System and method for rapidly forming water-soluble core

A water-soluble core and heating device technology, which is applied in the directions of core, mold composition, and mold, can solve problems such as high sintering temperature, and achieve the effect of reducing manufacturing cost and shortening development cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below with reference to the drawings and examples.

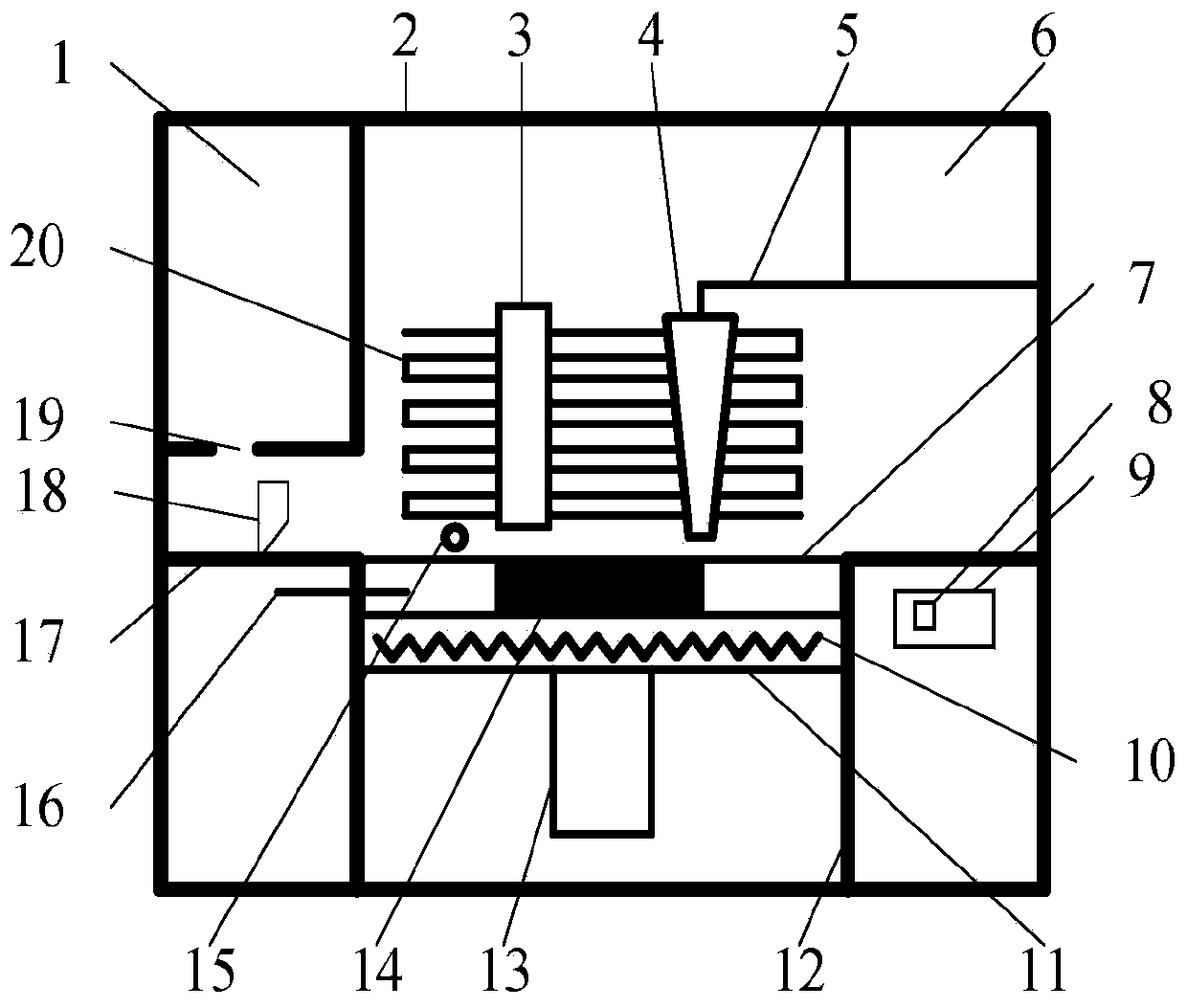

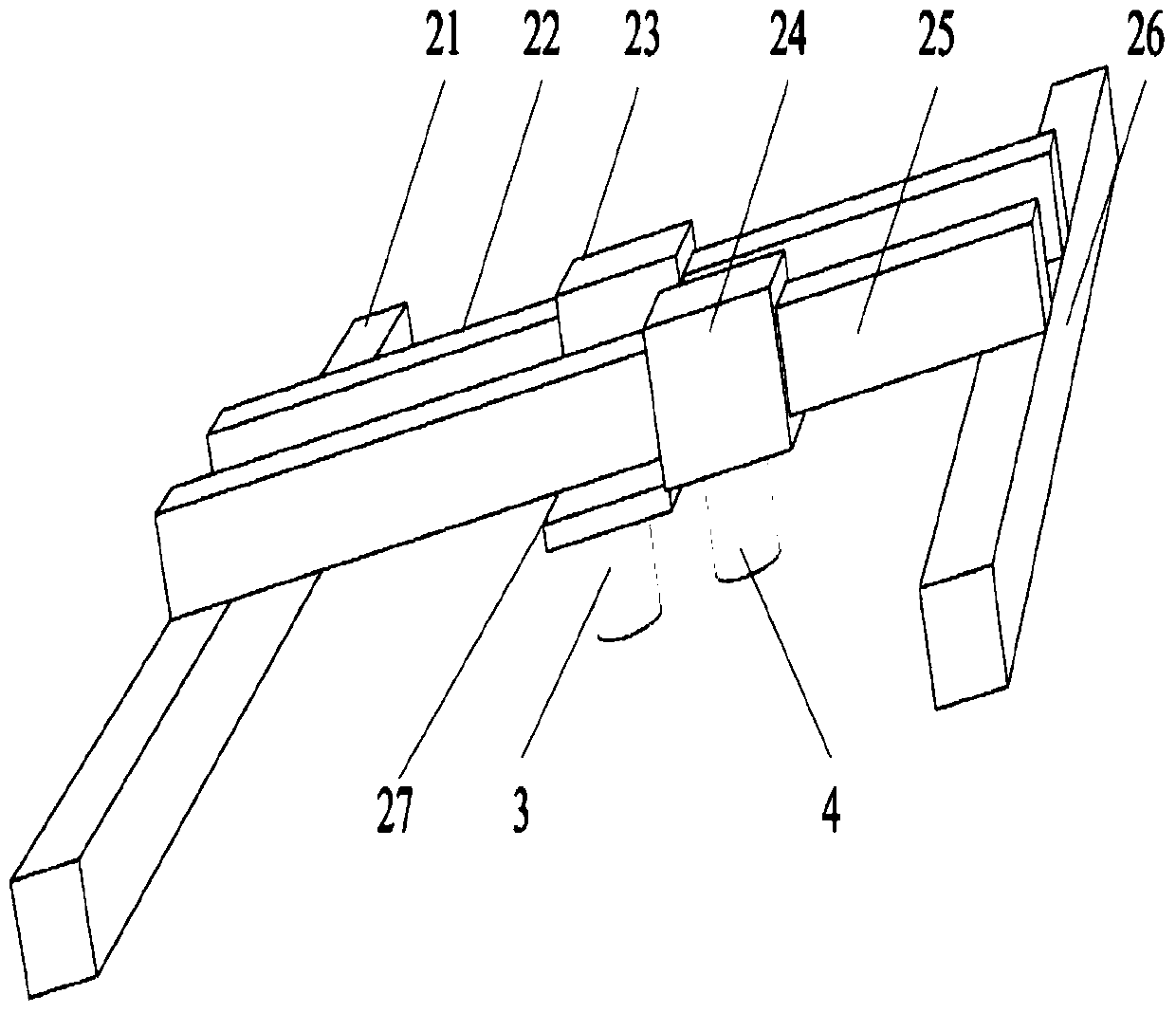

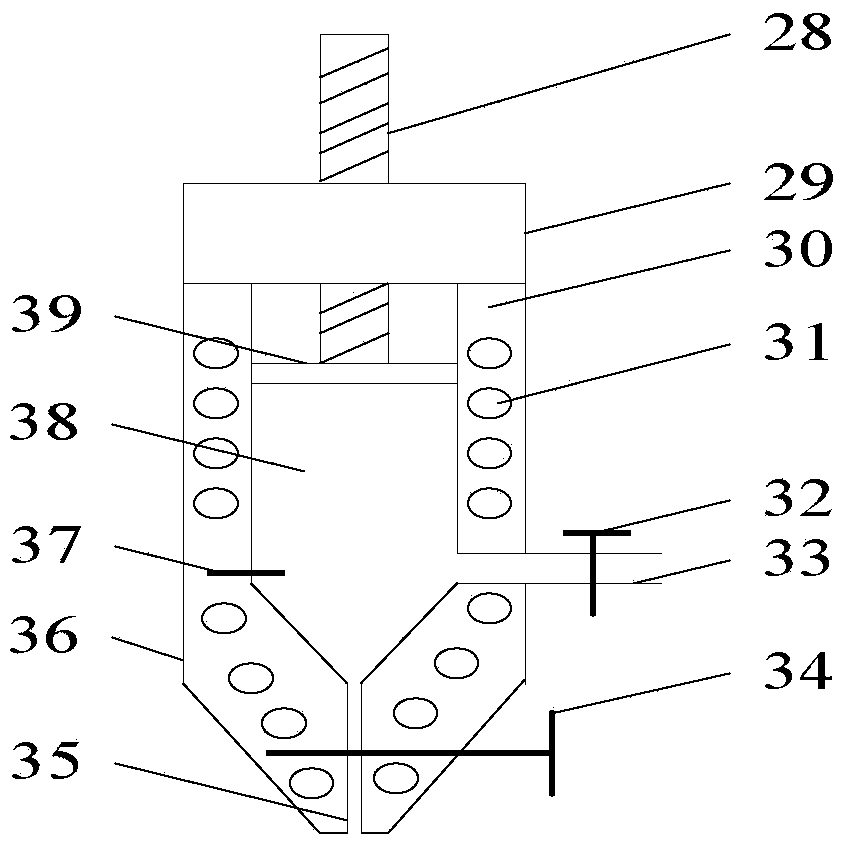

[0023] Such as figure 1 As shown, a rapid prototyping system for water-soluble cores provided by the present invention includes a box body 2, a droplet ejection device 4 and a mobile heating device 3, a mixing device 1, a material spreading device 18, a mobile heating device 3, and a space heating device 20. The powder heating device 10, the liquid distribution bin 6, the controller 9, the working cavity 12, the lifting table 11, the first temperature measuring probe 15 and the second temperature measuring probe 16. The mixing device 1 is equipped with core sand and auxiliary materials, and the mixed material can fall onto the receiving platform 17 from the discharge port 19. The material spreading device 18 is located below the discharge port 19 and above the receiving table 17, and is driven by a motor for horizontal movement. The mixture falling on the receivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com