Laser welding device

A laser welding and laser technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of temperature cannot be selectively controlled, cannot use reflow welding, etc., to ensure the consistency of quality and appearance, avoid Contact welding surface, high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

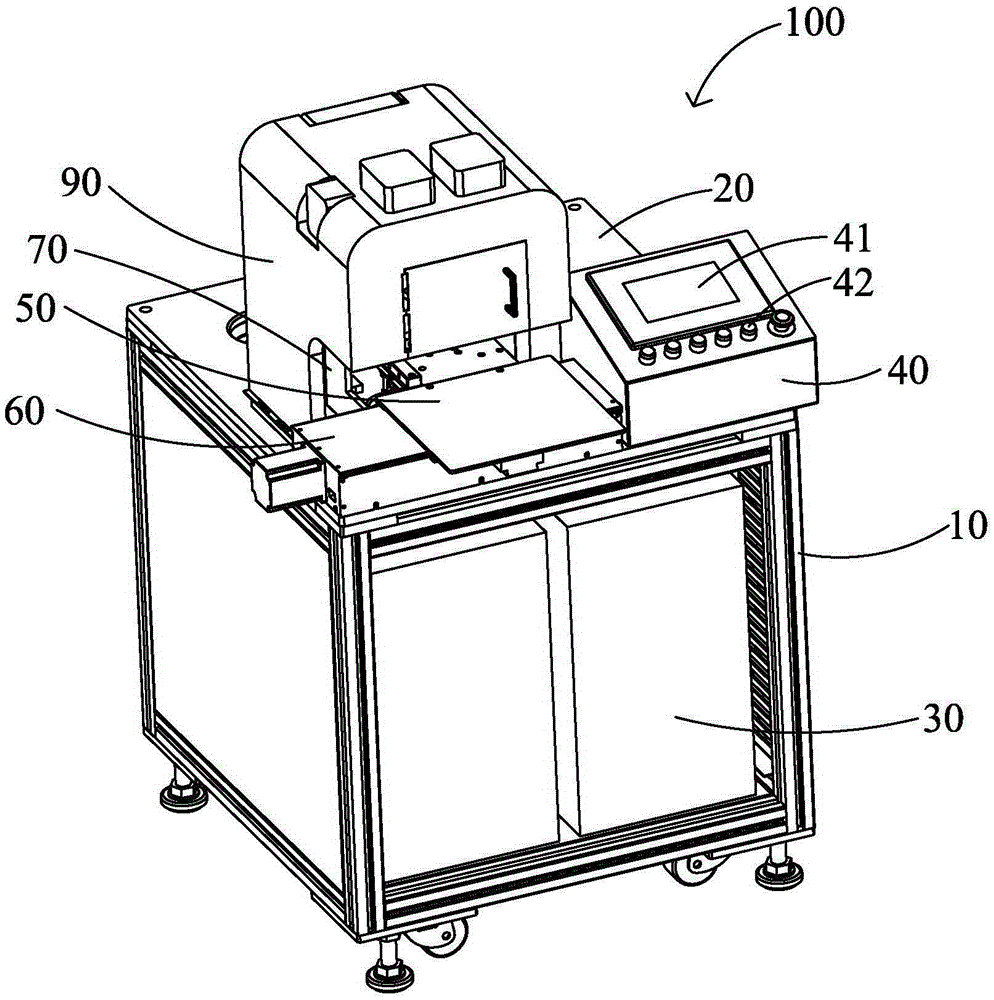

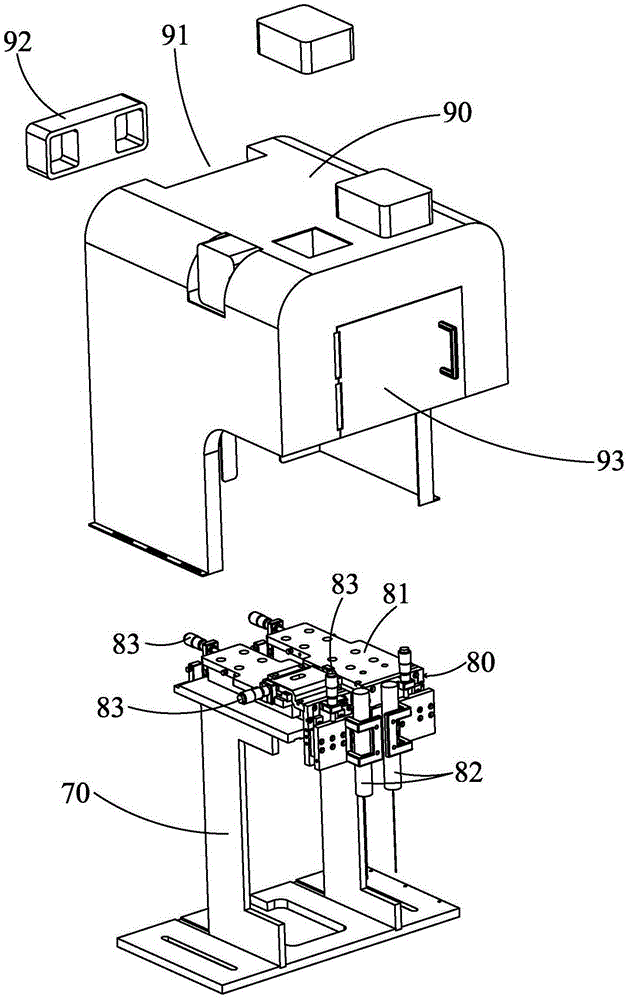

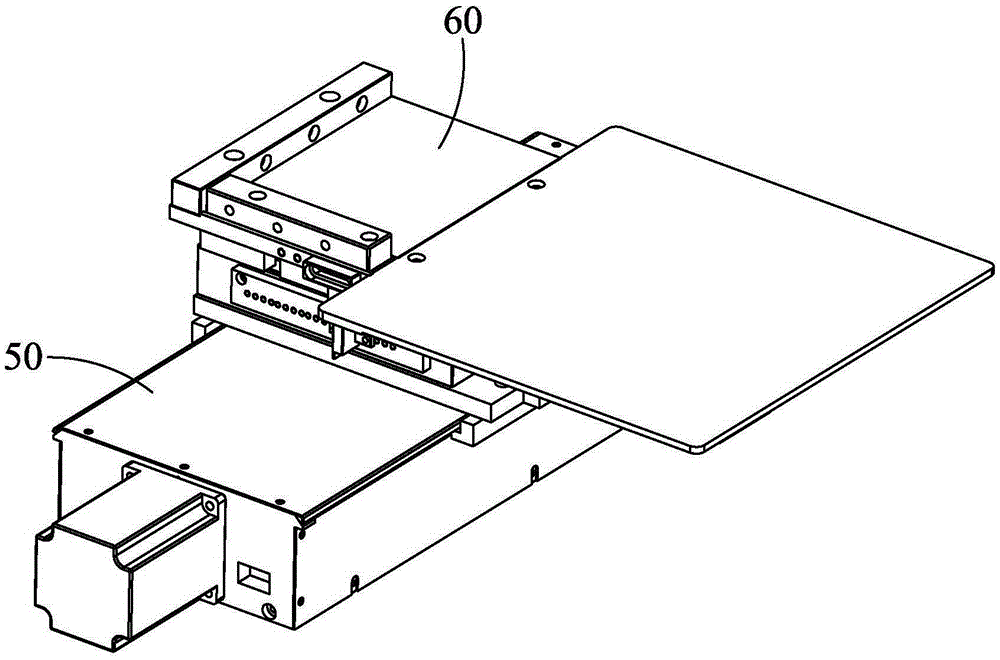

[0014] see Figure 1 to Figure 5 As shown, the present invention provides a laser welding device 100, which includes a work frame 10, a workbench 20, a laser generator 30, a control box 40, a feeding mechanism 50, a discharging mechanism 60, a bracket 70, a laser mechanism 80, and a protective Cover 90.

[0015] The workbench 20 is supported on the top of the work frame 10 , and the laser generator 30 is installed in the work frame 10 and connected with the laser mechanism 80 . The control box 40 , the feeding mechanism 50 and the bracket 70 are installed on the workbench 20 respectively. The discharging mechanism 60 is installed on the top of the feeding mechanism 50 . Laser Mechanism The laser mechanism 80 is installed on the bracket 70 , and the protective cover 90 is also installed on the bracket 70 and covers the laser mechanism 80 .

[0016] A control panel 41 and control buttons 42 are arranged on the top of the control box 40 , and the operator operates through the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap