Robot automatic grinding device

A robot and automatic technology, applied in the direction of grinding/polishing safety devices, grinding machines, grinding/polishing equipment, etc., can solve problems such as non-grinding and easily damaged cylinders, and achieve the effect of avoiding uneven weld seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

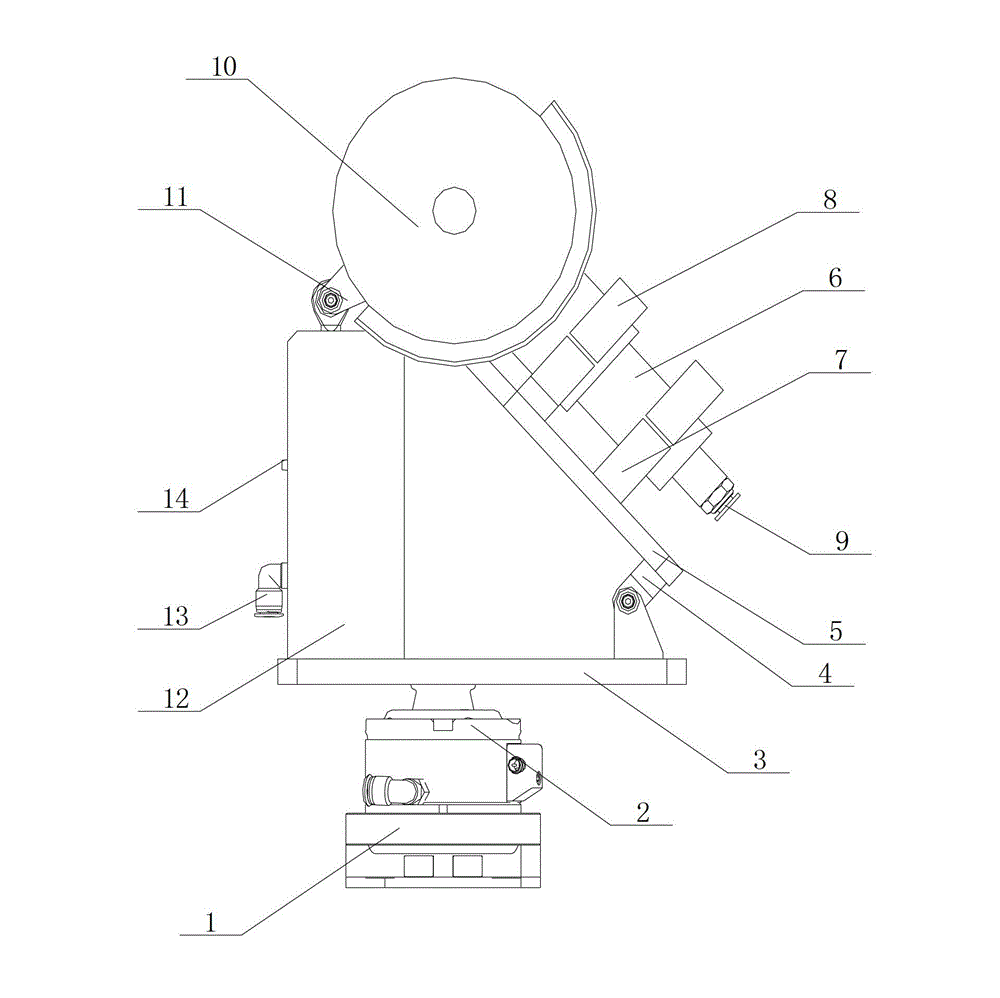

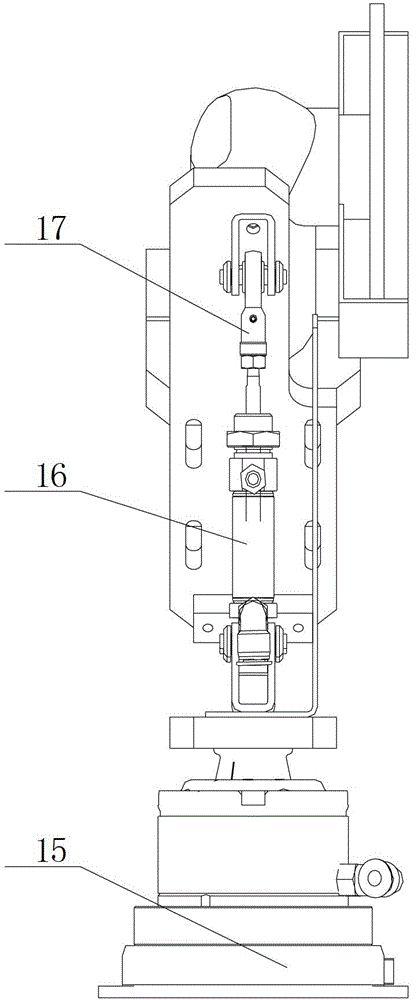

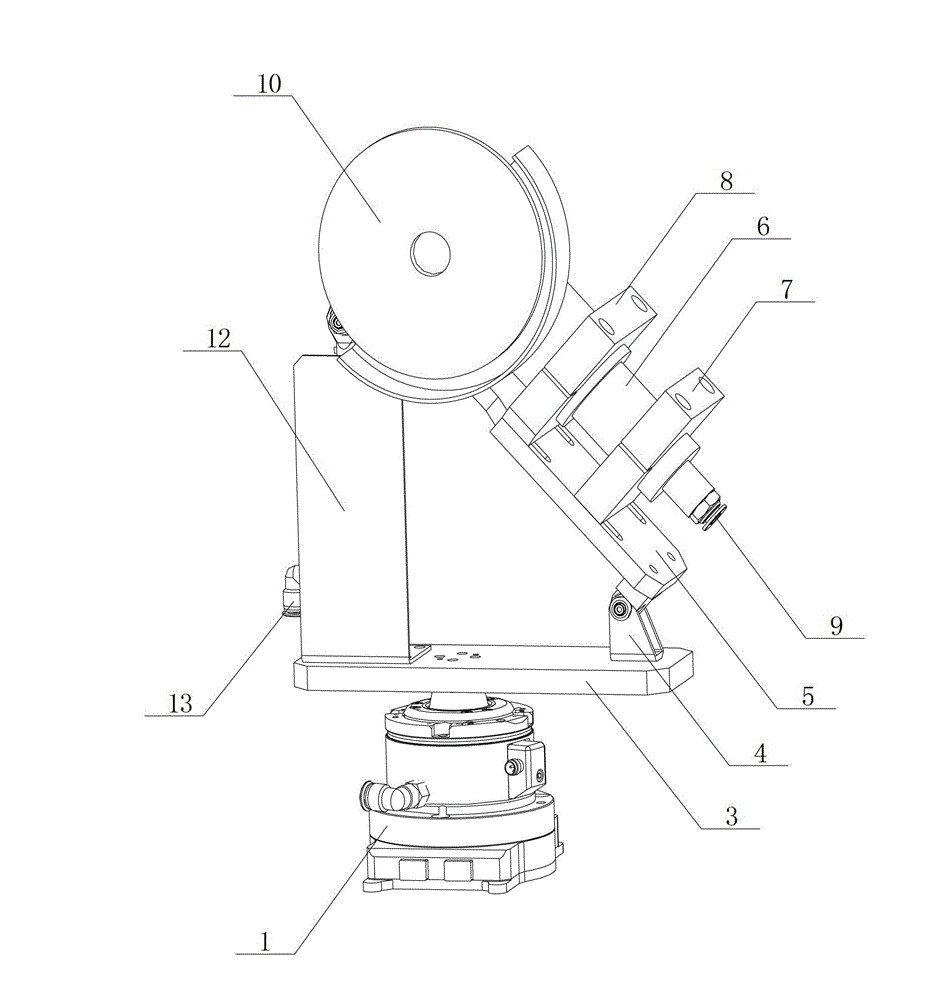

[0009] Reference Figure 1-Figure 3 , This specific embodiment adopts the following technical solutions: it is composed of flange 1, pneumatic anti-collision device 2, first plate 3, connecting seat 4, second plate 5, pneumatic angle grinder 6, first clamp 7, The second clamp band 8, the air supply connector 9, the wire brush 10, the cylinder attachment 11, the protective plate 12, the connector 13, the silencer 14, the gun block with a lock 15, the cylinder 16, the fisheye connector 17; flange plate The upper end of 1 is provided with a pneumatic anti-collision device 2, the upper end of the pneumatic anti-collision device 2 is provided with a first plate 3, both ends of the first plate 3 are provided with cylinder accessories 11, and the connecting seat 4 is fixed on one end of the first plate 3. On the cylinder attachment 11, one end of the second plate 5 is fixed on the connecting seat 4, the other end of the second plate 5 is fixed on the fisheye connector 17, the fisheye ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com