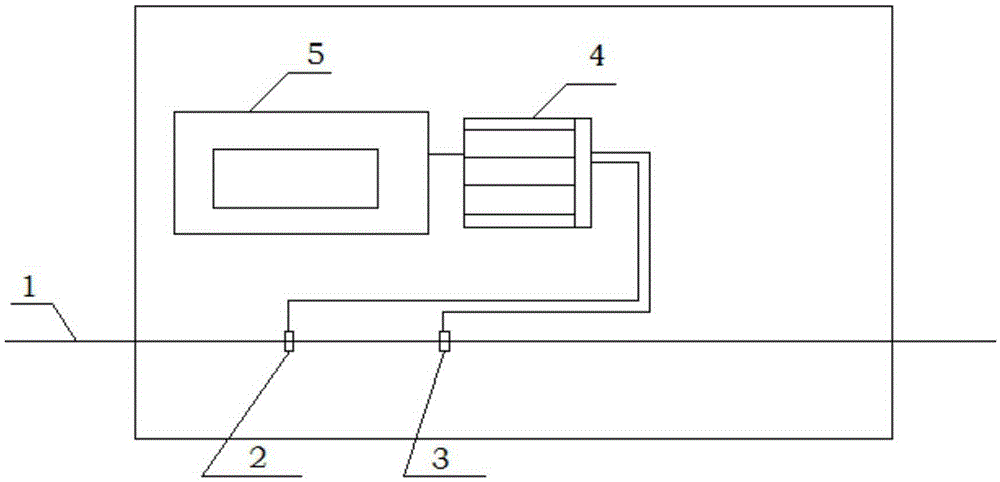

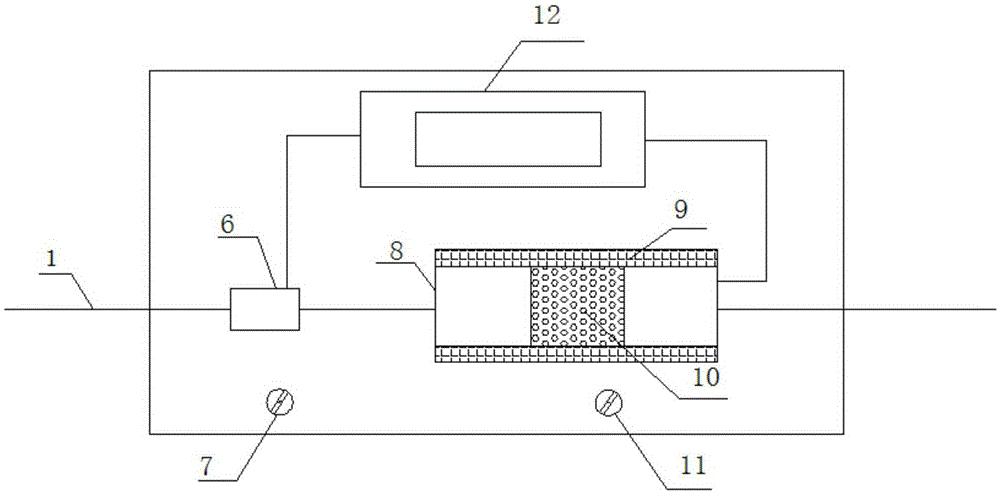

Embodiment 1

[0055] Utilize this device to process CNG automobile tail gas, at first in the catalytic reaction unit 8, load has 200 grams (2% tourmaline / 40%Co / 30%La / 15%Ce / 7%Zr / 3%Mn / 3% Al, abbreviated as LCT1) cordierite carrier 10 containing tourmaline rare earth composite catalyst, and fix it with high temperature resistant quartz wool, turn on the power, and set the gas flow rate to 12m through the flow control button 7 3 / min, feed CNG automobile exhaust, record the gas temperature and methane concentration displayed on the gas detector display 5, set the heating temperature of the heating resistor 9 to 600°C, and set the programmed heating parameters through the temperature control button 11: the heating rate is 50°C / min, at 200°C, 300°C, 400°C, 500°C, and 600°C respectively, use an exhaust gas analyzer to detect the methane concentration in the reacted gas and record the results until the temperature rise at 600°C ends, then turn off the power. In the comparative experiment, tourmali...

Embodiment 2

[0073] The difference between the second embodiment and the first embodiment is that the gas introduced becomes the exhaust air of the coal mine, and the gas flow rate is set to 60m 3 / min, composite catalyst (6% tourmaline / 36%Co / 24%La / 20%Ce / 10%Zr / 2%Mn / 2%Al, abbreviated as LCT2 ) in an amount of 800 grams; in the comparative experiment, tourmaline is replaced by non-catalytically active SiO 2 , that is, adding 800 g of loaded 6% SiO to the activated catalytic device 2 / 36%Co / 24%La / 20%Ce / 10%Zr / 2%Mn / 2%Al (abbreviated as LC2 ) gas flow 60m 3 / min, the size of the device is with reference to Table 1, and other conditions are the same as in Example 1.

[0074] Experimental results such as Figure 6 , it can be seen that the corresponding temperature of the catalytic device added with tourmaline active ingredient is 425 °C when the methane concentration is reduced by half, and the corresponding temperature of the catalytic device without tourmaline active ingredient is 455 °C ...

Embodiment 3

[0076] The difference between the third embodiment and the first embodiment is that the incoming gas becomes industrial organic waste gas, the initial methane concentration is 0.56%, and the gas flow rate is set to 40m 3 / min, the consumption of composite catalyst (8% tourmaline / 37%Co / 20%La / 16%Ce / 9%Zr / 5%Mn / 5%Al, abbreviated as LCT3) is 600 grams, the comparative experiment is selected (8 %SiO 2 / 37%Co / 20%La / 16%Ce / 9%Zr / 5%Mn / 5%Al, abbreviated as LC3) catalyst 600g, gas flow rate is 40m 3 / min, the size of the device is with reference to Table 1, and other conditions are the same as in Example 1.

[0077] Experimental results such as Figure 7 , it can be seen that the temperature corresponding to the catalytic device added with tourmaline active ingredient is 425°C when the methane concentration is reduced by half, and the corresponding temperature of the catalytic device without tourmaline active ingredient is 460°C when the methane concentration is reduced by half, indicatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com