Burning pulp cooling device for producing fermented bean curds

A technology of cooling device and fermented bean curd, which is applied in the direction of mixers with rotating stirring devices, applications, dairy products, etc., can solve the problems of resource saving and low efficacy, and achieve the effects of convenient operation, quality improvement and output improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

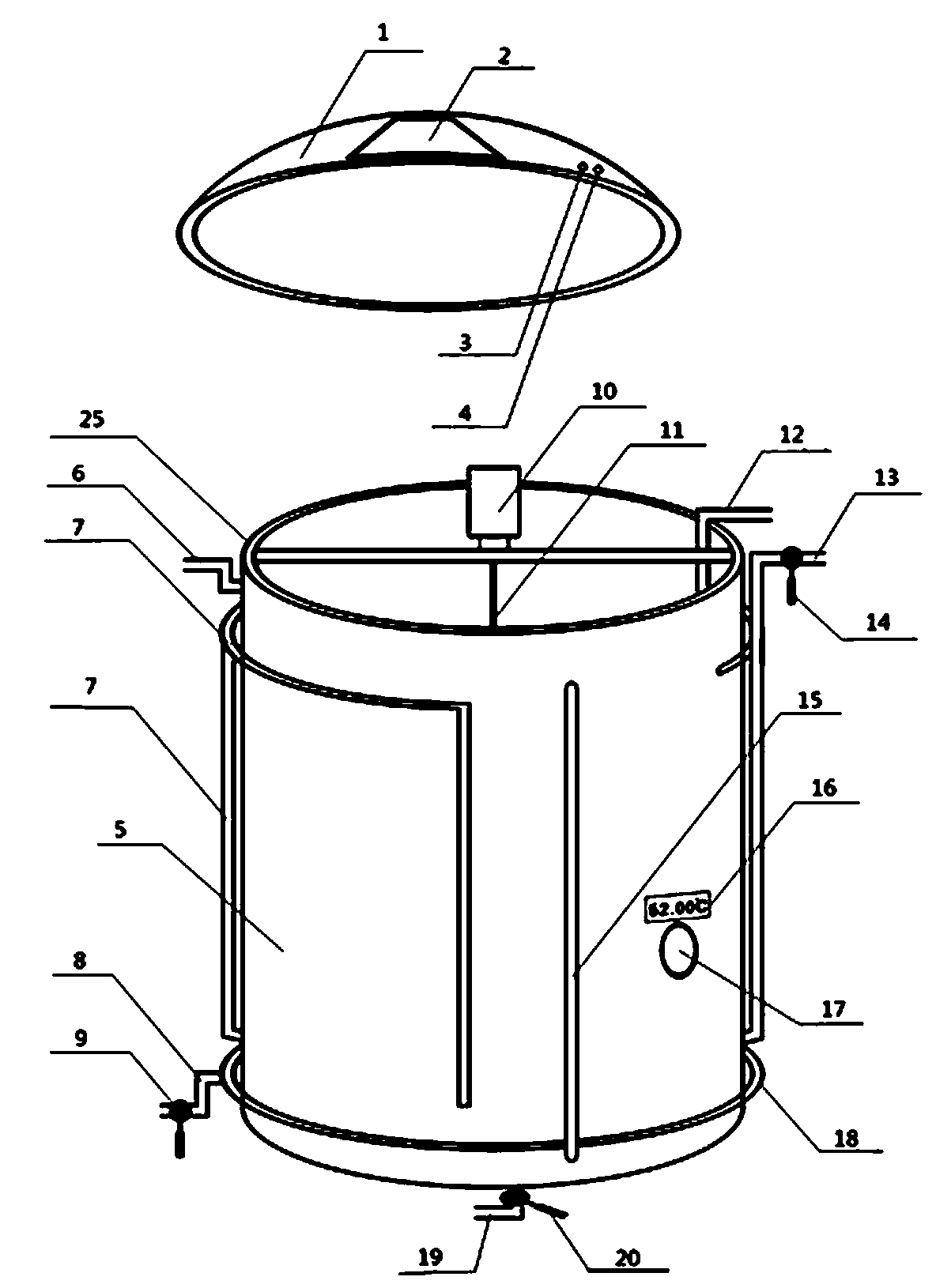

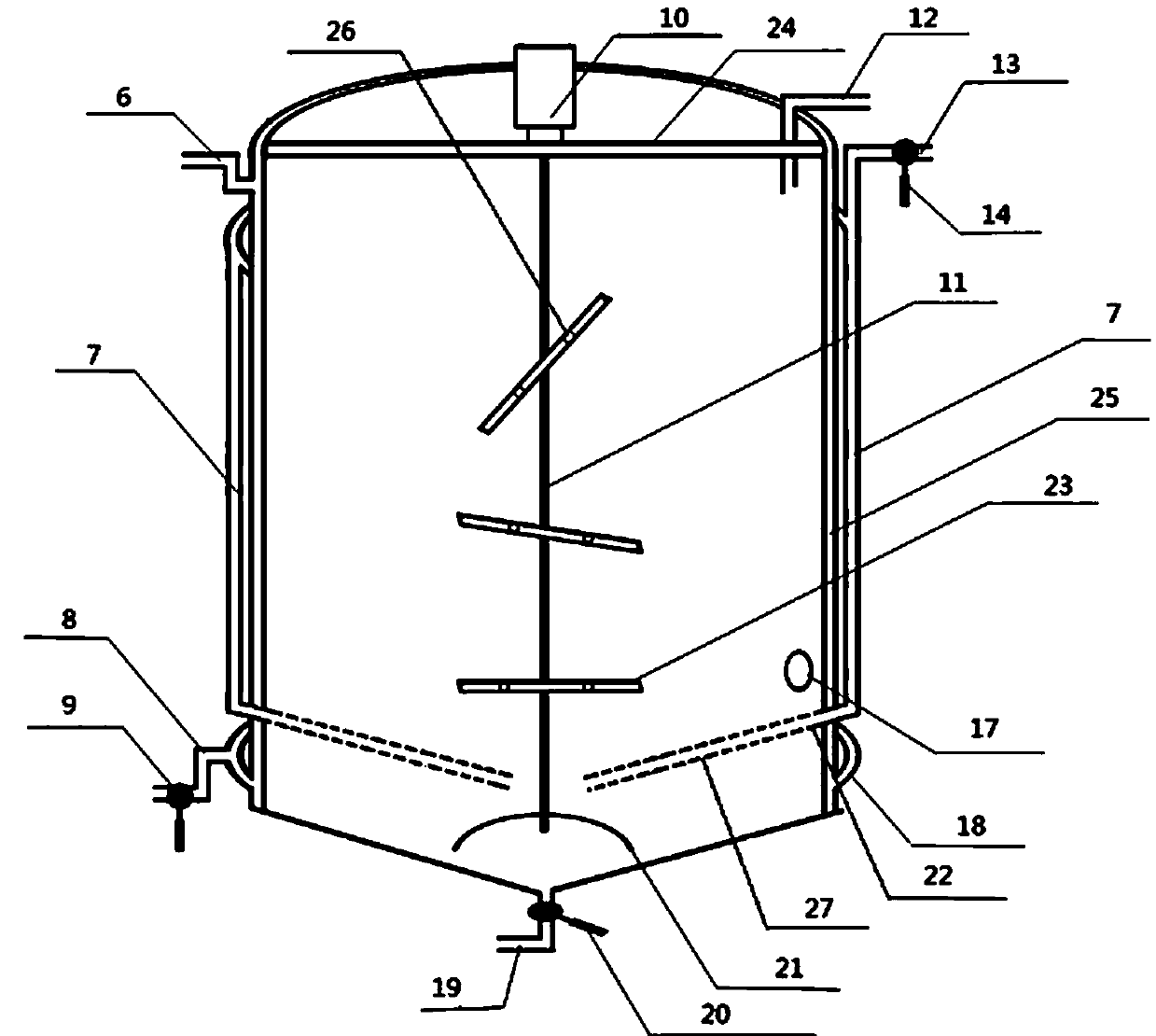

[0023] See figure 1 , figure 2 Shown, a kind of bean curd production is used for burning slurry cooling device, comprises mixing tank cover 1, mixing tank 5; The present invention is characterized in that,

[0024] The mixing tank cover 1 is set as a semi-arc cover structure, and the mixing tank cover 1 is respectively provided with an observation window 2, an air vent 3, and a grouting pipe 4; the mixing tank 5 is a cylindrical structure with an interlayer;

[0025] The upper opening of the mixing tank 5 is closed or screwed to the mixing tank cover 1; a motor bracket 24 is arranged at the upper opening of the mixing tank 5, and a reduction motor 10 is fixedly arranged on the motor bracket 24, and a stirring shaft 11 is connected under the reduction motor 10 , the lower end of the stirring shaft 11 is fixedly connected with the stirring shaft bracket 21, and the stirring shaft 11 is fixedly connected with a stirring blade 23;

[0026] The interlayer of the mixing tank 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com